Timberland Equipment is a global leader in the integrated design, manufacture and support of custom-engineered winches, hoists, sheaves, derricks and tensioning equipment for the world’s most challenging infrastructure and capital equipment projects. Our products are part of many of today’s largest projects in:

- Shaft sinking operations

- Personnel and materials hoisting

- Mine rescue

- Rope installation and tensioning

- Tension stringing

- Heavy construction

- Marine operations

- Offshore oil and gas

- Trenchless technology

Custom-engineered winches for challenging mining environments

With the benefit of over 8,000 projects completed to date, our customer focus and field experience bring us a unique understanding of the many dimensions of risk that our customers face in significant capital projects of this nature. Our expertise provides customers with the answers they need to minimize their risk while they maximize the reward from their opportunities.

Shaft sinking winches

We provide fully integrated sinking winch systems with local and grouped control technology. Electric / VFD powered, electric-hydraulic and even diesel drive systems are available.

Timberland sinking winches have been providing reliable operation for decades, installed in some of the most demanding applications around the world. Custom-engineered solutions are available for any capacity and unique frame designs allow ease of disassembly for shipping and for transport underground.

Material and personnel hoist systems

Timberland provides unique hoist designs that provide selective use for conveying materials or personnel. Respective mode selection provides maximized flexibility of the hoist and adherence to both sets of applicable code requirements. Operator-friendly control stations with HMI screen display are available.

Mine rescue hoists

Timberland is the industry leader in providing rescue hoist systems for all underground mines, and offers electric, electric hydraulic and diesel-powered hoists arrangements. Our hoists feature control platforms for conventional operator control and automated call from below’ technology. Designs of rescue hoists include:

- Skid mounted

- Pedestal mounted with bearing for rotational option

- Trailer mount systems

- Fully portable truck installed system

Timberland also manufactures all related accessories including man cages, booms, and deflection sheaves.

Rope installation and tensioning equipment

Timberland is well recognized for twin bullwheel rope tensioning systems, used in conjunction with our reel winders for wire rope installation and rope change procedures. We provide tensioning of up to 60,000lbs to ensure proper rope installation and safety. Tensioners are also used to remove rope from hoists.

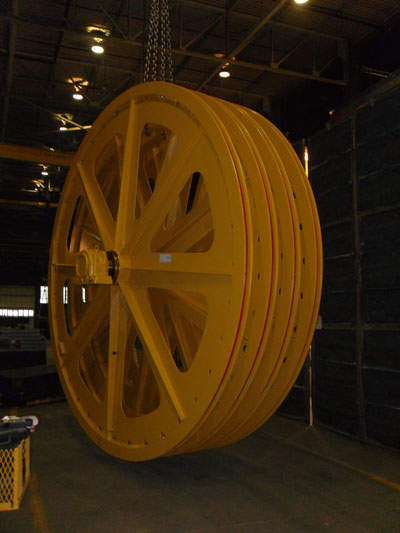

Head sheave and deflection sheave equipment

Timberland designs and manufactures a complete range of head and deflection sheaves, including solid, split and multi-piece designs up to 6,100mm (240ft) in diameter. Options include replaceable steel or synthetic liners, encoder-ready features and centralized grease provisions.

Timberland’s engineers utilize the latest technology in FEA and solid modeling design tools for maximum reliability and longevity.

About Timberland

Timberland is ISO 9001 certified and employs a full-time quality control department. All equipment is tested in-house, on specifically designed fixtures and test towers. Timberland has experience of working with all certifying authorities such as DNV, BV, ABS and Lloyds.

Our factory service technicians travel the world assisting customers during commissioning and start-up operations. Timberland’s worldwide support network ensures that we will have a representative on site to service our equipment when required.