Innovative Mining and Engineering Solutions (IMES) was founded in 2010 and specialises in plasma transfer arc welding, also known as PTAW. The IMES facility is based in Mackay, Queensland, and boasts 720m² of covered floor space with a further 740m² of concrete hard stand area outside.

IMES can cater for a wide range of work to support the mining industry, and with over 25 years combined experience, the company can offer substantial knowledge and expertise in most areas. IMES has three PTAW machines and a 2t rotator to cater for all customer requirements.

The company focuses on providing its customers with high-quality products and an unsurpassed on-site service. Today’s economic conditions require an innovative approach to finding solutions for our customers which are not only cost effective but also increase on-site safety. IMES constantly reviews its working practices in order to achieve the best results.

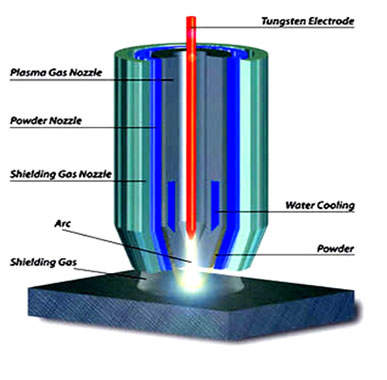

Plasma transfer arc welding (PTAW)

PTAW technology has been developed in Europe and North America over the past 15 years and now forms an integral part of the mining industry throughout the world. It is a unique welding method, with plasma being focused and forced through a heat-resistant anode, causing an increase of the arc density, energy and temperature.The welding filler alloy (in micro-atomised powder or cold wire form) is conveyed into the plasma arc column where a shielding gas protects the weld pool from the atmosphere.

IMES can apply PTAW technology to almost all steel components that suffer from wear-resistance and corrosion problems. With a wide range of PTAW powders to choose from we are able to match the right powder composition to each individual job. Using the PTAW process on steel components can increase service life by over four times the usual amount.

A wide range of products can be treated, including ground engaging tools, adaptors, teeth, cutting edges, ripper boots, ripper shin guards, grader blades, shredder bars, hammers, rock crushers, grizzly bars and chute liners.

Fabrication design services for the mining sector

A sizeable workshop allows IMES to design and fabricate a wide range of equipment from chutes, grizzly fingers, latch bars and levers, walkways and stairs, motor stands, bases, guards, and much more.

The company also has the ability to draw 3D models for its clients and a full drafting facility where we can visit sites and work closely with clients to design purpose-built equipment.

Mining site services and monitoring

IMES can provide supervisors, boilermakers and fitters for maintenance days, shutdowns and breakdowns. Work is carried out using mine site compliant vehicles with welders and tooling to carry out most jobs. Vehicles carry one diesel welder, one 32A welder (running off diesel), one air compressor and a wide range of tools to cater for all types of work.

Site inspection on products with reports on running costs, downtime tracking, maintenance scheduling, forecasting and inventory control is another service offered by IMES. This is catered to each customer’s individual needs and requirements.

Wear parts and castings for mining equipment

IMES offer a wide range of wear parts to suit most applications from dragline buckets, truck trays, excavator buckets and chutes. We have access to some of the best foundries in Australia and overseas, facilitating the design and supply of any castings to ISO 9001 accreditation. Our range consists of wear strips PTAW, wear plate PTAW, chromium overlay plates, white iron, domite and Ni-Hard. All of these available a wide range of shapes and sizes.