Backstops provide critical safety, control, and protection for the inclined sections of overland and underground conveyors. In this blog, we take a look at how conveyor backstops work and why they’re important for protecting staff and equipment plus ensuring your project stays on track.

Read on to learn more about how backstops help to stop things from going downhill during conveyor stoppages.

THE IMPORTANCE OF INCLINED CONVEYOR BACKSTOPS

Imagine driving a car without a brake. What would happen if your vehicle suddenly lost power while going up a steep hill?

Backstops perform a similar function for industrial-scale inclined conveyors that transport raw materials out of mines and over hills and ridges. Without backstops, a sudden stoppage or mechanical or power failure could see hundreds of feet of inclined conveyor belt reversing directions as gravity takes over.

Without protection, a failure like this could send a belt loaded with hundreds of tons of raw material sliding downhill with little or no control.

HOW DO BACKSTOPS WORK?

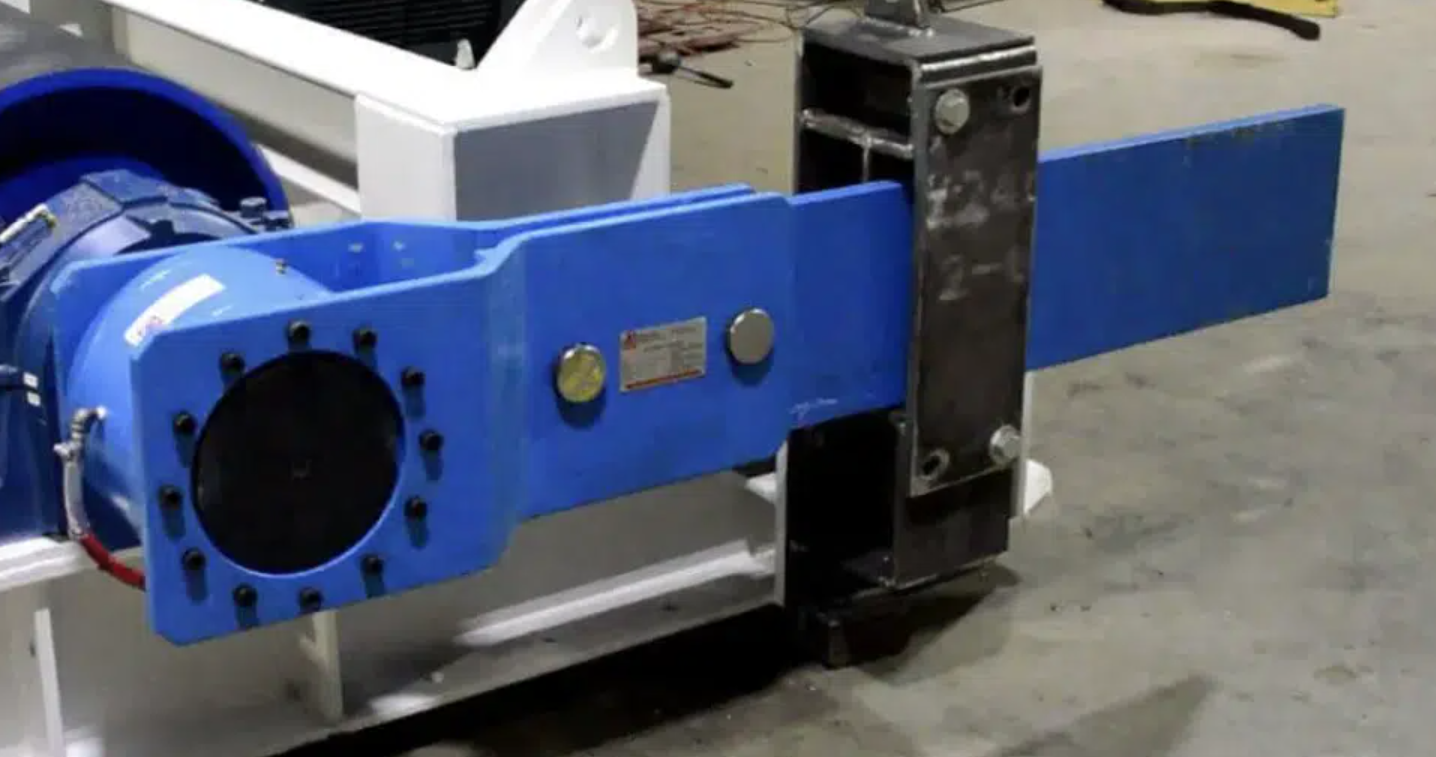

Backstops are mechanical devices mounted on conveyors that engage automatically whenever a conveyor belt tries to move backward, locking it in place and preventing dangerous rollbacks.

