FELUWA Pumpen has at its base in excess of 100 years’ company history and is successfully focusing on the development and fabrication of pumps for the mining industry.

Evolution of the MULTISAFE hose diaphragm process pump

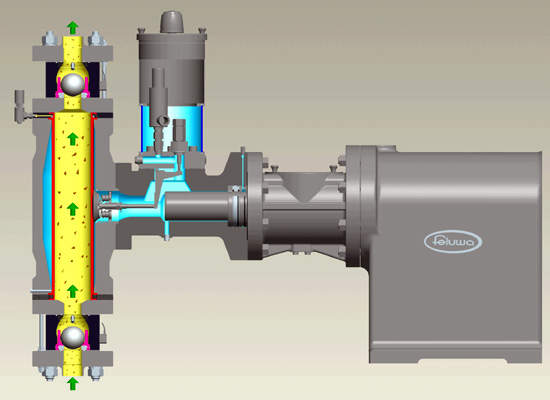

With the development of its hose diaphragm piston pump more than 30 years ago, FELUWA has been countering the disadvantages of traditional diaphragm and diaphragm piston pumps. It provides for the hermetic separation of conveyed fluid from the hydraulic system by means of a combination of a flat diaphragm with an additional hose diaphragm. In the process, the conveyed fluid is led in a linear flow path through the hose diaphragm and is in contact solely with the inside of the hose diaphragm and check valves.

Although hose diaphragm piston pumps already represent significant advantages over diaphragm pumps with several thousand units being well proven, consistent further development has been pursued with the MULTISAFE double hose-diaphragm pump.

The MULTISAFE is a hermetically sealed, leak-proof, oscillating displacement pump with double sealing of the fluid chamber from the environment. The flat diaphragm is completely abandoned.

Bionics in pump design

The development of the MULTISAFE hose diaphragm pump has essentially mimicked the perfect mechanism of the human heart by utilizing the principle of contraction and release of veins via variable speed.

The MULTISAFE hose diaphragm pump is based on the same well proven working principle: at the heart of this pump are two hose-diaphragms, although the pump needs only one to operate. These are arranged one inside the other and fully enclose the conveyed fluid. In step with the piston stroke, they are subject to pulsating action, comparable with that of a human vein, which pumps the fluid through the pump body in a linear flow path. Even in the event of one of the hose diaphragms failing, the slurry will not come into contact with the pump casing. Pump operation can still be continued until the next planned shut-down of the unit. Since the conveyed fluid, even in such a scenario, will not come into contact with the casing, the necessity of expensive special materials, chemically compatible with the fluid can be avoided.

Comparison with traditional designs

With diaphragm piston pumps, the conveyed fluid and hydraulic drive system are separated by a flat diaphragm. The conveyed fluid is both in contact with the diaphragm and the pump casing. In the event of damage (diaphragm failure) conveyed fluid, that is in many cases of an aggressive nature, is introduced into the hydraulic control area and causes considerable financial expense, as well as pump downtime to clean and repair.

Double diaphragm pumps have been developed with two hydraulically coupled flat diaphragms to prevent such damage. The design and working principle is identical to that of the diaphragm piston pump. However, with double diaphragm pumps the conveyed fluid is in direct contact with both the flat diaphragm and the pump casing. As a result of this construction, the casing must be resistant to the conveyed fluid. Moreover, solids may settle around the diaphragm clamping mechanism causing damage due to abrasion that ensures shorter diaphragm life.

Diagnostic systems

For early detection of faults and with the objective of ensuring maximum availability, FELUWA supports the redundant nature of MULTISAFE double hose-diaphragm pumps by means of an overall diagnostic system.

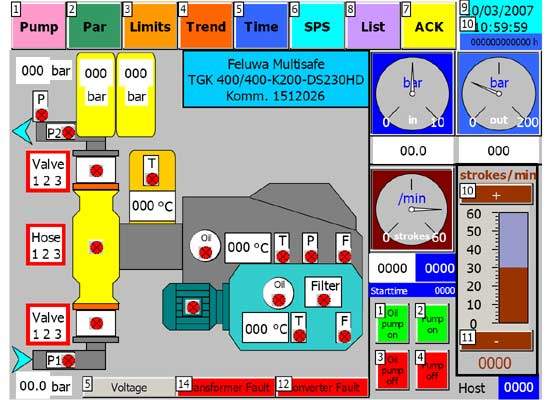

Touch panels, which are integrated into the control cabinet, give the pump a transparent character and provide the operator with information on current operating parameters and the condition of fundamental parts.

The link to local process control is made by means of bus systems, whereby PROFIBUS (Process Field Bus) provides best conditions for the communication and control of system frequency converters, PLC, touch panels and the FVPMS (FELUWA Valve Performance Monitoring System) with Sitrans DA, being supplied by FELUWA.

The pump can either be controlled via the frequency converter panel, the FELUWA touch panel of the local control or via the client’s DCS system with setpoint setting (via analogue input 4mA to 20mA).

The touch panel provides information on the following operating conditions:

- Check valves (via FVPMS)

- Primary and secondary hose-diaphragms

- Suction and discharge pressure

- Hydraulic temperature

- Stroke rate

- Pre-compression of bladder-type accumulators of pulsation dampeners

- Oil lube systems of the crank drive and intermediate gear (including temperature, pressure and flow)

- Motor (including measurement of torque, absorbed power and FELUWA pump speed)

- Transformer and frequency converter

Tele service via internet allows for immediate online corrective action and, in many cases, saves the need for service on site.

MULTISAFE hose-diaphragm pumps are available for flow rates of 600m³/h and pressures of up to 320bar.