gaustec® technology has been revolutionising ore processing around the world for many years.

Continuous research and development has resulted in major improvements in wet high-intensity magnetic separation. With an unsurpassed throughput capacity of up to 1,400t per hour, the new gaustec-GHX is efficient and cost-effective at processing low-grade iron ore into marketable high-grade pellet feed fines.

Increased global demand for raw materials, combined with a steady decline in the quality of the mineral raw materials in demand, has generated new interest in the development of high-intensity magnetic separators with larger capacities.

The gaustec-GHX offers an innovative solution, due to its numerous improvements, vastly simplified maintenance, reduced energy consumption, smaller plant layout and greater flexibility through variable customised settings. That is all in addition to its gigantic throughput capacity of up to 1,400t per hour. The GHX-1400 has fulfilled its objective to provide a solution for improving iron ore processing technology worldwide.

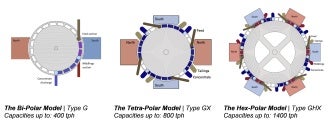

This cutting-edge technology has established a new world record in this class of magnetic separators. The following schematics show the development from the basic bi-polar type to the tetra-polar type and now the hexa-polar type with the corresponding maximum capacities.

Although low-grade iron ore mines will benefit from the new technology, the main focus is on reclaiming low-grade iron ore tailings from ponds, with huge positive environmental and economic benefits.

Based on the new gaustec-GHX technology, construction work on a processing plant designed to process iron ore tailings with a 45% iron grade began at the Itaminas mine in Brazil, at the end of 2012. The plant went into operation mid 2013 with a feed capacity of 480t per hour and three processing stages (rougher, cleaner and re-cleaner) in a single unit at 2.5mm matrix gap. The quality of the pellet feed product reached 65% iron with an average tailings grade of 35%, approximately equivalent to a 30% plant yield.

The excellent performance of the first gaustec-GHX led to the construction of a second plant of the same type, for further downgrading the tailings to less than 20% iron. This plant is scheduled for commissioning this year.

allmineral has been successfully operating in the market for more than 25 years and is a leading supplier of processing plants and equipment for the mining industry worldwide. As a professional partner, allmineral provides system solutions tailored to the individual requirements of its customers. The application of intelligent technology and the proven expertise of its people are a guarantee of the best possible concept, professional project management and smooth operation.

allmineral plants and installations are used in Europe, India, Australia, North and South America, and South Africa. More than 750 allmineral installations for dry and wet processing are currently operating reliably and efficiently around the globe.

Image: The new installation shortly before commissioning. Photo: courtesy of allmineral.