Emesent, a global leader in autonomous digital mapping, has launched a new solution for identifying and monitoring underground mining displacement and rock movement.

“It can be extremely difficult to predict where deformation in an underground mine is likely to occur, so the ability to operationalize the monitoring of change and convergence across an entire excavation is very important for safety and productivity,” said Emesent co-founder and Chief Strategy Officer Dr Stefan Hrabar.

Traditional convergence monitoring techniques involve tedious manual workflows and do not provide a complete picture of the changes.

As a result, many mining operations are falling short in the frequency and extent of their monitoring efforts, often unable to meet the standards they aspire to or that are necessary for optimal safety and operational efficiency. Complicating things further is the large amount of time and manual effort required to process the data to achieve analysis-ready outputs.

The predominant method for assessing change in underground mining is damage mapping, which entails annotating two-dimensional section views of the mine to highlight areas of damage. While this approach allows for coverage of a considerable area, it is subject to human error.

Alternatively, tape or digital extensometers are used to measure specific points within the mine. While these devices offer high levels of accuracy, the results cannot represent change across an entire excavation. Meanwhile, more advanced technologies such as total stations or fixed laser sensors are highly accurate, however, they are constrained by their limited coverage.

Emesent’s solution combines the efficient and versatile data capturing capabilties of their Hovermap scanner with the advanced data processing and alignment capabilities of Emesent’s Aura software.

“We approach this critical business problem by applying our leading SLAM-based mapping technology,” said Dr Hrabar. “This allows quick mapping of extensive parts of the underground workings, with Hovermap either mounted to a drone, light vehicle, or used as a handheld scanner.”

In addition to speed, Emesent’s solution delivers a simplified, easy-to-use workflow which eliminates the need for data segmentation or manual alignment, making it ideal for long scans such as declines.

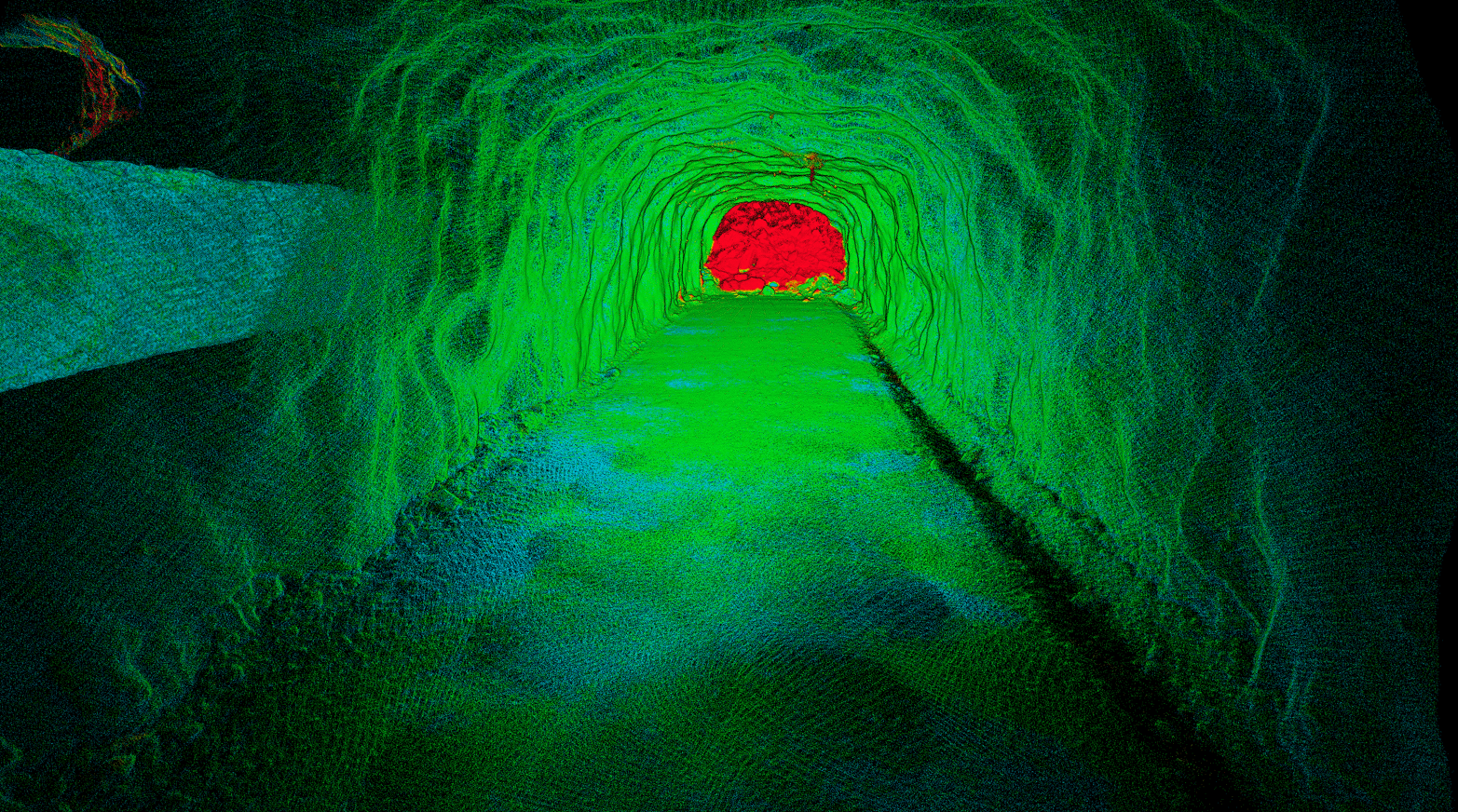

“Once the data is captured, our processing and visualization software Aura automatically aligns the scans and generates a heatmap of changes. This can be analyzed by geotechnical engineers to identify areas of concern,” said Dr Hrabar.

While minimizing the need for user input, the Emesent solution also ensures there is no need for third party software to produce and visualize the results. The data can however be exported in a standard format and combined with other data if needed for further root cause analysis. This allows for more regular and widespread monitoring of change, helping geotechnical engineers to make more informed decisions and reduce risk.

“Our Convergence Monitoring solution is yet another example of our focus on ensuring operational safety and productivity in mining. By applying SLAM-based LiDAR mapping to the problem of rock movement across large areas, we are simplifying the way sites can meet their ESG obligations,” Dr Hrabar said.

To learn more about Hovermap, Aura, and Emesent’s Change Detection and Convergence Monitoring Solution visit the Emesent website.

For a demonstration of Emesent’s solutions please book a demo.

For media related questions please select Contact the Marketing Team when you submit an enquiry.