Best-in-class design means, in particular, to care about the process water loop by developing solutions ensuring (1) the use of minimum water amount per ton of material treated, and (2) the maximizing of the process water recovery.

It is for this purpose that, leveraging its historical experience in the valorizing of technical clay material, @AKW worked on the design of unique thickening solutions, that integrate clear differentiation edges compared to the solutions commonly made available in the market:

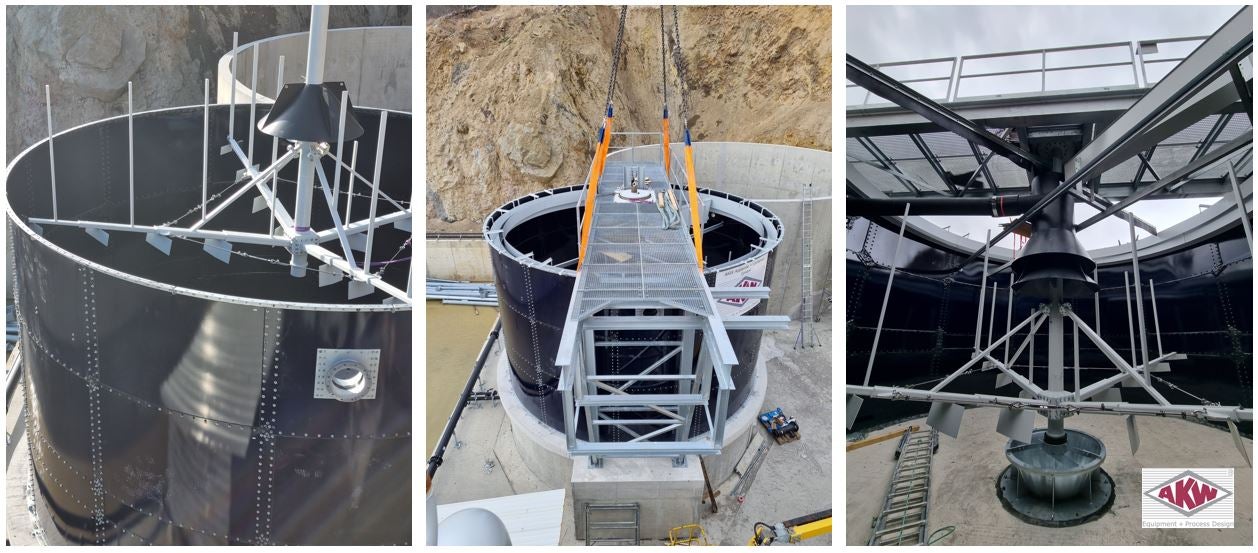

- Specially designed sludge deaeration tank upfront the feeding into the thickener: for better sludge sedimentation results

- Higher tank walls, to generate higher hydraulic pressure on the sludge layer: for better sludge storage capacity handling

- Up to 4 arms equipped with systems of multiple racks/shovels and vertical tubes to de-aerate the sludge bed: for maximum thickening of the sludge bed

- Central feeding by the means of a proprietary bell design positioned below the water level: for a homogenous suspension distribution, and an efficient post-mixing of flocculant

- Smart positioning of the sludge discharge pump, allowing the use of a short sludge discharge pipe: to prevent blocking / clogging

- Thickener bridge mounted over the whole tank diameter: for better access during maintenance operations

- Several additional options available: because the customizing of our solutions is what prevails!

As a result of these unique design features our #thickeners, type AKA-SET, provide our customers with …

- An improved sludge sedimentation ability

- A reduced amount of flocculant used

- A higher solid content in the sludge output

- A smaller overall thickener footprint

- An overall higher water recovery

For more questions on our wide range of thickeners, do not hesitate to contact us.