Watson-Marlow are world leaders in peristaltic pump manufacture for mining, chemical and other industries. Peristaltic pumps handle abrasive, viscous and aggressive liquids. Lime slurry for pH control, acids, corrosive cyanide for gold recovery, grout, thickener underflow – Watson-Marlow pumps handle them all, at up to 80m3/h and 16bar (230psi). Shear-sensitive polymers for flocculation are pumped without degradation.

Peristaltic pumps have no valves, seals or glands to leak, clog or replace. The pumped fluid does not touch the pump itself – it is in contact only with a high-pressure, flexible hose. Maintenance is confined to a periodic hose change, which takes minutes. Peristaltic pumps can run dry, reverse their direction of flow, and are self-priming.

Peristaltic pumps

Mining industries handle corrosive, toxic media with high specific gravities, which cause problems for other pump types. Valves clog, diaphragms perish, rotors corrode.

Peristaltic pumps – hose pumps, as they are called in larger sizes – operate on the positive-displacement principle of our digestive system. Within the pump housing, rollers compress the hose against a semi-circular track – like flattening a garden hose between finger and thumb. The pressure point moves along the hose, pushing the tube’s contents before it. Behind the pressure point, the hose resumes its shape, sucking in more fluid. Solids – even bulky ones – are carried through the pump harmlessly.

World leaders in high-pressure hose pumping

The key to the process is the hose. For high-pressure applications, our hose has a composite construction formulated to withstand abrasion and chemical attack. The inner core is manufactured from soft material, cushioning any solids caught in the compression phase of peristaltic motion, and leaving shear-sensitive flocculants undamaged. The outer covering is hard rubber, reinforced with braided nylon.

The pumps are available with drives suitable for high-pressure washdown, TEFC and explosive environments.

Bredel hose pump – the future of high-pressure hose pumping

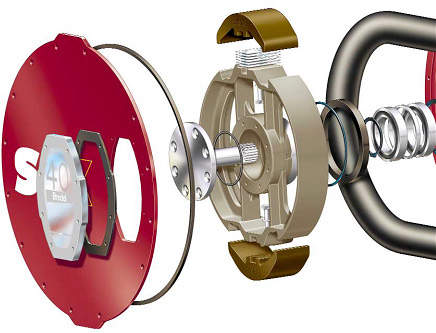

The force needed to compress the hose in a large hose pump, up to 100mm in diameter, is substantial. Bredel models – state-of-the-art leaders among high-pressure peristaltic pumps – feature a patented, direct-coupled design: a large, twin-bearing hub supports the rotor – placing no stress on gearbox bearings. No baseplate is needed, and the footprint is minimal.

Widely used for handling abrasive slurries, pumping silica suspensions up to 70% solid by weight with no settling out, and transferring tailings including particles typically 5mm in diameter, Bredel hose pumps help produce gold, platinum, vanadium, nickel, coal, copper, kaolin, diamond, trona, uranium … the list goes on.

Watson-Marlow pumping solutions

Copper tailings – slurry is very abrasive. Centrifugal pumps with soft packing shaft seals had to be water-flushed to limit wear on the shaft sleeve. Fine until winter froze the water. Solution: a Bredel 100, with no seals to wear out. Tailings could be continuously pumped at higher concentrations, doubling plant efficiency. Downtime: a few minutes every 2,000 hours to change the hose.

Natural kaolin – abrasive sludge with high specific gravity. Solution: a Bredel 40, 80 or 100, pumping slowly, at high volumes, without hardening the sludge.

Acid slurry platinum waste – pumped with low pulsation from settling tanks to cyclone for separation. Solution: a Watson-Marlow 700 pump with acid-resistant Marprene tubing and a four-roller rotor for minimal pulsation.

Ammonia metavanadate slurry – delivery lines blocked when centrifugal or eccentric screw pumps were used. Solution: a Bredel 40 with no valves or obstructions to clog.

See also: