SGS is specialized in the engineering, manufacturing and assembly of standard, special, large and customized industrial gearboxes for the mining and materials handling industries, and other applications with a demand for high power and extreme load capacities. SGS is able to offer short response and delivery times, as well as express deliveries of special and/or large gear components, and special and customized gears. Besides a centrally located 200m² office building, two manufacturing halls with a total of 4,800m² are available for assembly purposes.

The scope of drive applications that can be equipped with SGS reducers and components includes large rock and coal crushers, large and special materials-handling equipment, processing equipment, large milling machines, as well drives for special excavating equipment in the open-pit mining industry.

Gear units for the mining and materials handling industry

SGS is familiar with different types of gear units for bulk material handling plants, processing plants, heat and power plants, and the mining industry. Our products include bucket wheel reducers, excavator crawler track drives, slewing gearboxes, hoisting gear units, as well as standard or planetary gear units. Currently we provide some bucket wheel gear units with an output torque of 2,500,000Nm and a weight of 25,000kg each.

The achievement of our goals is based on a solid foundation of long-standing experiences and comprehensive know-how in the development, construction, manufacturing and assembly of special gear units for nearly all industrial applications.

Bevel helical gear units

We are currently designing special bevel helical gear units for the drive of overland conveyor systems, which have an electric motor powered with 2,700kW. The weight of one of these drive units is 49,000kg.

Gear repairs and refurbishments

The repair and refurbishment of existing gears is also one of SGS’ specialties. It is possible to manufacture single and unique gears in accordance with original drawings, even those produced by manufacturers that no longer exist.

Gearbox engineering, manufacturing and assembly, and spare parts

SGS provides the engineering, manufacturing and assembly of gearboxes as well as spare parts for the following applications:

- Bucket wheel reducers

- Crusher / sizer gear reducers

- Belt conveyor gear boxes / drives

- Gantry crane hoists

- Apron feeder drives

- Hoisting gear units

- Bevel spur / helical spur and planetary gears

- Planetary gear units

- Excavator crawler track drive

- Shifting gears

- Slew / slewing gearboxes and drives

- Spur gear box

- Rolling mill reducers

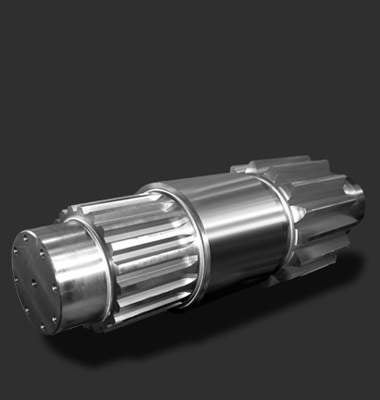

- Pinion

- Spur gears up to 7,000mm / 60t single weight / module 40

- Helical gearing

- Double helical / herringbone gearing

- Helical bevel gear stages up to 1,300mm

- Flange shafts

SGS is well known for high quality products and fast realization of complex demands. The assurance of contractual quality and delivery requirements is realized due to close monitoring and inspection of our manufacturing and assembly processes. Challenge us with your most demanding tasks and we guarantee an economically and optimized solution centralized through our management.