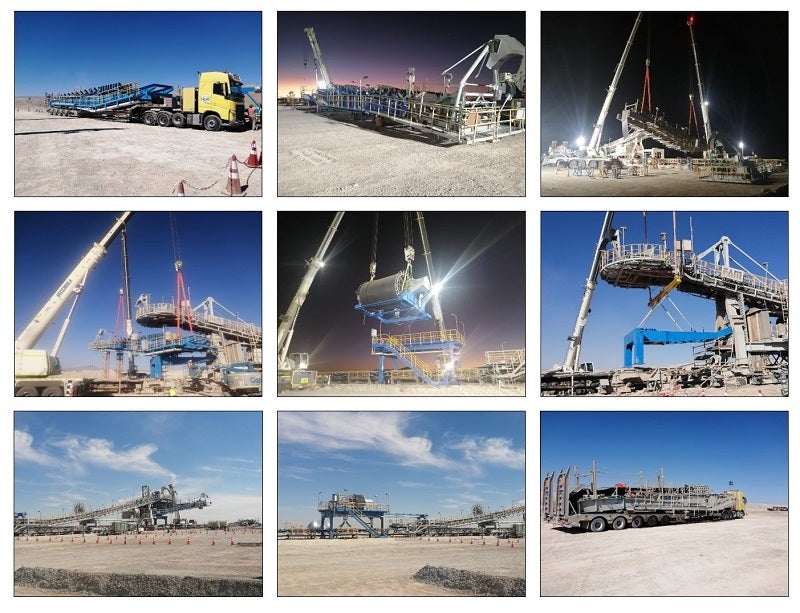

FAM completed extensive reconstruction activities aimed at increasing the performance of the MH014 rail-bound tripper car with a slewing boom in the Ripios section of Minera Spence.

Installation of a new, reinforced discharge boom (including a portal for the lower ring beam), replacement of the ball bearing slewing ring and installation of additional travel drives served to increase the output of the machine from 4,000 to 5,300 t/h of leached copper ore. At the same time, a new cable drum carriage was added to the conveyor line. This enables continuous operation over the entire length (approx. 1.2 km) of the shiftable conveyor CV027 without having to change the feed source for the stacking devices.

The implementation of the construction site took place during a scheduled shutdown of the plant. This project was another example of the excellent cooperation within the FAM Group. The contract (manufacturing, installation and commissioning) was handled by FAM América Latina Ltda., the project engineering was completed by FAM GmbH. The quality of the work, adherence to deadlines and high safety standards during the project implementation were highly acknowledged by the customer.