RBL-REI is a leading figure in the handling industry and has been producing installations for the mining sector for almost a century. The company’s installations include the unloading, transfer, storage, reclaiming and loading of all solid bulk products, such as mine products, limestone, aggregate, coal, cereals, cement, fertiliser and clinkers.

The French business produces belt and overland conveyors, stackers, reclaimers, scraper and apron feeders, pan conveyors, mobile feeders, hoppers, train loaders, ship loaders and more to the mining industry.

Certified manufacturer of conveyors, feeders and hoppers

RBL-REI manufactures its equipment in its own ISO 9001 certified workshops. RBL-REI China, a subsidiary of RBL-REI, was created in 2005 and is based in Shanghai, fabricating and installing Curvoduc™ overland curved conveyors.

Boasting its own highly-experienced supervision and erection teams, RBL-REI is well equipped to meet its clients’ needs. For assembly abroad, supervisors are available for assemblies in every corner of the world, with the company holding the UIC agreement.

Overland conveyors

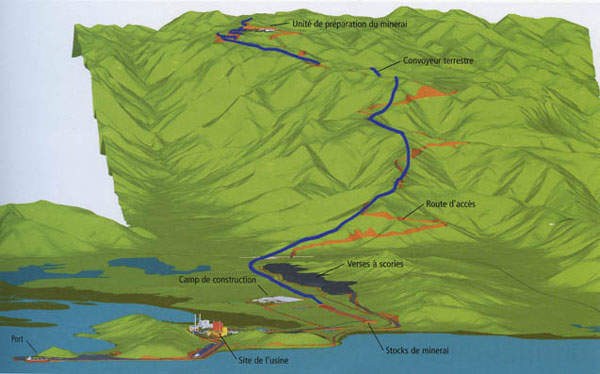

For the last 50 years, RBL-REI has been continuing to expand with the development of modern, customised equipment, such as mine conveyors and long-length ‘overland’ conveyors. RBL-REI has set major benchmarks in the field of overland curved conveyors, with its Curvoduc™ boasting 17km capability, a minimum radius of 250m and rates of up to 20,000t/hr.

RBL-REI was commissioned to deliver two 40km lines of conveyor belt in Fengkai (China). These two parallel lines, each at 2,500t/hr, will supply one of the world’s largest cement works with 30,000t of cement a day. Each line includes three overland conveyors (11km, 12km and 17km), powered in total by 19 750kW driving units, with a belt speed of 5m/s. Curved conveyors (Curvoduc™ or overland) are suitable for crossing and passing over hilly terrain, as well as roads, rivers and paddy fields.

The first line of this incomparable equipment was successfully commissioned in four weeks, once the finishing touches were put on the first three conveyors after an assembly time of just eight months. Work on the second line is expected to take even less time to complete than the first.

Engineering, research and development of conveyors

Curvoduc™ / overland conveyors are characterised by extremely complex sizing and calculation stages. The results obtained determine the correct operation of the equipment in all of the operating stages encountered during its use.

More than 60 years’ worth of feedback has fine-tuned our software programmes to ensure more realistic modelling. The renowned reliability of our Curvoduc™ stems largely from improvements suggested in customer feedback. From the results obtained, RBL-REI determines a risk-free belt alignment. Regardless of the number of bends and the convex and concave shape of the conveyor belt, this calculation means that the very best design can be chosen to ensure the stable performance of the belt in all operating stages.

Additionally, RBL-REI manages all the electrical control aspects of its Curvoduc™ conveyors. These systems, specifically designed for the Curvoduc™, facilitate monitoring in every stage of the Curvoduc’s operation.

Overland curved conveyors

The Curvoduc™ range also incorporates highly economical and technical solutions, such as a 6.8km Curvoduc™ created in China, connecting a port to a nearby cement works. The Curvoduc™ supplies the port with clinker at 1,200t/hr (upper strand) and simultaneously supplies the cement works with coal at 400t/hr (lower strand). It is fitted with three 500kW driving units and its line comprises two 1,000m bends.

Curvoduc™ can also achieve very tight bends, such as a conveyor of 1.1km realised in France which supplies a thermal power plant with coal at 600t/hr from barges in the Moselle river. Thanks to the 250m and 300m radius bends, the ‘S’ shape means that a single conveyor belt can be laid down instead of three straight conveyors. Fitted with 1,200mm of belt, this Curvoduc™, which is over 1km long, crosses a canal and an ash yard.