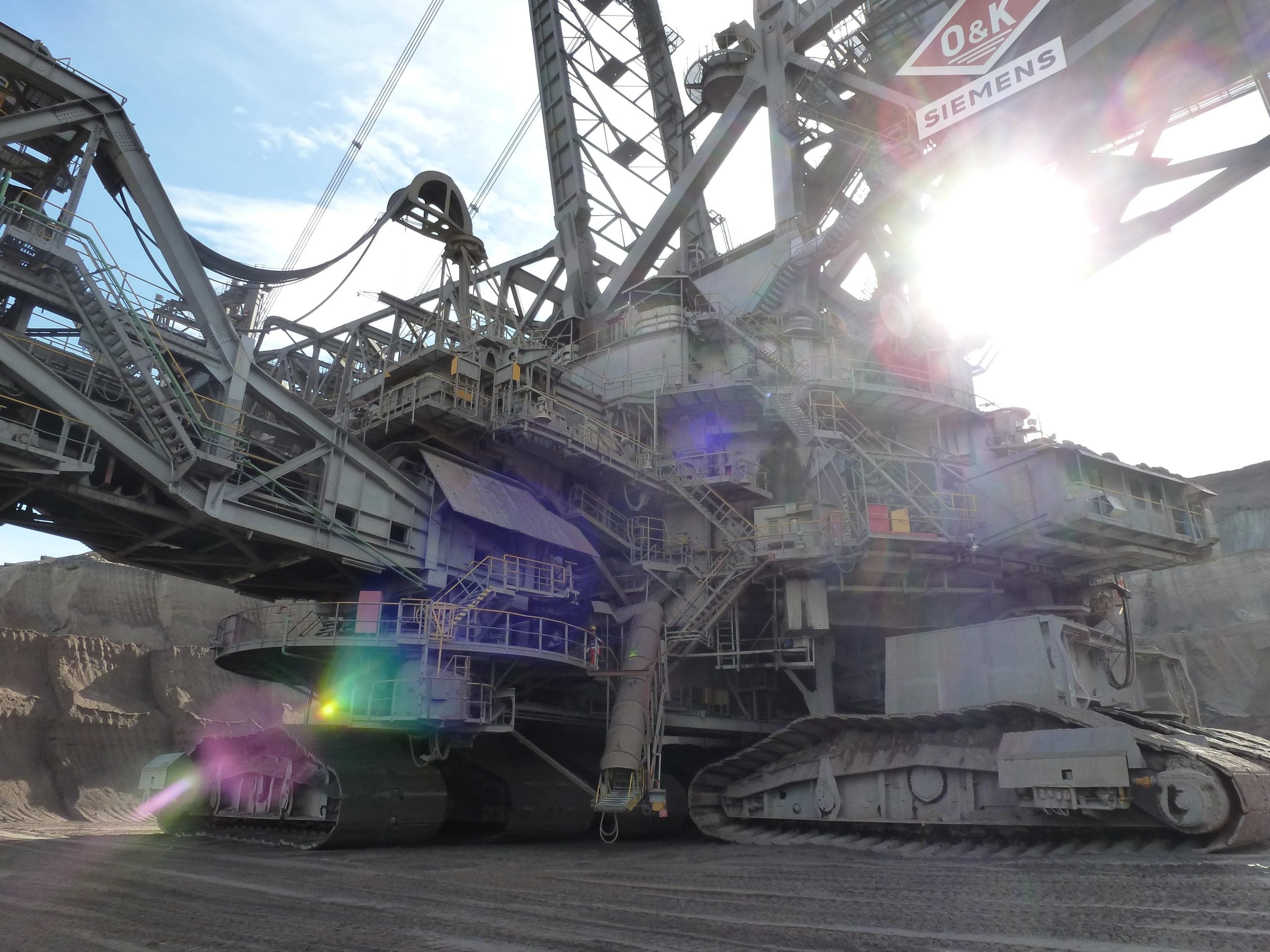

Malmedie Antriebstechnik is an industry-leading company specialising in mechanical drive train solutions for heavy duty industrial markets, such as steel, mining, port and marine.

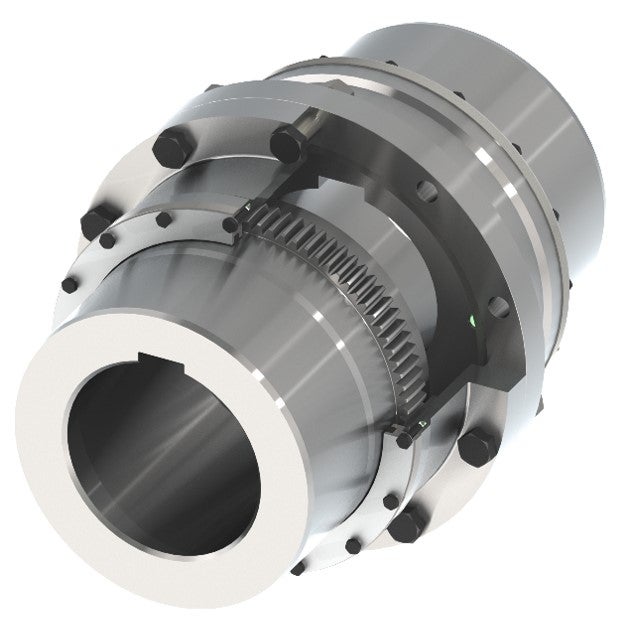

The company focusses on gear couplings and gear spindles, safety couplings (mechanical torque limiters without consumables), drum couplings, and special solutions where high torque transmission is essential and the work environment is rough.

