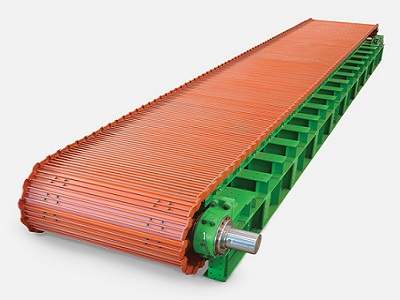

The MMD heavy-duty apron plate feeder is designed to handle high-impact loads created from large ROM material directly dumped. Used in many types of mineral and ore applications around the world, plate feeders are key to providing reliable and controlled throughput.

Directly load at anytime

The MMD Feeder’s unique design allows dumping of run-of-mine material even when the feeder is running empty. The ability to load at anytime delivers continuity and flexibility of operation for maximum production and efficiency.

Heavy-duty design

Due to its strength and impact resistant design, the feeder has the versatility to be loaded by various methods from trucks to draglines. Its reliability and robustness have proven to give many years of trouble free operation.

Regulated throughput

Apron feeders commonly regulate the feeding rate to optimise plant capacity. Driven by variable speed drives they provide complete control of the production throughput.

Our complete range of feeders caters for a variety of capacities and feed sizes.

The cleanest apron feeder

The use of the more resilient and durable rolled plate flights produces tighter tolerances than commonly used cast or fabricated plate flights, hence minimizing inevitable leakage between plates.

Customised application

For optimum performance and efficiency, our apron feeders are tailored to each application.

In-built fines retrieval (optional)

To completely eliminate manual clean-up, an automated fines retrieval system or separate fines conveyor can be integrated to pick up any fines and deliver them back into the main flow of material.