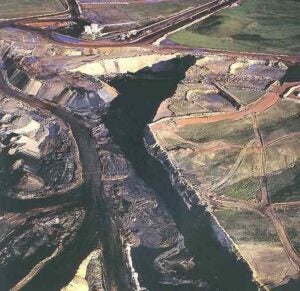

IDS Slope Monitoring Radar Supports the Prediction of a Massive Slide at Bingham Canyon

At IDS we are proud to announce that our technology has aided KUC technical staff in the quest to increase mine safety and protect the lives of their employees.

Following the massive slide which occurred at Bingham Canyon (USA), on the 10th of April, Kennecott Utah Copper (KUC) openly acknowledged the use of slope monitoring radar at their mine site as part of their slope-stability monitoring activities.

(http://www.kennecott.com/sites/kennecott.com/files/newsroom/bmc_north_wall_slide_qanda.pdf).

According to Kennecott, real-time data received through their radar monitoring systems has been used to anticipate areas that have shown movement as well as to assist inshort-term and long-term mine planning and to maintain a safe and efficient operation, before and after the slide.

"The radars scan the entire wall constantly, capturing over 380,000 images every four minutes" Ted Himebaugh, General Manager of Integrated Operations at Kennecott Utah Copper, declared to ABC 4 News. IDS ispleased to recognize that these capabilities, unique to the IBIS radar system, have been openly acknowledged by KUC for the safety-critical monitoring of the northeast wall in the Bingham Canyon mine. In fact, geotechnical engineers can benefit greatly from the capabilities of modern slope monitoring radar, such as the aforementioned IBIS system, in collecting high resolution images of entire open pit slope faces over a short scanning period and at a long range, far removed from the areas at risk within the mine.These capabilities allow the radar to track the movement history of a mine wall from start to finish, by first detecting initial small movements and accelerations and then detecting the large movements immediately preceding aslope failure. Additionally, this type of system can alsoprovide relevant alerts and alarms based on user defined velocity, acceleration or inverse velocity thresholds.

Due to their wide area of coverage, two of the three IBIS radar units installed in the pit at Bingham included the northeastern wall where the slide occurred and supported the local geotechnical engineers in first detectingthe movement in early February. The radar units measured the accelerating trendof the slide in March, indicating the progressive nature of the movement, which, according to KUC, reacheda velocity value of 2 inches per day on the 10th of April, the day of the failure.

"In some of the other days without that technology we might have been mining differently," Ted Himebaugh said to ABC 4 News. Despite the massive slope failure no one at the mine was injured. KUC was aware of the slope movement and had been monitoring this movement for months in advance through a combination of radar, prisms, and geotechnical sensors. By Wednesday morning, on the 10th of April, all mine personnelhad been evacuated from the area surrounding and below the slope that was predicted to fail. The slide occurred at approximately 9:30 pm, on Wednesday evening.

This is anexcellent example of how a modern slope monitoring program that integrates the most advanced technologies, such as slope monitoring radar, can support the decision-making process in relation to an impending slope failure at a large open pit mine such as Bingham Canyon.

IBIS FM is the most advanced interferometric radar system designed by IDS Ingegneria Dei Sistemi. The radar system is able to continuously monitor and measure mine wall movements,24 hours a dayand 365 days a year,with sub-millimeter accuracy at great distances, up to 4 kilometers. The radar system provides reliable early warning for progressive slope movements, which potentially lead to failures of mine walls, and can map the long term evolution of slow moving slopes.

IDS ishonored to contribute to the safety of the mining community on a daily basis,by supplying state of the art radar technology for safety-critical slope monitoring.

For further information please visit Prof. D. Petley’s blog at the followinglink:http://blogs.agu.org/landslideblog/2013/04/16/is-the-bingham-canyon-copper-mine-landslide-the-most-expensive-single-mass-movement-in-history/