Due to the Evolving Needs of their Customers, CST Have Expanded the Capabilities of the IntelliRoll

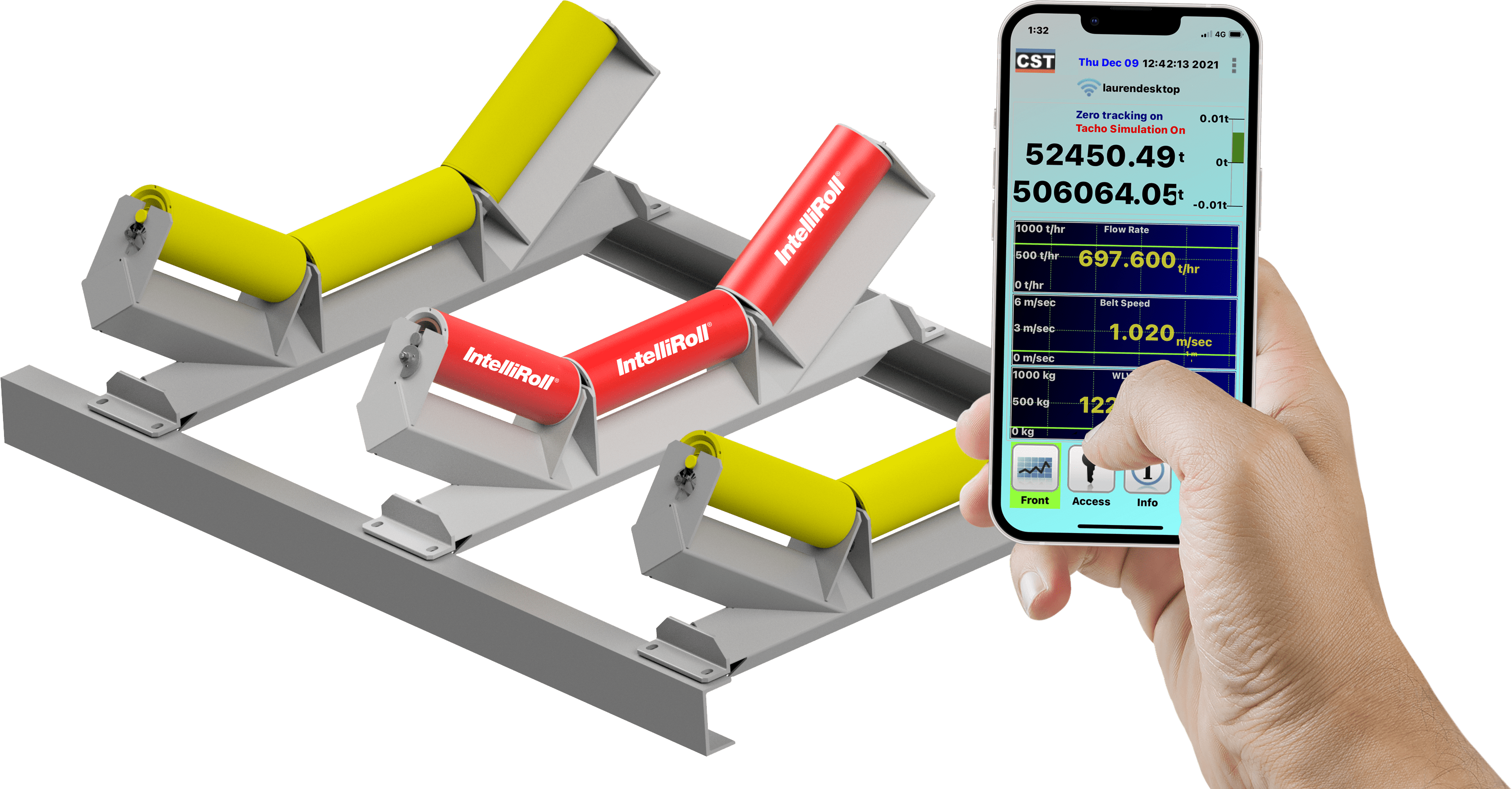

Due to the evolving needs of their customers, CST have expanded the capabilities of the IntelliRoll. At the forefront of belt weigher technology, CST is winning awards with its IntelliRoll. The IntelliRoll has many advanced features like connectivity to existing PLC via Wifi network, or directly to a smart device using Bluetooth or Wifi.

There are other capabilities such as storing data on board which can then be logged later. Multiple IntelliRolls can also be linked together to increase overall accuracy of the weigh data. The IntelliRoll can be fitted to mobile or remote plants without power cabling.

CST have now advanced the applications of IntelliRoll by developing The IntelliRoll Communicator!

When our customers come to us with their problems we find solutions. This is why the IntelliRoll Communicator was developed. It began after being approached by customers wanting a way to make the IntelliRoll more easily integrated into site legacy systems or where there is no Wifi network (yet).

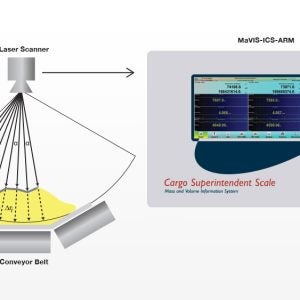

The IntelliRoll Communicator sits adjacent to a conveyor and converts the IntelliRoll Wifi signal to 4-20Ma and digital pulses. This sends totaliser, flow rate and belt speed information from your IntelliRoll to the destination by wire. The IntelliRoll Communicator houses a power supply, 2 point analog output plug in, microcontroller and wireless access point into a radio-transparent enclosure with din rail. Additional I/O channels are available.

Consider these situations:

Some typical applications for this development will be on quarries, where short or unusual conveyors may not be suitable for conventional weighers. An IntelliRoll would suit perfectly. However, now with the IntelliRoll Communicator, even sites without a network can take advantage of all the benefits the IntelliRoll has to offer.

Another typical application for the Intelliroll is in a difficult tight spot where conventional weighers cannot either fit or be used. Access to these locations is often difficult or restricted (for safety or other reasons). Previously it was not always practicable to get close enough to the weigher to use your smart phone to connect to an IntelliRoll. Now, with the IntelliRoll Communicator, it is not necessary to be physically nearby, the full advantages of an IntelliRoll can be realised despite the inaccessibility.

Similarly, on a large mine sites with remote conveyors that are beyond the reach of your networks, CST now has an advanced IntelliRoll solution using the IntelliRoll Communicator.

The IntelliRoll is bringing weighing capability to whole new markets in agriculture, waste management, quarrying and smaller mining operations as well as a new level of data gathering for process control in large ore processing plants.

Although new tech is often intriguing, it is not always appropriate or available to all sites and in all situations. CST conventional weighers are bigger, stronger and more rigid than typical competitors’ units for given circumstances in order to achieve higher operational accuracy rather than just claimed accuracy. Communications can be by 4-20Ma and digital pulses or Modbus as standard, various optional protocols, or even by 5G modem for remote access by internet. These larger weigher solutions also provide custom design for specific needs and longevity considerations for each individual application.

CST, with nearly 40 years of market leading innovation, are committed to being the best belt weigher company in the world by providing the most stable and most accurate products, calibration services and weighing equipment. We are constantly researching and working closely with our customers to learn more about real day-to-day issues, and consequently provide valuable solutions for material transfer on conveyors.