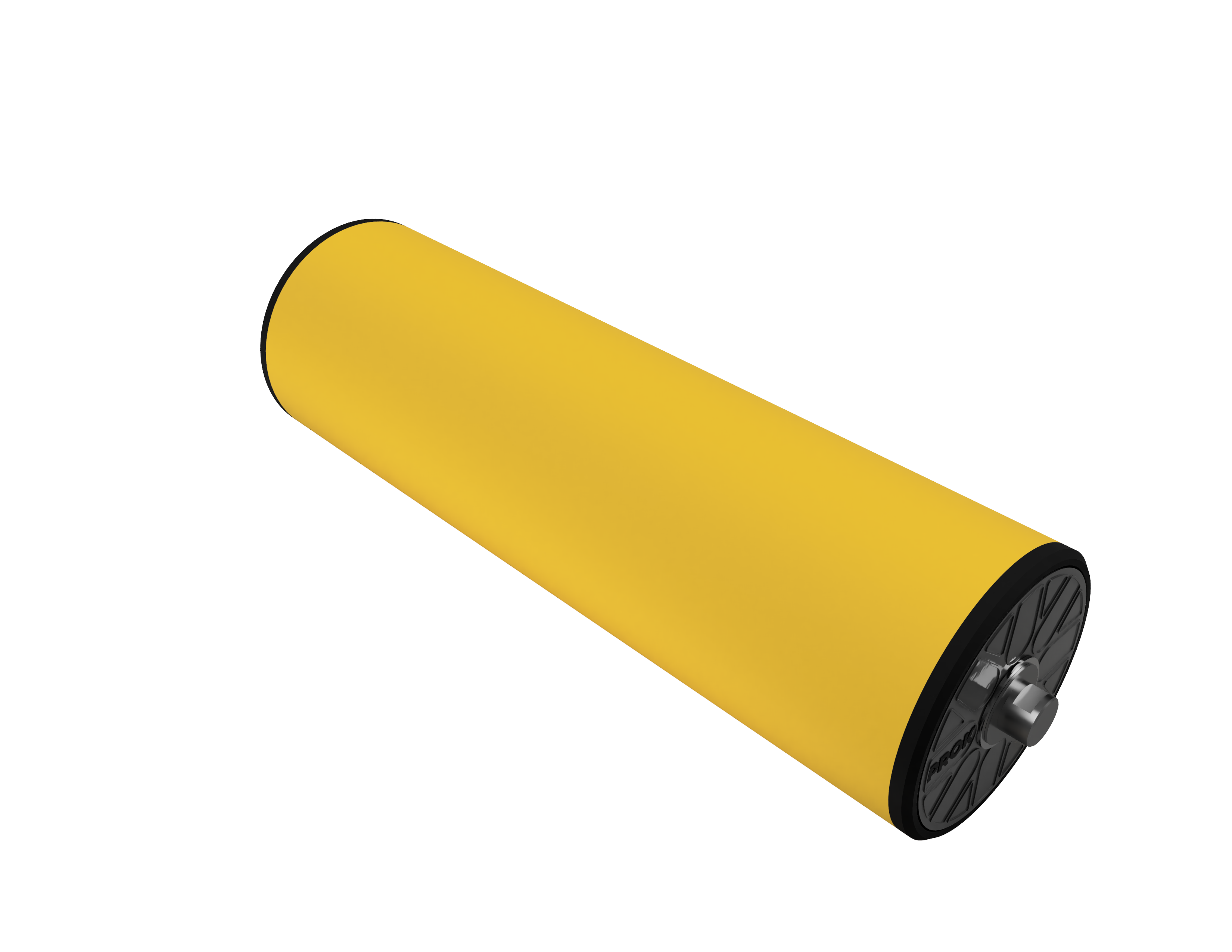

A high-performance composite roller designed for smart mining operations looking to reduce downtime, lower maintenance costs, and improve site efficiency.

Optimised for High-Performance

PROK HDPE Rollers are engineered for demanding, high-speed, and large-tonnage applications. Built with a resilient polymer matrix, these lightweight yet durable rollers enhance productivity, minimise downtime, and reduce risks to both personnel and conveyor belts.

Specifications

- Tube Diameter: 127mm – 219mm

- Bearing Sizes: 6305 – 6312

- Tube Material: High-Density Polyethylene (HDPE)

- Shaft Sizes: 26mm – 62mm

- Seal Performance Testing: Based on DIN 22112

Key Features & Benefits

Advanced HDPE Construction

Manufactured from a reinforced polymer matrix, the PROK HDPE Roller offers superior tensile strength while remaining significantly lighter than traditional steel rollers, reducing belt wear and energy consumption.

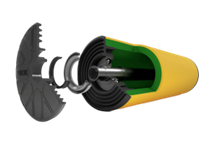

Integrated Sealing System

A non-metallic housing and advanced three-tiered sealing system, featuring a multi-labyrinth and contact seal, provide maximum protection against contaminants. Independent testing confirms that PROK HDPE’s sealing technology delivers 6x better performance than other composite rollers on the market.

Visual Wear Indicator Technology

As a world-first innovation, PROK’s HDPE rollers feature a visual wear indicator, enhancing maintenance planning. The outer PROK yellow tube and inner green layer work together as a wear indicator, allowing maintenance teams to schedule changeouts proactively.

Friction Welded Bearing Housing

The friction-welded housing fuses seamlessly with the tube, eliminating common bearing housing failure modes. This design transitions stress more effectively, preventing dislodgement and creating an impenetrable seal against contaminants.

Don’t Get Left Behind

We never stop innovating, and neither should you. Upgrade your conveyor system with PROK HDPE Rollers today to stay ahead in efficiency and reliability.