Malmedie products are used in the most demanding applications where system-availability and reliability are mission-critical. We rely on our decades of experience and deep expertise in coupling design and production. This allows us to constantly innovate our product portfolio and to offer our customers tailor-made and purpose-built solutions.

We develop products which support our customers needs of reduced energy consumption and increased automation. All of our products are made in Germany.

Due to our high manufacturing depth, we are able to fast-track production of components and to offer expedited air shipment. In addition, we offer service support around the globe. We are also able to help with the choice of the right coupling or with any question regarding maintenance.

Safety couplings for a fast mechanical connection

Malmedie manufactures durable and reliable safety couplings for mining applications. These torque limiters are integrated into the drivetrains of heavy duty powertrains. Here, they prevent excessive wear and ultimately equipment failure by releasing the connection when an over torque is reached.

Importantly, our safety couplings do so purely mechanically and ultra-fast. The reset of the connection can be done within minutes manually, without the need of hydraulics or electric circuitry, without consumables, without the need of special tools or knowledge. Automated solutions are available as well.

Malmedie also offers safety couplings with strongly reduced inertia (about 50%) and reduced weight. This saves energy, especially in applications with frequent accelerations and decelerations.

Acceleration and deceleration of inertia are proportional to power consumption in drivetrains. Reducing inertia of the coupling means that all components in the powertrain will see smaller mechanical loads. Reducing the “mechanical footprint” of the coupling also contributes to choose other smaller components, saving initial investment cost and resulting in additional inertia-related energy savings.

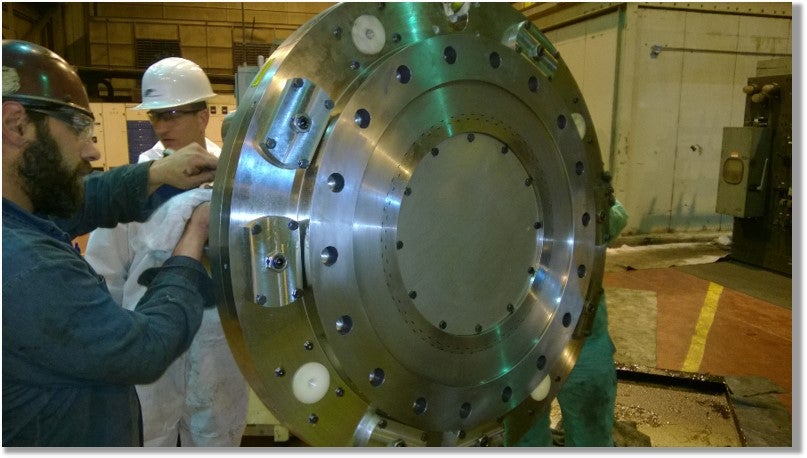

Gear couplings and gear spindles for demanding environments

Malmedie produces gear couplings and gear spindles for high-torque, heavy-duty environments of exceptional quality. Over the years, the company has accumulated significant know-how on designs which promote low wear, fatigue-resistance and maintenance friendliness, resulting in long lifetimes of our products and reduced lifetime cost.

Gear couplings and gear spindles allow to transmit rotational movement, high speed and high torques while compensating for axial, angular and radial misalignment. Our products are made from high-grade material, different surface treatments are available.

Many of our products can be used to retrofit legacy designs. With our SNX series, we offer solutions to facilitate easy access to drivetrain components such as break or clutch systems. Typically, the integration of such components allows to reduce access time to a fraction.

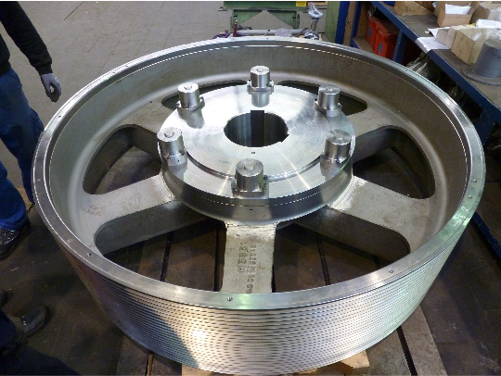

Barrel-roller type couplings for the transmission of radial forces

Malmedie is the inventor of the barrel roller type coupling and continues to set the standard in this technology. Generations of students in Germany knew the barrel roller type coupling as Malmedie coupling. A barrel roller type coupling is a flexible coupling for rigid torque transmission, which allows to transmit significant radial forces.

It permits axial and angular movement. Instead of interlocking gears, this coupling type uses barrels which transmit loads between coupling halves. Gear couplings are not designed for the transmission of radial forces, whereas barrel-roller type couplings were invented for this very purpose.

Barrel-roller type couplings are often called drum couplings. Whereas the name barrel-roller type focuses on the design of the coupling, the name drum coupling focusses on the most common application where it is found. The barrel-roller type coupling is a standard component in heavy duty hoisting designs (such as cranes), typically directly mounted to the rope drum (hence the name).

Tailor-made solutions for the mining industry

We tailor our products to the needs of our customers. Hub length, choice of bore diameter and a wide variety of connection designs (i.e. single or multiple keyways, gear connection, shrink-fit) are standard for us. In many cases, we are able to cope with spatial constraints by adjusting existing designs.

As a technology leader, we believe in being close to our customers and users. There is a good chance that we have seen challenges in the past and are able to offer a proven solution. If you are curious to get to know us better, or in case you have a question about our products and services, reach out to us!