Sovatec Industriale specializes in the manufacture of screens for the quarry and mining industry. Sovatec offers a complete range of quality screening media that includes, as well as woven wire screens of high tensile steel or stainless steel and polyurethane screens, also rubber screens, metal plates and steel-rubber plates.

Since its foundation in 1973 Sovatec has widened its production following the developments of technology and the needs of the clients. From its plant in Italy, Sovatec exports more than 50% of its production to 60 different countries.

Sovatec produces screening media for the quarry and mining industry ready for installation on machines of all type, size and manufacturer, supplying all the most important manufacturers and collaborating with them to develop the most effective solutions for screening.

Sovatec screens are used in the recycling, steel, coal, food, chemical, heat-treating industries, as well as sand and gravel quarries and mines.

Wire screens of high tensile steel and stainless steel

Sovatec manufactures calibrated and shape-retaining meshes of round wire of both high tensile steel 160kg/mm / 180kg/mm according to DIN 17223 – EN 10270 and stainless steel AISI 304 – 316 – 310, etc.

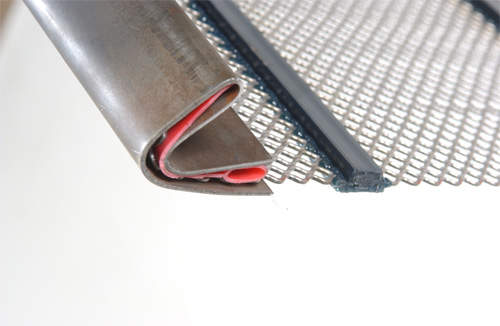

The woven wire screens are available in rolls and standard panels, or cut to size with or without tensioning folds. All types of crimps according to DIN 4192 / ISO 4783-3 are available. Also, all types of tensioning folds are made in relation to the different types of screening machines.

The size range of Sovatec’s wire screens spans from stainless steel fine mesh, to mesh 100mm x 100mm / wire 12mm. For each mesh, many different wires can be chosen according to the required strength and open area. Rectangular meshes are also available in all sizes.

More than 10,000m² of mesh is kept in stock ready for a quick delivery.

Piano wire screens / non-blinding screens

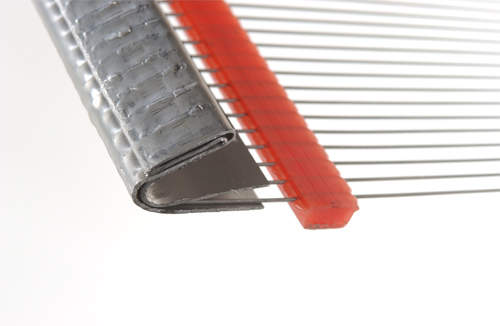

Sovatec’s non-blinding screens, also known as self-cleaning screens or harp screens / piano wire, are formed by longitudinal wires, kept at the right distance by means of a connecting weft. They are based on the principle of the spring back of the single wires and on the property of a stretched wire to be put in oscillation with its own frequency.

The longitudinal wires of our piano wire screens / non-blinding screens can be straight or waved, with waves on the same plane of the screening surface, leading to opening approximately square for an exact calibration of grains. The bindings can be made of polyurethane or, where screens work at high temperature, made of weaved wires.

Made of high tensile or stainless steel, Sovatec’s piano wire screens / non-blinding screens are particularly suited to improve the screening efficiency and to avoid clogging with wet or hygroscopic materials.

Polyurethane screens, for screening and dewatering machines

Sovatec manufactures polyurethane screens of all types and dimensions, to fulfil the requirements of its clients in many countries. Before manufacturing, each polyurethane screen is carefully designed on the basis of the information received from the client. All the characteristics of the polyurethane screens are defined: dimensions, thickness, apertures (square, round, slot), steel frame, blind zones, fixing holes, hooks, shore hardness, polyurethane quality.

Only high-quality polyurethanes are used to guarantee the highest performance in terms of abrasion resistance, cut and tear resistance, flexibility and resilience. Sovatec is able to produce polyurethane screens of all types: tensioned, self-supporting, modular panels with all different locking systems, flip-flow mats, dewatering panels etc.

A wide range of polyurethane accessories for screening machines, such as bars, plates, wedges, washers, are kept in stock ready for a quick delivery to our clients.