Sir Meccanica SpA is a world leader in the production of portable machine tools.

Since 1991, the company has been producing tools for onsite operations, including in-line boring, overlay welding, flange facing, turning, drilling, and tapping. With all of its products, the company strives to achieve the fundamental principles of innovation, reliability, and quality.

Sir Meccanica aims to meet its clients’ needs. As the mining industry evolves, clients require more than a simple machine tool; clients need a customised tool that is specially designed for their needs.

We are certified by:

UNI-EN-ISO 9001 Certification: application of rigorous procedures in the business management process.

- CE certification (N° IMQ 192): products’ conformity to the safety prerequisites foreseen by communitarian directives.

- GOST Certification: products’ conformity for the exportation to Russia.

- Nato Code (NCAGE AFA 74): official supplier of materials and services for the Government of the United States of America and of the American bases in Europe.

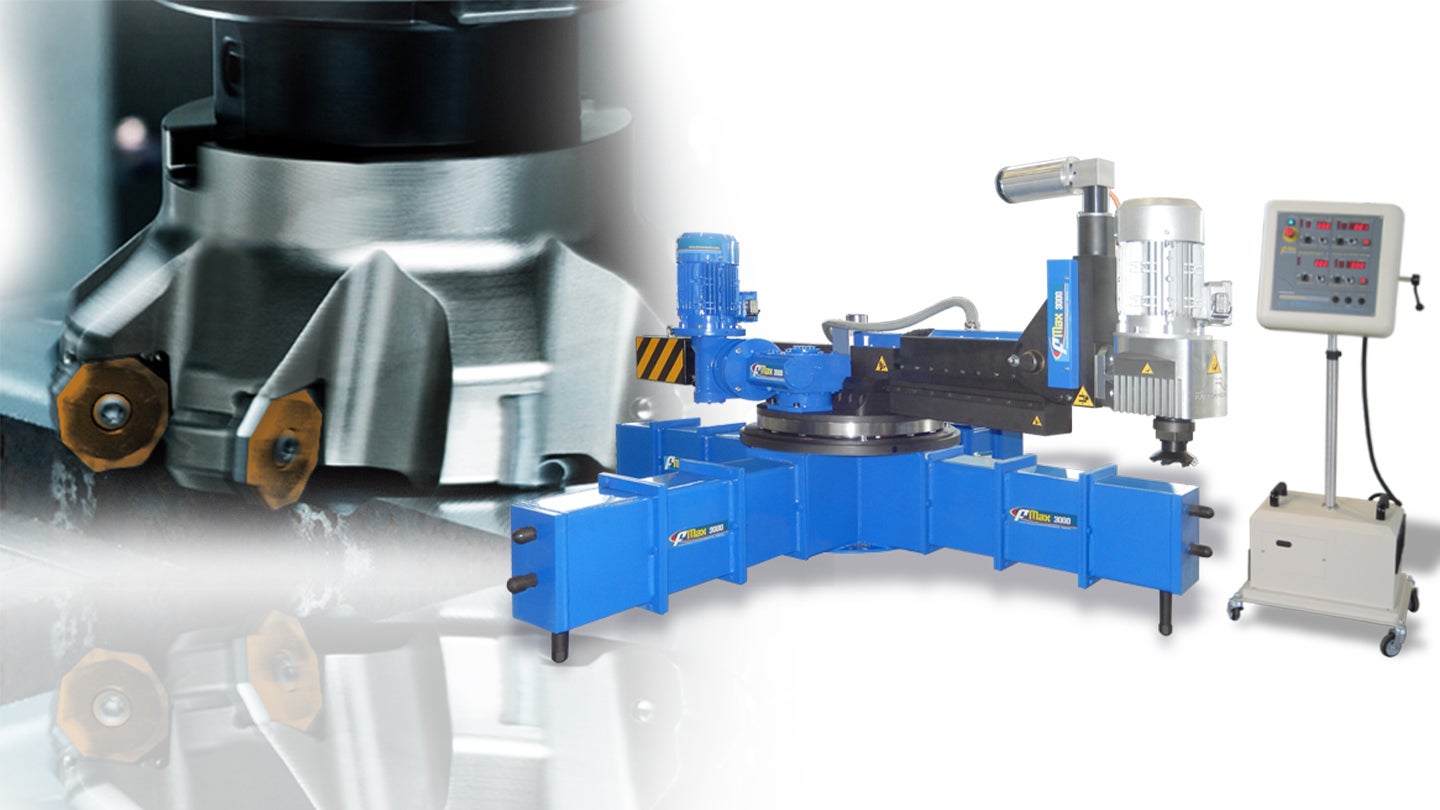

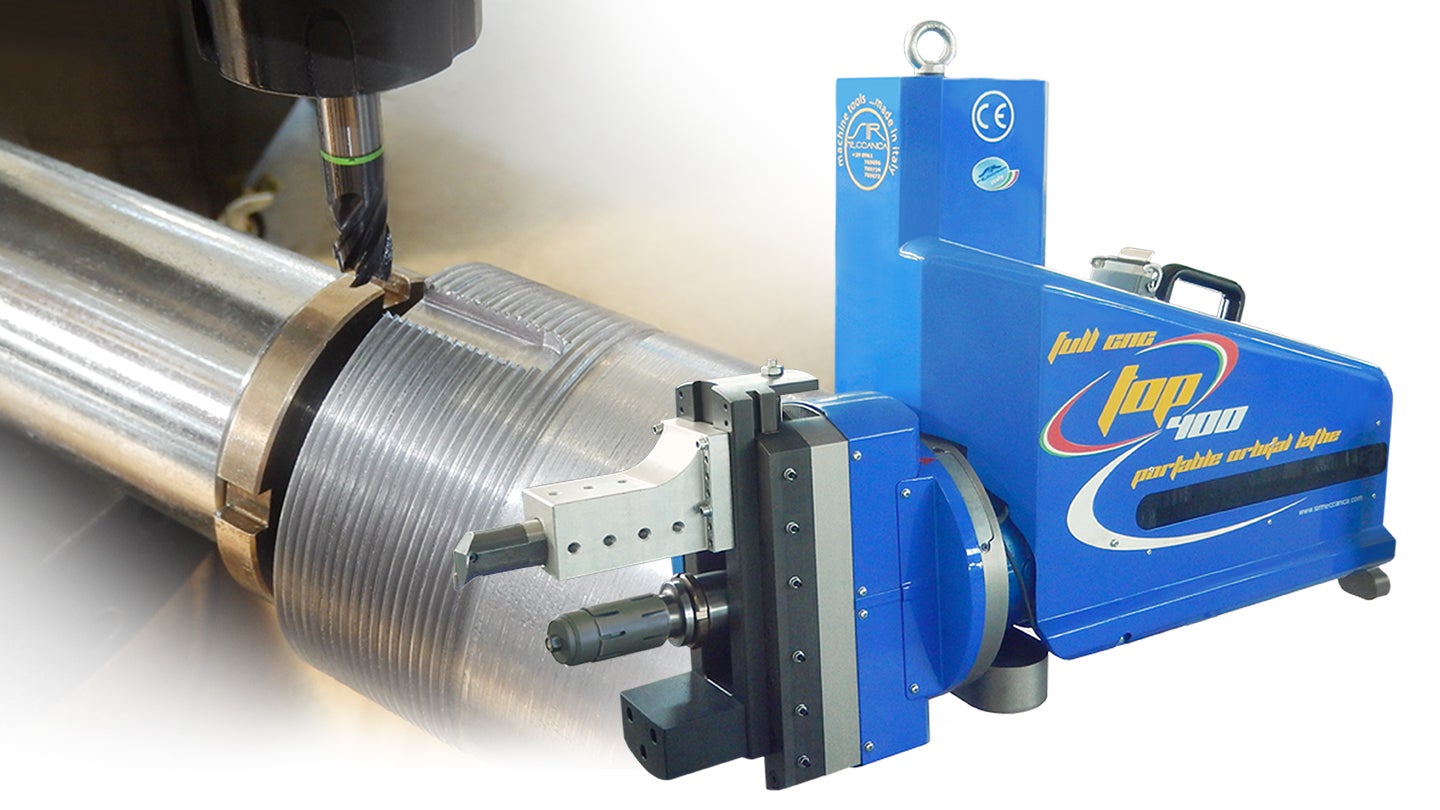

Portable machining tools for mining operations

Our portable machine tools perform, with extreme precision and in one single set-up, on-site repairs of worn holes and heavy equipment articulated joints of big and small dimensions.

They allow to perform maintenance on heavy machinery mostly used in mining, earthmoving, nuclear plants, gas and petroleum extracting towers, marine and industrial sectors.

The key advantages of these portable tools are: maintenance performed directly on-site, reduction of 85% of the machining time, no equipment disassembly. Transportation and labour costs are also reduced.

Customisable solutions for mining applications

More than 30 customisable models are available in order to cover all machining operations and working diameters.

Sir Meccanica’s portable machine tools are easy to set up and can be used onsite to repair worn holes and heavy equipment articulated joints with extreme precision and reliability.

The company’s tools are suitable for a variety of applications and are used throughout the mining industry. The portable tools are extremely useful for the repair of heavy machinery, including excavators, wheel loaders, cranes, and bulldozers. The portability of the tools also means that they can be used to repair machinery of any size.

Control panel to monitor rotation and feed speed

Every machine is powered by an Electronic Control Panel that allows the operator to set and monitor both rotation and feed speed.

The patented ESPS system automatically and proportionally reduces the feeding speed to avoid the overload of the machine in case of an incorrect setup of the parameters.

The control panel of the CNC machine tools is enriched by a touch screen display with a user-friendly CNC interface. This allows the operator to execute manual and CAM created programs.