Jensen Ventilation AB manufactures ventilation ducting tubes for mines, tunnels and underground operations. The ventilation tubes are designed and constructed according to the requirements of each site.

Jensen makes ventilation ducts from a woven or knitted polyester yarn coated on both sides with softened PVC. The PVC coating makes the ventilation duct air and water-tight, and protects from UV radiation and the chemical effects of light.

Custom ventilation shaft ducting material

To ensure customers receive a ventilation tube suitable for their operation, Jensen produces a range of very light, light, standard and extra strong ducting fabrics. The materials offer a range of tensile strengths and are fire-retardant. Anti-static and low-friction versions are available.

All materials undergo quality control testing.

Duct connectors and joints

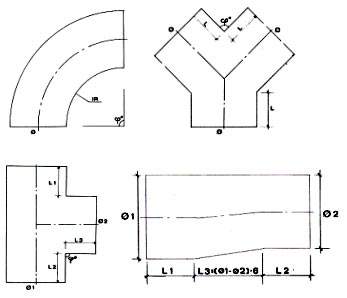

In addition to the tube shaft, Jensen also manufactures a wide selection of bends, Y-tubes, T-tubes and reductions to provide a complete ventilation system for mine sites.

For connecting ducts, JP Jensen Ventilation offers three options:

- Traditional connection with a galvanised coupling clamp outside and one or two steel rings welded in the end of the ducting

- Specially made zip-joint – very strong and durable

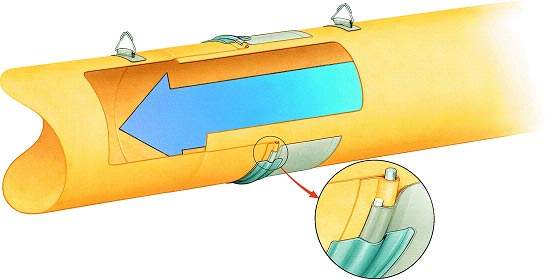

- The JP-Superjoint

JP-Superjoint is a patented solution for creating a straight airflow in a flexible ducting. A unique solution that eliminates the two most common energy problems in underground ventilation systems: airflow (turbulence) and leakage in the joints.

Depending on the size of ventilation system, JP-Superjoint gives savings in the range of 10% to 20% of the overall energy costs.

Ducting system and ventilation tube welding seams

Jensen Ventilation has developed an effective method for welding sections of ventilation tubes. The company has used this patented technique since 1981, and the 40mm-wide welding seam is proven to make the seam almost the same strength as the material itself.

Ducting system assembly

Steel hooks are to be hooked on a longitudinal steel wire, fastened by rock bolts in the tunnel ceilings. The suspension is constructed in such a way that if there is an extraordinary force on the ducting, the steel hooks will break and leave the reinforcements undamaged.

Steel hooks are available as spare parts and can easily be reassembled on the ducting.

Ventilation duct repair kits

Mine, tunnel and underground sites see a great deal of industrial activity and large, heavy machinery can cause damage to ventilation ducts. Ventilation ducts need immediate repairs to ensure they provide a reliable and high level of fresh air to workers.

Jensen supplies ventilation duct repair sleeves to cover a large damaged section. Repair kits contain everything you need to quickly and effectively carry out a smaller repair, such as:

- PVC material

- PVC adhesive

- Cleaning paper

- Brushes

- Spakel

- Needles

- Thread

- Hooks

- Suspension patches

Hot air guns are also available, which are necessary for undertaking duct repair work, as well as steel couplings, zip connectors and Velcro.

Jensen’s in-depth experience reliable air supply equipment means the company can advise on the tube’s design, produce the fabric and construct the ventilation system.

Depending on the customer’s site, Jensen can recommend either a single large-diameter shaft or two smaller shafts, in order to gain the maximum air supply from the minimum fan RPM. This reduces costs and increases energy-efficiency.

About JP Jensen Ventilation

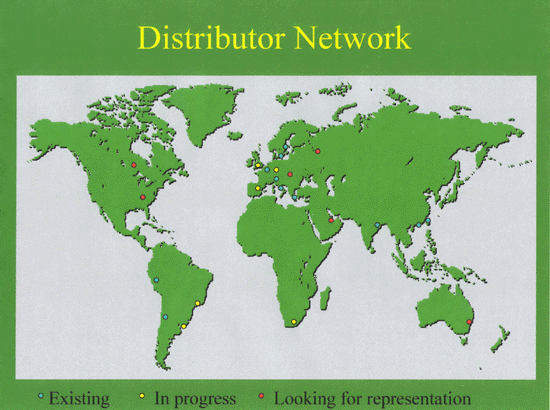

JP Jensen Ventilation has head offices in Malmö, Sweden, and is part of the AB Chr Jensen Group.

The company was formed in 1879 and is one of the oldest companies in the world specialising in processing PVC-coated material. Since the 1970s, JP Jensen Ventilation has supplied flexible ducting systems to the mining and tunnelling industries.