PHOENIX is the leading manufacturer of high quality conveyor belting for the worldwide mining industry. This covers all kinds of belting for all applications, for use underground or above ground.

PHOENIX provides customised conveyor belts for highly complex applications throughout the world:

- Polyflex: multiply conveyor belts

- Duoflex: two-ply conveyor belts

- Uniflex: solid woven conveyor belts

- Phoenocord: steel cord conveyor belts

- Phoenotec: active protection system

- Phoenopipe: pipe conveyor belts

- PHOENOGUARD PX: continuous conveyor belt monitoring

- Phoenocare: SL – conductor loop, SC – conveyor belt splice monitoring system and T-Transponder

PHOENIX started making conveyor belts 110 years ago in their headquarters in Hamburg, Germany. Today, the Conveyor Belt Group comprises factories in Germany, Hungary, India and China.

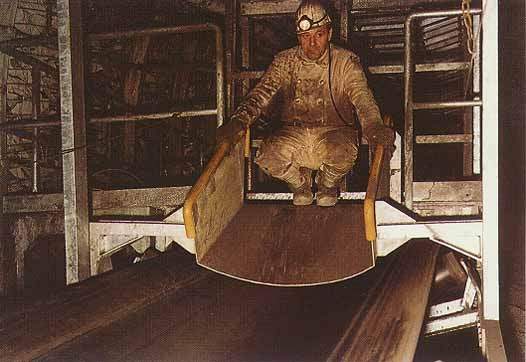

The strongest underground conveyor belt in the world

This super belt is 7.5km (4.7 miles) long, 1,400mm (55in) wide and 35mm (1 3/8in) thick. Tensile strength is 8,200N/mm (47,000piw).

The PHOENOCORD St 7500 has a breaking strength of 8,200N/mm (47,000piw). It conveys 2,000t/h of coal over a lift of 783m (2,600ft) up to the surface and, simultaneously, 1,000t/h of washery refuse back underground.

A main contribution to the excellent performance of this extreme conveyor belt is the unique PHOENOTEC™ active protection system integrated in top and bottom covers. The self-extinguishing PHOENOCORD St 7500 meets the stringent safety requirements for German underground coal mines.

The highest capacity conveyor belts worldwide

These giant PHOENOCORD belts convey up to 40,000t/h of overburden and lignite on the biggest bucket-wheel excavators on Earth. The conveyor belts are 3,200mm (126in) wide and 45mm (1¾in) thick.

The first self-extinguishing steel cord conveyor belts in the world

In 1975 Phoenix supplied this 3,000m (9,842ft) long conveyor belt type St 4000 which was the first one to meet the highest safety requirements for underground applications worldwide (DIN 22129).

The strongest conveyor belt on earth

In 1998 Phoenix supplied a new world record conveyor belt, a 23km (14.5 mile) long PHOENOCORD ST 7800 for the Los Pelambres copper mine in Chile. This conveyor belt breaks any of the existing Phoenix world records. Its tensile strength is 8,500N/mm (48,500piw).

The splice fatigue strength as per DIN 22110 is 4,213N/mm (=54% of minimum belt breaking strength).

During belt operation the belt splices are monitored by the pathbreaking electronic monitoring system PHOENOCARE SC.

The heaviest conveyor belts on earth

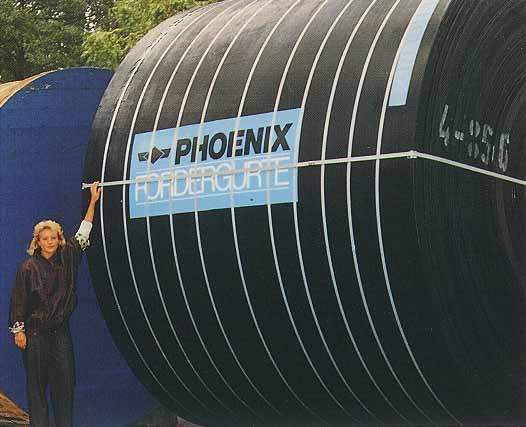

For the highest mine on Earth at an elevation of almost 5,000m (16,000ft). 17,000m (57,000ft) of a PHOENOCORD St 6300 were supplied to the Collahuasi mine complex in the Chilean Andes.

In order to reduce the number of field splices the single lengths were shipped on oval reels, having a weight of 58t. Such large single belt pieces have never been made before.

The reel dimensions are: 5.2m long, 4.3m high and 2.3m wide. Thanks to this special packing method, 415m (1,360ft) of this big St 6300 fit on one roll.

The independent PHOENOGUARD® PX – localises any damage

PHOENIX Conveyor Belt Systems is introducing a revolutionary new development with PHOENOGUARD PX. The autarchical monitoring system continuously measures the current overall condition of the conveyor belt, internally and externally. From notching on the covers to penetration of foreign bodies and damaged steel cords, this unprecedented technology not only records damage but also intervenes automatically in the operation of the system in cases of emergency. If the system identifies damage that could result in breakdown of the conveyor belt, PHOENOGUARD PX immediately shuts the conveyor system down. In the case of minor damage that has no direct impact on the condition of the conveyor belt, the system triggers an alarm. Users can adjust these settings in line with their requirements.

PHOENOGUARD PX uses this method of targeted intervention to prevent serious damage from occurring and dramatically reduce maintenance costs. If users want to get an impression of the overall condition of the conveyor belt, the system is able to provide a comprehensive snapshot image at the click of a mouse.

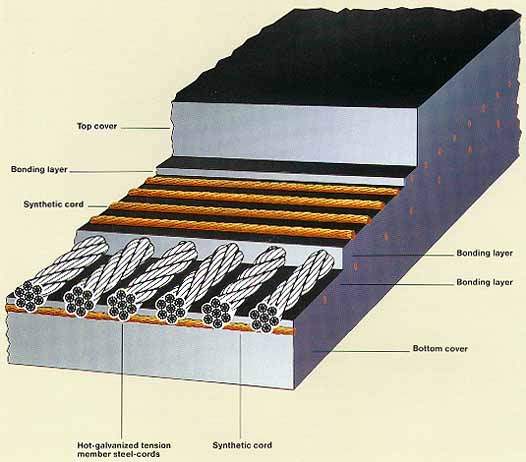

PHOENOTEC™ active impact damage and rip protection system

PHOENOTEC consists of highly elastic high strength synthetic cords, which are arranged at right angles to the longitudinal axis of the belt. Spacing and diameter of the PHOENOTEC cords are determined in dependency on the application. The PHOENOTEC cords are not connected to one another.

PHOENOTEC increases the belt’s resistance to impact and slitting drastically.

About the brochure ‘Design Fundamentals’

This brochure from PHOENIX Conveyor Belt Systems provides comprehensive information on the calculation and design of conveyor belt systems.