Mammoth Drill Tools is a company within the mining and drilling industry, supplying blasthole drilling tools. New product development is a core aspect of the business.

Our product development drive has been shaped and guided by the requirements, needs and frustrations gleaned from our clients in the global market. This has led us to develop a range of durable, cost-effective products in the various sectors of the industry.

Breakout wrench for locked drill stem joints and unsafe breakout procedures

The Mammoth breakout wrench addresses locked joints found in the drill stem as well as unsafe breakout procedures. It overcomes the lack of compatible cross platform breakout wrenches and avoids wrench-slip when loosening drill rods, hammers and bits.

The breakout wrench has fully automated, hands-free operation and is compliant with mine safety requirements. It is designed to fit the requirements of any OEM drill rig and its patented clamp action, which is slip proof, fits any specific OD requirement. Furthermore, the patented moveable bracket allows the wrench to be set at any operating height. The breakout wrench is also fully repairable.

On-site repairable shocksub for shock absorbency while drilling

In addition to reducing drill rig maintenance by dampening torsional and axial shock loads, the Mammoth on-site repairable shocksub offers a 360° vertical and horizontal shock absorbency during drilling, as well as a push-and-pull, combined with left and right rotation absorbency. It addresses wear and tear on conventional shocksub systems, as well as inadequate seal characteristics and a need for enhanced safety features.

It has the benefit of allowing use of higher pull-down force and increased rotary speeds, and also increases bit life. Aside from being rotary and DTH-compatible, the Mammoth shocksub is also fully repairable in the mine.

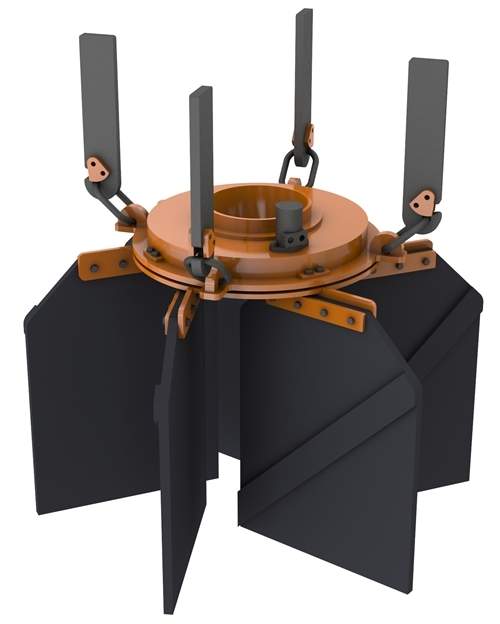

Hole sweeper for blasthole chippings and cleaning

The Mammoth sweeper is fitted to the undercarriage of a drill rig and addresses chippings ejected from a blasthole and cleaning the collar of a blasthole, with no manual labour. The rotating flaps prevent chippings accumulating around the collar of the hole and clogging below deck.

The sweeper decreases wear on the drill string and avoids the lock up of bits. It increases penetration rates, bit life, drill steel life and the life of the deckbush. In addition to the above mentioned benefits, the hole sweeper decreases contamination of the deck.

Stemlock to secure drill string

The Mammoth stemlock can be manufactured to individual requirements and specifications, and is designed and manufactured to secure the drill string securely, enabling the breakout of the drill rod and bit.

The stemlock is designed to address the drill manufacturer, drill model and rod diameter, as well as the spanner-flat size. Our standard quality manufacturing procedures and durability ensures the best performance. The product is also fully repairable.

Deckbush for drill rod centre stabilisation

The Mammoth deckbush can be manufactured to individual requirements and specification and is used for the purpose of stabilising the centre of the drill rod.

Our standard quality manufacturing procedures and durability ensure the best performance of the product.

Drill rod and sub adaptors

Our Mammoth drill rods and sub adaptors are designed to increase the length of the drill bit depth and extend drilling penetration, and can be manufactured to individual requirements and specifications.

The top sub is a short length of drill collar that has male threads on one end and female on the other. It is screwed into the bottom of the topdrive (rotary head) or shocksub, and onto the drill rod.

The bottom sub is a short length of drill collar that has male threads on one end and female on the other. It is screwed onto the bottom of the drill rod and onto the drill bit.

The stabiliser is key to providing lateral stability to the drill bit during the drilling process. Lateral stability ensures optimal functioning of the drill bit. Stabilisers add to the efficient utilisation of energy and force by limiting lateral movement of the drill bit.

Our quality control in the production of the products insures durability for the best performance and they are fully repairable.

To find out more about Mammoth Drill Tools’ products and services, please contact us using the details or form below.