Plant Solutions, Sensor-Based Sorting Machines

An overview of REDWAVE mineral sorting technology.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

BTW Plant Solutions specialises in mineral processing, material handling systems, and the REDWAVE optical sorting technology.

As an innovative partner for turnkey projects, modification and extensions to existing plants and powered by REDWAVE, we offer our own industrial proved in-house sensor-based sorting machines.

The company operates worldwide and headquartered in Austria. It maintains branch offices in Germany, the US, China and Singapore.

The REDWAVE mineral sorter recognises the target material based on typical characteristics such as colour, transparency, atomic density (elemental composition) and conductivity.

Designed for mineral handling and sorting applications, the sorter aims to enhance the quality and identification of a wide range of minerals, ores and gemstones such as limestone, quartz, talc, gold, nickel, willemite, magnesite, emeralds and diamonds.

Advantages of using the REDWAVE sensor-based sorting solutions include:

• Single or double side scanning

• Up to 2,000mm working width by charge-coupled device (CCD) technology

• Identification and sorting of different materials according to colour, brightness, transparency, and element composition with the leading REDWAVE XRF technology

• High efficiency, recovery rates and availability

• High throughput with maximum recovery of materials

• Fast payback period

• Cost-effective dry and wet sorting technology

• Multi-sensor unit to sort minerals in the same colours

The combination of the newly developed X-ray fluorescence technique with a high-resolution RGB camera offers unique opportunities worldwide for recognition at the REDWAVE sorting machine.

By combining the two techniques, it is possible for both the objects and their color and the elemental composition to be used as sorting decision.

Our customers can test their products with different REDWAVE mineral sorting machines at our test centre. Using our REDWAVE advanced sorting units, we ensure the highest grades in your end products.

Accurate raw material processing is a prerequisite for a high-quality product.

BTW Plant Solutions performs optimised crushing experiments that in collaboration with our innovative partners.

We are experts in:

• Drying / cooling

• Crushing

• Screening and sieving

• Conveying

• Control systems

• Sorting

• Sensor-based sorting powered by REDWAVE

BTW Plant Solutions performs the design, delivery and assembly of the crushing, screening, mixing and batching processes, as well as the realisation of rail car discharge stations, landfill sites, reloading points and terminals for trucks and rail cars.

We provide conveying systems within the mining, non-metallic minerals and metallurgical industries, as well as the power sector.

Our processes include:

• Curved belts

• Belt feeders

• Belt or chain bucket elevators

• Conveyors: vertical lift, apron, belt and chute

The manufacture of dry construction materials such as cement, fillers, mortar and plaster requires a thorough knowledge of the dosing, weighing, mixing, packing, storing and controlling processes.

BT-Wolfgang Binder designs, assembles and supplies customised mixing plants within the specified time, ranging from materials handling and stockpiling, precise batching and weighing systems, to packaging plants.

We also offer drying, screening, weighing, dosing and storage services.

BTW Plant Solutions and REDWAVE are trademarks of company BT-Wolfgang Binder.

An overview of REDWAVE mineral sorting technology.

The Redwave mineral sorter has been developed for the sorting and handling of different minerals to improve the quality. Identification and sorting of various minerals, ores and gem stones such as limestone, quartz, talc, gold, nickel, willemite, magnesite, emeralds and diamonds etc.

Founded in 1959, Grecian Magnesite is a magnesite specialist and one of the world's leading producers and exporters of magnesia.

On 23 May 2019, REDWAVE and BTW Plant Solutions, departments of BT-Wolfgang Binder GmbH, opened their new, state-of-the-art, six-storey office building at Wolfgang Binder Straße in Brodersdorf.

Discover the sensor-based sorting technology for the mining industry.

The strong demand continues.

Opening of the biggest plastics sorting plant in Austria.

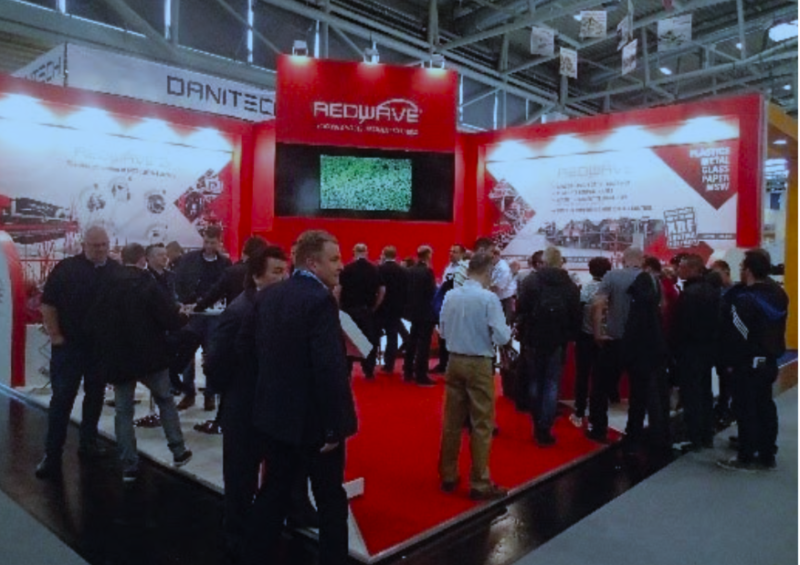

REDWAVE presented the new REDWAVE 2i at IFAT 2018 in Munich, Germany.

At the Stena Nordic Recycling Center (SNRC) in Halmstad, Sweden, REDWAVE XRF/C technology has been in use since the beginning of the SNRC.

BT-Wolfgang Binder has been supp¬lying voestalpine with a wide range of products for 13 years now.

Over the past 20 years BT-Wolfgang Binder GmbH has positioned itself as a reliable and experienced general contractor, realising plants within the fields of mixing, sand processing, and conveyor technology.

Founded in Milan in 1937, MAPEI is one of the world leaders in the manufacturing of adhesives, sealing and chemical products for the building industry today. Currently, 70 subsidiary companies with 64 factories belong to the MAPEI group, which is active in more than 31 countries on all five continents.

Feichtinger KG is a private company from Esternberg (Upper Austria) and provides approximately 30,000t of quartz a year to the RW silicium GmbH.