To do this, many backstop designs use a ratchet-and-pawl mechanism. When the conveyor belt moves forward, the ratchet turns freely but if the belt attempts to move backward, the pawl engages with the ratchet teeth, locking the belt and preventing any reverse movement.

Other designs employ a more complex differential handbrake and overrunning clutch designs that provide more fine-tuned protection but also require specialist adjustment and maintenance.

Overland conveyor systems typically employ at least one backstop, although it is often wise to install several to provide redundant protection on parts of the conveyor with a high potential for runaway motion if the power fails.

5 CONVEYOR BACKSTOP BENEFITS

By providing control and stability when inclined conveyors stop unexpectedly, backstops help keep your production on-line — literally. Let’s take a look at some major inclined conveyor backstop benefits.

1. PROTECTING YOUR STAFF

Safety is always Job Number 1 and backstops are an essential piece of safety gear on any inclined conveyor section. A functioning backstop means workers will never need to try and restart a conveyor while the belt is still in motion, which is a very dangerous situation.

When triggered, backstops also prevent potentially uncontrolled slides of rock or aggregate back towards areas where your staff might be and minimize the chance that employees will be injured by slumping materials spilling off a slipping conveyor belt.

Indirectly, backstops help to protect staff by minimizing the need to clean up spills in hard-to-access areas or to move material off sections of the belt. They also help to prevent damage to the belt that could eventually lead to a dangerous, catastrophic belt failure.

2. PROTECTING YOUR PRODUCT

Properly designed and installed backstops also prevent damage to or loss of the product you are moving. Even a minor slip can lead to a large volume of valuable material being spilled, blown, or shaken off the line.

Larger spills can be even more costly and difficult to remediate. Damp coal immediately loses value and semi-processed products may be difficult or impossible to retrieve. You might also face environmental costs and sanctions if wetlands or other sensitive environments are contaminated by a spill.

Backstops help keep material in place if your conveyor goes down, ready to resume operation once the stoppage is over.

3. PROTECT YOUR CONVEYOR

When your powered inclined belt stops and gravity takes over, backstops act directly to help prevent damage to the conveyor structure, idlers, and other components from overloading or excessive force generated during slippage.

Backstops protect your conveyor equipment indirectly, too. Belts that reverse direction sharply or frequently—especially when heavily loaded—create more wear and tear on the belt fabric. By limiting this movement, backstops help to extend the lifespan of your product-specific belt.

Uncontrolled movement can also lead to belt misalignment in an inclined conveyor. Misaligned belts can rub against idlers, frames, and pulleys and lead to damage and premature wear to the structure of your conveyor itself.

4. REDUCING MAINTENANCE

Sudden stoppages place a lot of strain on all conveyors. The ability of backstops to limit wear and tear and damage to conveyor components during stoppages also delivers benefits for maintaining conveyor systems.

By reducing strain on belts and wear and tear on idlers, motors, and the conveyor structure itself, backstops act indirectly to reduce the amount of maintenance these components need over time and contribute to longer lifespans for consumable parts.

Properly installed and maintained backstops can help reduce maintenance, labor, and parts replacement costs throughout the life of your conveyor.

5. PROTECTING YOUR CAPITAL INVESTMENT

Whether underground or overland, a conveyor system represents a major capital investment for ventures of any size. Efficient, adequate backstop protection helps to protect your return on investment by extending the lifespan of your equipment and reducing the cost of ownership by reducing maintenance and repair costs.

Backstops also benefit your investment indirectly by helping to protect your staff from injury, shielding you from compensation claims and keeping valuable workers on the job. They may also help prevent or limit the environmental impact of an unplanned stoppage or accident that could damage your business’ brand and relationships.

Perhaps most importantly, however, backstops protect you by keeping production on track during and after unexpected or accidental shutdowns. You’ll suffer fewer losses and resume normal operations earlier. Seen this way, backstops deliver value far above the cost of installing, inspecting, and maintaining this equipment.

WEST RIVER CONVEYORS: YOUR TRUSTED BACKSTOP PARTNER

Backstops protect more than just your conveyor belt. But to deliver full value this crucial piece of safety equipment needs to be properly installed, inspected, and maintained. As a leading supplier of conveyor equipment and parts worldwide, West River Conveyors offers unrivaled experience in supplying and supporting your backstop requirements.

Our experienced staff will work with you to assess your current or new backstop needs, including critical protection on vulnerable uphill sections and redundant capacity to protect your investment in the event of overloading or catastrophic equipment failure.

We aim to be your partner, not just a supplier. That means we’re committed to meeting your needs both today and into the future. We’re ready to reassess your backstop installation if your conveying needs change, rightsizing to your production targets and efficiency goals.

And, as an end-to-end conveyor designer, builder, and support specialist, we have the knowledge, experience, and quality parts needed to support your conveyor equipment over the long haul.

Contact us today to find out more, or click below to learn about our range of leading brand backstop products.