Application Overview

Conveyor belts transport various bulk materials, including different ores and soil, over long distances to loading silos and other processing areas. To monitor material volume dynamically, it is crucial to implement measurement systems along the conveyor routes. These systems ensure precise control over the extracted material, directly influencing the company’s profitability. The challenging environmental conditions in mining present a significant obstacle for sensor solutions.

Objective

The primary goal is to measure the volume of materials on conveyor belts without physical contact. The ideal device must provide reliable measurements with minimal maintenance compared to traditional systems. Key requirements include a measurement range exceeding five meters, software filters to mitigate environmental effects on data, and the ability to detect lens contamination. Communication with an industrial PC via an Ethernet switch would enable operation with various controllers.

Proposed Solution

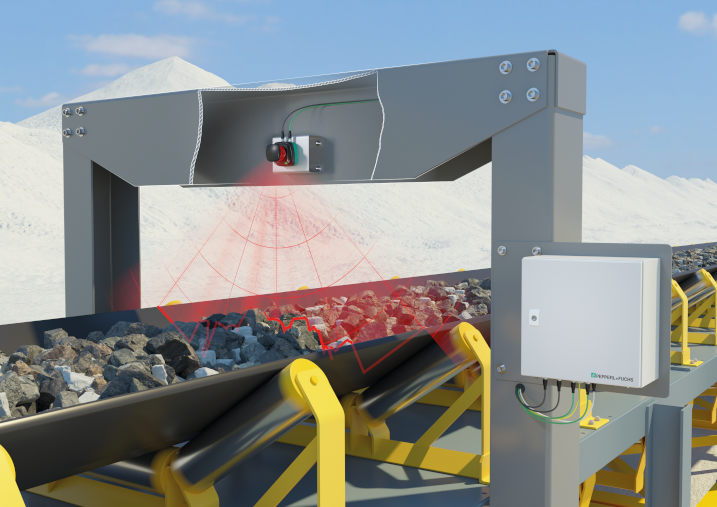

The Volume3D volume acquisition system is designed to meet these needs, consisting of the R2000 2-D LiDAR sensor, a multiscan evaluation unit (MSEU), the ENI58IL incremental rotary encoder, and all necessary connection cables. Positioned on a gantry above the conveyor belt, the R2000 sensor measures material volume without contact. The ENI58IL encoder accurately captures conveyor speed and direction, while the MSEU processes sensor data and transmits volumetric scan data to other controllers to determine flow rates. Additionally, it provides maximum and mean height outputs of the loaded materials.

Key Features of the R2000 2-D LiDAR Sensor:

- Easy installation above conveyor belts

- High angular resolution for precise monitoring of wide belts over 5 meters

- Integrated lens contamination monitor (LCM)

- Pulse Ranging Technology (PRT) for accurate measurements

- Angular resolution of 0.042° and scan rate up to 50 Hz

Key Features of the ENI58IL Incremental Rotary Encoder:

- BlueBeam technology for high measurement quality

- Robust interlocked bearings for high load resistance

- Special EMC circuit protection

- Rotational speeds up to 12,000 rpm

- High shock and vibration resistance

- Blue emitter LED

Key Features of the Multiscan Evaluation Unit (MSEU):

- Robust IP66 housing with integrated industrial PC

- User-friendly data output

- Intuitive Windows software for commissioning and monitoring

- Simple three-step commissioning: installation, configuration, and initialization

- Flexible software platform for application-specific adaptations

Advantages

The Volume3D volume acquisition system is exceptionally efficient, with minimal installation effort and fast commissioning, making it a cost-effective solution for conveyor technology. The noncontact design reduces maintenance costs and prevents unexpected downtimes. The R2000 LiDAR sensor delivers maximum precision with its high angular resolution and rapid scan rate. The intelligent software within the MSEU filters invalid scan points, ensuring accurate measurement results.

During operation, the Volume3D system outputs volume in cubic meters, flow rate in cubic meters per second, height profile across the belt’s width, and dimensions for separated and aligned objects. It also allows the creation of measurement filters and provides data on lens contamination for timely maintenance.

Summary

The Volume3D volume acquisition system offers a precise, reliable, and cost-effective solution for dynamic volume measurement on conveyor belts in mining operations. It combines advanced sensor technology with intelligent data processing to deliver accurate, real-time volume measurements.

High-precision measurements: Achieves dynamic and accurate volume measurements with a single LiDAR sensor.

- Robust and reliable: Designed to withstand harsh mining conditions.

- Cost-effective: Minimal installation and maintenance effort.

This system enhances operational efficiency and material management, crucial for maximizing productivity and profitability in the mining industry.