The Power Deck Company is a distributor of blasting accessories to mining sites all over the world. The company’s innovative range of products is designed to ensure maximum productivity and safety during blasting operations.

Power Deck Plug – Reducing flyrock, vibrations, drilling costs, and the volume of explosives used in mining projects

The company’s most popular product, the Power Deck Plug, offers dramatic reductions in flyrock, vibration, drilling costs, and the volume of explosives used in mining projects. It is widely used across all sectors of the mining industry.

Power Deck users have also observed increases in fragmentation and cast percentages while maintaining or lowering their powder factor. No auxiliary equipment, large capital expense or changes in blast design are required.

Power Deck system for blasting operations and casting applications

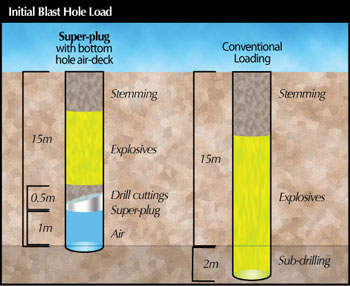

The Power Deck system is made possible by the arrangement of a Power Plug, air and mass strategically placed within a borehole to improve blast results and dramatically decrease blasting costs.

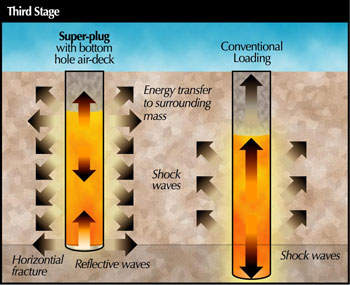

Results in previous mining projects have shown the system is capable of removing the need for 10%-50% of explosives, reducing vibrations by up to 75% and most impressively, completely eliminating air blast and fly rock. And despite reducing explosive consumption, the fragmentation distribution remains unchanged or is actually improved in some operations, while reducing the undesirable fines content in others.

It has also been proven that by focusing most of the blast energy in a downward direction, single and multiple Power Deck designs can greatly increase control. In many cases, stemming length can be reduced without increasing the danger of fly rock. Sub-drill can be reduced by up to 100%, and in casting applications the throw volume is significantly increased.

Blasting system to reduce or eliminate sub-grade drilling

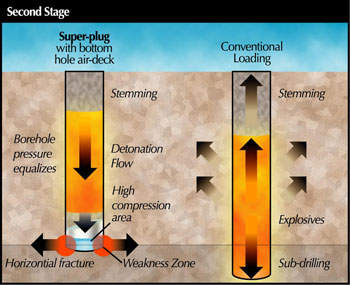

What occurs at the bottom of the hole with the Power Deck system is best explained in terms of pressure and / or kinetic energy.

When an explosive detonates in a borehole, the high temperature by-products of the detonation will always take the path of least resistance. The bottom hole in the air deck will first be subjected to an intense shock wave. After the initial shock wave front hits the bottom of the hole it creates a reflection and increases the pressure at that point.

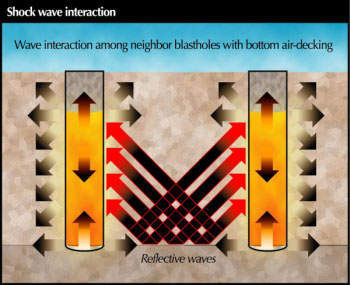

As the reflection occurs, a separate secondary impact from the explosion products adds another pulse to the bottom of the hole. The combined effect is that the resulting pressure at the bottom of the hole can be increased by two to seven times greater than the initial pressure. The increased point source pressure is sufficient to create a planar split and fragmentation.

Fundamentally, the sum of the primary shock wave energy and secondary explosion products are far more efficient than a concentrated cylindrical charge, but only when the bottom hole air deck length and Power Deck’s plug mass are properly designed for the specific field conditions and explosives system.

The Power Deck system can be used to reduce and, in some instances, eliminate sub-grade drilling. By easily dropping the pre-assembled Power Plug and bottom support into the base of the bore hole we have by default created a path of least resistance for the explosive energy to seek.

Remote firing devices for surface and underground mining

A specialist in remote firing devices (RFD), Power Deck Company provides cost-effective blasting solutions from premier manufacturers, including world-famous producer Rothenbuhler Engineering. Systems can operate either on the surface or underground and provide superior performance.

Rugged bore hole sealing device

Power Decks’ Blasthole LID allows blasters to protect the integrity of the hole. The heavy-duty sealing device is tough enough to withstand trucks driving over it, while blocking cuttings from re-entering the hole. The device is easily retrievable – even with hundreds of pounds of dirt covering it.