Custom Mining Products designs, develops and manufactures equipment for underground mining and tunnelling applications.

The company has been working on a number of new projects with mine management and employees to develop custom-built equipment to improve safety and productivity.

All products are designed and manufactured in Australia, and these designs have been registered and patented with the aim of global expansion.

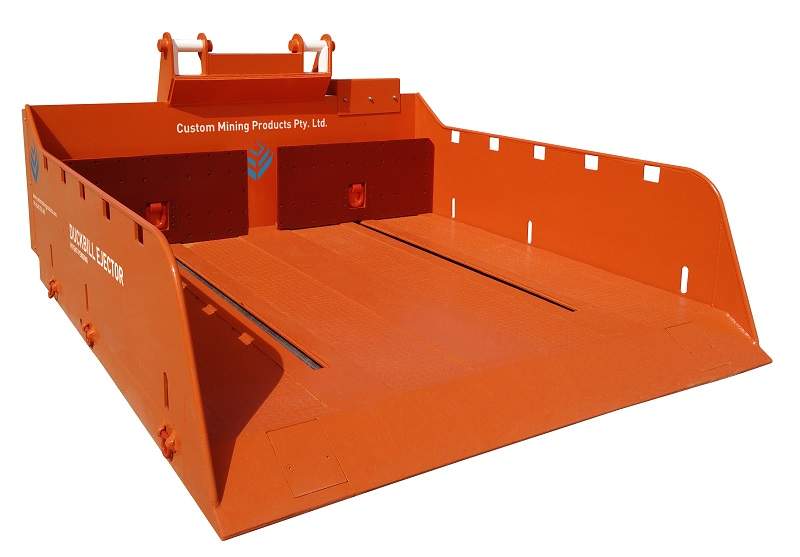

QDS Pallet Handling System (Duckbill Ejector) for reduced manual handling and product damage in underground mining environments

The QDS Duckbill Ejector is a safe solution for carrying, ejecting and retrieving palletised products and bulky loads on LHD underground loader. Hydraulically actuated pusher plates allow an operator to unload pallets all at once or one at a time, in different locations in a controlled manner. Pallets and equipment can also be pulled back on.

The ejector has been in development for five years, and has been tested at various mine sites for more than 18 months. It is now in use at major mine sites in New South Wales and Queensland.

It won the excellence in mine safety, occupational health and safety (OH&S) award at the 2015 mining and prospecting awards.

Drill water capture systems

Up to 1,800l/h of water is used in the drilling process to install roof support, such as cable bolts in underground mining and tunnelling.

Spent drill water can cause damage to roadways, and create slippery and hazardous conditions for mine workers.

Dry drilling and mist drilling have been used in the past (compressed air and water), but proved to be unsuccessful, with soft and muddy conditions constantly causing drill bits to block-up.

The drill water capture system was created as a reliable alternative to dry and mist drilling. Designed to capture up to 1,800l/h, the drill water capture system collects and separates the spent drill water from the fines. Captured water is delivered directly to the pump while fine pieces of coal and rock are discharged onto the ground.

Up to 95% of the water is captured, has no moving parts, and weighs just over 10kg.

The drill water capture system has been more than three years in development, and is in use at major mine sites in New South Wales and Queensland. It also won the mining innovation award at the 2015 mining and prospecting awards.

QDS Recovery Pod for safe recovery of underground equipment

The QDS Recovery Pod is a safe and efficient means of carrying and recovering loads in an underground mine. It is designed to carry 7,000kg and is fitted with a hydraulically operated winch with 6,000kg of pulling power.

Unlike other QDS Winches, loads can be pulled on for transport. Rather than having to pull the load and the winch needing to be taken off, with QDS Bucket being used to try and scoop up the load.

Other features include:

- 6,000kg of pulling power (Brevini winch). Reversible for controlled unloading

- Tapered leading edge with 50m of 16mm Lankoforce winch rope

- Ideal for longwall moves, loading damaged equipment, pulling conveyor belt and retrieving loads

Custom-built underground intensifier pumps

After working with Enerpac, Custom Mining Products now offers a custom-built intensifier pump to speed up the tensioning process in underground mining and tunnelling.

All exposed aluminium components have been replaced with alternative materials. The traditional foot pedal has been replaced with a simple directional control lever on manual pumps, and a pendant control for the pendant pump.

Features of the pump include:

- Up to six times faster than other air-operated tensioning equipment

- Two-speed operation reduces cycle times for improved productivity

- Tensions cable bolts to 20t-30t with as low as 60psi air-pressure

- Incorporates proven technology of Enerpac ZA4 pumps, which is ATEX 95 certified for use in potentially explosive atmospheres

Megabolt and component installation dolly

The new megabolt dolly has been developed by custom mining products to facilitate the installation of mega bolts and eliminates the need for ladders during the megabolt installation process.

The new dolly installs the megabolt, the plate, the barrel, and the wedge in a single operation. Once the bolt has been installed and flushed, the dolly removes the plastic cap, leaving the megabolt ready for tensioning. Features include:

- Eliminates the use of ladders

- Eliminates ‘short bolts’ with the tails of each bolt left at the correct length for tensioning

- Uses the power of the machine to push the installed bolt and plate hard up to the roof

- Speeds-up production by eliminating the need to plate the bolts at another time

- Reduces tensioning times, with most bolts requiring a single bite with the tensioner head