With the development of its new high-speed turbo (HST) technology, BOGE is ushering in a new era in compressed air.

The expert in compressed air is achieving decisive improvements compared with the current, state-of-the-art, by radically reducing the number of components and introducing an extremely intelligent design principle.

With innovative turbo drive, the HST compressors produce 100% Class 0, oil-free, compressed air, at the highest degree of efficiency and with minimal maintenance effort. Cost savings of up to 30% compared with conventional oil-free screw compressors are realistic.

BOGE is presenting this pioneering technology at ComVac as part of the Hanover trade fair.

With the high-speed turbo technology, BOGE is achieving decisive improvements compared with the current modern design: thanks to a highly efficient compression principle and minimal energy consumption, HST ensures maximum results when it comes to efficiency.

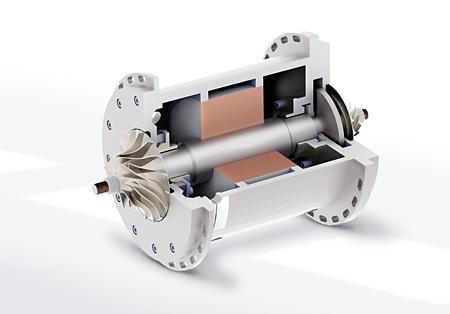

The new compressors are driven by a permanent magnet motor, which is characterised by a very high-energy density. The outstanding feature: BOGE has now succeeded for the first time in using air-lubricated bearings in the drive shaft, which is a prerequisite for extremely high speeds of well beyond 100,000 rotations.

Redefinition of high-speed

The permanent magnet motor and the unique way in which the drive shaft contains air-lubricated bearings ensure reliable, low-maintenance operation with minimal energy requirements.

Impellers manufactured from high-quality titanium that rotate at high speeds and sit at the ends of the motor shafts set the intake air in motion. The kinetic energy is particularly effectively converted to pressure energy in conjunction with the diffusor and the spiral housing.

A sophisticated cooling concept ensures effective cooling of the air after each compression stage and the integrated frequency inverters allow the volume flow rate to be infinitely adjusted to the demand for compressed air.

Concentration on the essential

HST compressors are also making a mark in terms of their longevity: The radical reduction in the number of components compared with conventional compressors makes the machines considerably smaller and lighter.

Only one movable part per drive motor was installed, and significantly fewer bearings and seals. There is no fan motor, gear unit, lubrication system or oil pump. In addition, the use of high-quality components optimised for their intended application ensures minimal wear. This concept reduces the maintenance effort considerably and ensures a high degree of reliability.

In terms of floor space, users require only half as much space as for oil-free screw compressors, and the weight is also simultaneously reduced by two thirds. In addition, the compressor can barely be heard: depending on the size, the sound pressure level is between 63 dB(A) and 60dB(A).

Best values in terms of energy efficiency

Due to the radical reduction in the number of components compared to conventional compressors and thanks to the intelligent design principle that guarantees particularly low-wear operation, there is a noticeable improvement in the efficiency values.

This is most evident in idle mode where the energy required is below 1.9% of the rated power. One of the reasons why the HST compressor achieves this extremely low-efficiency value is because there is no fan motor taking up additional energy. Overall, it was possible to reduce the total costs compared with oil-free screw compressors by up to 30%. The HST compressors are available with heat recovery as an optional extra.

100% oil-free air guaranteed

Class 0, oil-free compressed air is guaranteed with the new BOGE HST compressors: thanks to the motor shaft with air-lubricated bearings and the fact that absolutely no lubrication is used, a HST compressor is a completely oil-free compressed air system.

The fact that there is no oil system is simultaneously one of the most sustainable measures for reducing maintenance costs. Before, the machines always had to be stopped to lubricate bearings or change oil filters, but now they simply continue to operate.

Quality made in Germany

Whether as a base-load or peak-load machine, the three-stage HST high-performance compressors have already proven themselves with customers over tens of thousands of operating hours. They are the perfect solution for all users who need a continuous supply of oil-free, high-quality compressed air.

The advantages of HST compressors can particularly be utilised in sensitive production areas such as the chemical, pharmaceutical, food, beverage and semiconductor industries, as well as in refineries, breweries or paint shops. There is also the option of attaching a heat recovery system, which uses the heat expended by the compressor for service water heating or space heating.

Visit the company website for more information.

Photo: Design of the BOGE high-speed turbo (HST) compressor technology. Image: courtesy of BOGE.