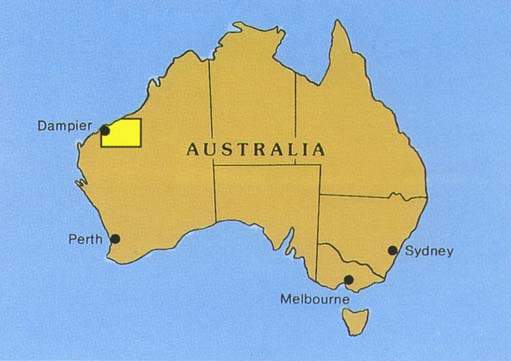

Nagrom offers a wide range of metallurgical testing services, geochemical analysis, process engineering and design, pilot plant fabrication and refurbishment. The company’s facility is based in Kelmscott, Western Australia, and is host to more than 100 processing units and an experienced workforce dedicated to finding the right solution for your mineral processing and analytical needs.

Metallurgical testwork and mineral processing

Nagrom’s expertise and experience covers many ore types and minerals, including iron ore, rare earths, mineral sands, tantalite, gold, scheelite, magnetite and more. The company’s range of mineral processing and metallurgical testwork services covers sample preparation, sizing and comminution, gravimetric, densimetric, magnetic, and electrostatic separation, hydrometallurgy, flotation circuits and more. Nagrom can facilitate projects of any size with its large-scale, custom-built processing units onsite.

Gravity separation has been one of Nagrom’s long-term specialities from the company’s time as a major tantalite processor. With an array of onsite spiral separators and wet and dry shaking tables, Nagrom has the expertise and equipment to explore gravity separation options for any ore. The company also has a range of speciality bench scale testing units, including gravity gold concentrators, Falcon separators, allmineral allflux and reflux classifiers.

Nagrom’s hold on densimetric separation has strengthened in recent years. In 2011, the company fabricated two custom, large-scale pilot processing units: a 3tph jig plant and a 5tph 250mm dense media separator (DMS). Nagrom is also host to multiple test scale DMS and allmineral jig units.

Magnetic separation units for rare earth mining

Recent activity in the rare earth mining industry has led to extensive internal research and development of Nagrom’s magnetic separation units, namely its wet high-gradient magnetic separation (WHGMS) units.

The company is home to a testing WHGMS500 unit and a 3tph Pilot WHGMS800, both capable of reaching 10,000 Gauss. Nagrom’s magnetic separation capabilities are not limited to WHGMS testing; the company is also host to Davis tubes, pilot and bench scale rapid disc magnets, wet high-intensity magnetic separators, an array of wet and dry drum magnets, and more.

Hydrometallurgy makes for a large section of Nagrom’s recent research and development. Nagrom services clients and deposits worldwide, using its comprehensive grasp of cutting-edge hydrometallurgical methods and techniques.

Geochemical analysis

Nagrom’s analytical laboratory is fully equipped for a wide range of analytical services, including X-ray fluorescence (XRF), inductively coupled plasma (ICP) analysis, mixed acid digests, peroxide fusion digests, gravimetric loss on ignition (LOI) and carbon and sulphur analysis.

Nagrom recognises that obtaining accurate results within a short turnaround is crucial to ensuring the uninterrupted progress of a project. The company’s thorough quality assessment and quality control measures, along with its dedication to producing timely results, ensure that your analytical needs are met.

Pilot plant design, fabrication and refurbishment

Nagrom has in-depth experience in the metal fabrication and plant refurbishment industry, and the company’s fabrication division has serviced small-scale pilot plants, up to the refurbishment of a 35tph tantalite recovery plant. The in-house fabrication workshop specialises in light to medium steel fabrication for the mineral processing industry, augmenting the services offered by the company’s metallurgical division. These two services, combined with Nagrom’s process engineering and design team, provides a truly customised experience and enable the customer to find the right processing solution.

Nagrom also owns the exclusive distribution rights for LINE-X® Protective coatings in Australia and New Zealand. LINE-X protective coatings are proven to be some of the world’s best. Many of the LINE-X products are well suited for long term asset protection and maintenance in the harsh environments of the mining industry.

About Nagrom

Nagrom has been an integral part of Western Australia’s mining success story for 40 years. The company provides services to mining companies and their operations, both within Australia and overseas. From starting out as a major processor in the world tantalite supply chain, Nagrom has now consolidated its reputation as a quality provider of metallurgical services.