McNeil Engineering offers laser scanning technologies and comprehensive design services, including 3D modelling, for a wide range of industries.

Our portfolio also includes building information modelling (BIM) solutions and computer-aided design (CAD) models.

Laser scanning solutions for the mining industry

McNeil Engineering is an industry leader in laser scanning technologies.

Laser scanning offers increased detail, accuracy and cost-efficiency. It can also automatically capture up to 50,000 survey points a second. Additionally, the processed scan data can be directly embedded into design documents such as AutoCAD drawings.

Our surveying services include American Land Title Association (ALTA) / New Source Performance Standard (NSPS) land title, topographic / utility, route and boundary, and cadastral and retracement surveys.

We also perform construction staking, geographic information system (GIS) data acquisition, and subdivision and condo plats.

HDS scanning services for data capture applications

McNeil Engineering’s team of high-definition survey (HDS) team experts is experienced in the fields of data capture and registration.

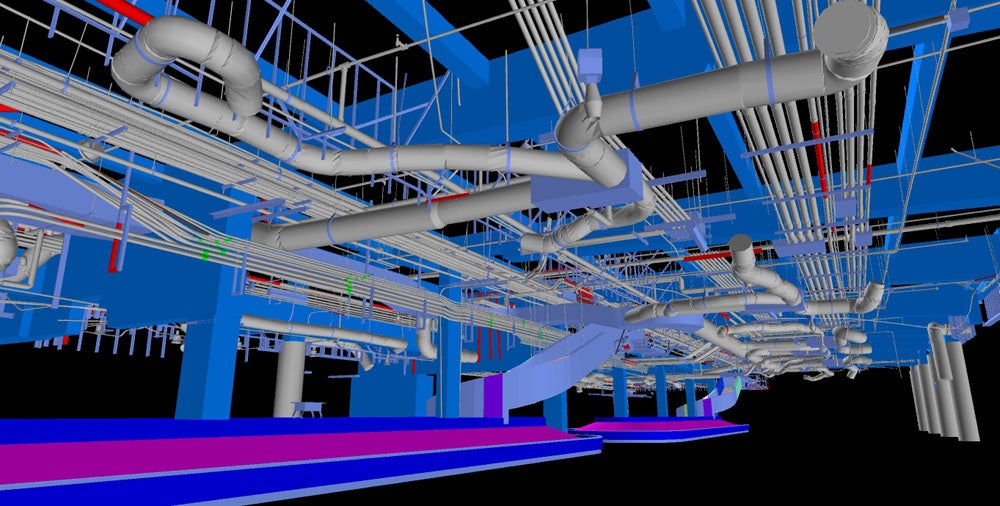

Available deliverables include archival point Cloud models, 3D CAD/BIM models and 2D CAD drawings.

Our HDS services are aimed towards the mining, transportation, construction, forensics, preservation and surveying industries.

Applications of 3D laser scanning

3D laser scanning is a non-intrusive method of rapidly collecting detailed and accurate data for project documentation.

A 3D laser scanner emits a narrow, eye-safe laser beam that collects millions of closely spaced measurements by sweeping across target areas such as bridges, roads or structures.

These scanned measurements are grouped into a comprehensive point Cloud database that can be easily accessed on a standard desktop or laptop computer.

This data can be viewed, navigated, and analysed similar to a 3D model created in a traditional computer-aided design (CAD) system.

HDS can also be used to create or perform virtual walkthroughs, interference detection, containment analysis, interactive 3D models, demolition plans, critical move plans, quantity takeoff, inventory management, and deformation analysis.

Previous projects

Rio Tinto’s iron ore mining in the Pilbara Region of Western Australia began in 1966. The current output in that region is 237 million tons of ore annually, with plans to increase output to 360 million.

Rio Tinto needed to complete a risk assessment for insurance purposes. McNeil Engineering was tasked with providing scan data for many of the facilities, including the C10 Tower and ship loaders. McNeil Engineering utilized laser scanning technology to complete this project.

Using the data collected by McNeil Engineering, Rio Tinto was able to have Models created to assess potential damage based on variable risk factors.

As Rio Tinto saw the benefit of laser scanning technology, McNeil Engineering was directed to scan more locations than originally contracted.

McNeil Engineering was able to provide more accurate data in a shorter amount of time as compared to using traditional survey methods, thus saving time and money for the client.

About McNeil Engineering

For more than 30 years, McNeil Engineering has thrived on establishing personal relationships and providing quality designs to its clients.

Committed to delivering timely, responsive and economical design solutions, we become part of the team to thoroughly understand our customer’s vision, the economics of our projects and the requirements of each customer.