In 2018, a leading Queensland mining and electricity-generating business embarked on a ‘voyage of discovery’ with Xenith, when the client was faced with ensuring their product quality could be forecast with high confidence as a direct result of an impending, major shutdown of their coal handling and preparation plant (CHPP).

Under normal operations, the CHPP assists in meeting quality parameters, however, a major outage of this key piece of infrastructure would almost certainly result in significant cost penalties with reduction of megawatt output from the power station. In addition to this, there were key quality parameters that could adversely affect power station productivity by as much as 30%.

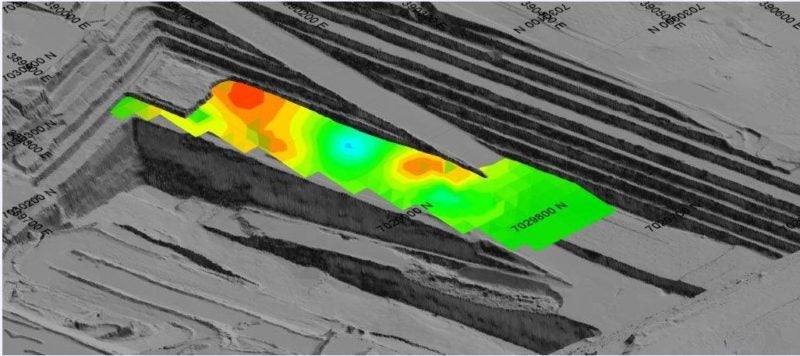

One of the key factors that were identified in managing this was the requirement to capture the in-pit, quality data and update the geological model well ahead of mining operations. If this could be achieved, more informed decisions could be made on where and when to mine rather than relying on the processing plant to meet specifications. In order to achieve this, Xenith identified a rapid response, end-to-end quality management system which it has since been named Q-Pro.

Q-Pro provides a platform for the rapid turnaround of quality hole drilling, sampling, logging, correcting and modelling ahead of the mining operations.

Following this successful trial, Xenith is keen to apply learnings from this project at other mines where the rapid-turnaround of quality information will add significant value.

In parallel with this initiative, there is an increased global focus on bulk commodity quality specifications with a rise in penalties and potential rejection clauses in sales contracts for both iron-ore and coal, as well as a number of other commodities. The reasons for this shift include an increase in environmental legislation and requirements, a more comprehensive understanding of product properties, performance and impacts, as well as corporate stakeholder responsibilities and reputation.

Xenith is well positioned to deliver significant benefits to clients via Q-Pro. This innovation is driven by a team with the necessary experience and expertise across every step of the Q-Pro process as well as having completed a successful pilot for a satisfied client.

Quote from the client:

“In October 2017, a major power supplier undertook a planned upgrade of our Coal Handling and Preparation Plant. In order to maintain the supply of coal to the Power Station during this upgrade, the generator needed to be confident that production could continue on a purely bypass basis (crushing and screening only). There needed to be confidence that the product specifications could be achieved by selective in-pit mining and stockpiling of unsuitable coals with high impurities, high ash or low energy. Using the Q-Pro in-pit coal quality service allowed the client to map coal qualities down to a 25m x 25m grid and plan the product feed and stockpiling efficiently. The short-term drilling program showed higher than originally modelled coal qualities, resulting in a successful mining campaign where 15% more unwashed coal was delivered than was initially budgeted. This reduced the risk of an outage overrun and reduced the draw-down on the Power Station coal stockpiles.”