Schlam Launches the Hercules EXO Dump Body with Increased Payload & Double the Service Life

WA-based mining product and services supplier, Schlam today launched the Hercules EXO – a next-generation mining dump body that offers iron ore miners both a higher payload potential and longer service life.

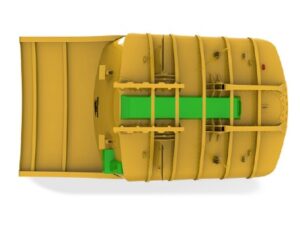

The Hercules EXO is a 240t class iron ore specific dump body that is 20% lighter than the company’s already class-leading Hercules. The decreased weight gives miners a greater payload potential, while a complete redesign and innovative material selection have resulted in a 100 per cent increase in service life.

Schlam CEO, Matt Thomas, says that miners had to compromise between payload and longer service life before the Hercules EXO arrived in the market.

“The Hercules EXO is an ultra-lightweight body that maximises payload without sacrificing body life or requiring the addition of wear packages.”

“It is the culmination of 20 years of continuous improvement and innovation wrapped into one high-performance dump body,” Matt stated.

Schlam’s engineering department completely redesigned the previous Hercules to reduce weight in all non-wearing components.

“The team looked at the structural componentry individually to reduce weight so we can maximise steel thickness in the wearing areas, where it really matters.”

“Using hybrid steel thickness, combined with Hardox® 500 Tuf steel from Swedish steelmaker SSAB in the wearing areas means that the EXO has a service life more than double other lightweight options.” Matt continued.

The extra service life has three added benefits: cost, safety, and the environment.

Compared to the heavy-duty products on the market that utilise liner packages, the payload potential of the Hercules EXO is far more significant. It also does not require the labour-intensive wear plate replacement events needed to achieve target body life.

“When you factor in stored energy, working at heights, craneage, welding and more, liner replacement is high-risk work. The Hercules EXO removes these risks making it a safer option for miners.” Matt explained.

The EXO project was completed in close consultation with Schlam’s customers, who revealed that carbon impact is increasingly coming to the forefront of their concerns.

“It’s no secret that steel production creates a lot of carbon. However, having a dump body that uses less steel in the original manufacturing process and only needs to be replaced every eight years rather than every four has a massive net benefit on carbon production,” said Matt.