Pneumatic conveying systems are highly effective with explosive dust mitigation during the material transfer process. Bulk material transfer can create a large amount of dust during the loading and offloading stages. Depending on the particular material and environmental conditions, that dust could pose a serious safety hazard. Explosive dust mitigation is a very important factor for any company or crew participating in an activity that creates concentrated dust. It is not always apparent if a material is combustible but it may burn or explode given the right conditions. A thorough evaluation of the materials and worksite conditions should be undertaken to ensure project safety.

Intrisically safe pneumatic solution

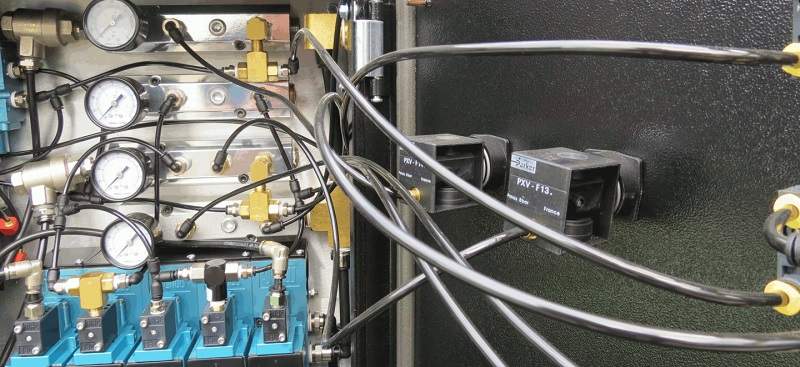

The IVAC solution to combustible dust conditions is our fully pneumatic industrial vacuum system. The main focus of our safety strategy to manufacture this system was to remove all possible ignition sources.This meant a completely pneumatic machine with few moving mechanical components. The standard control panel has all electrical components replaced with air driven switches. When the unit is placed into its’ working position the frame is connected to a grounding circuit. Industrial hose used for intake and discharge of materials is copper wound and approved for hazardous conditions. The operation of an IVAC system requires only three moving parts, the knife gates. These components do not come into contact with the material and have a nonexistent heat profile even with constant usage. With the elimination of potential ignition sources IVAC equipment helps to ensure crew and worksite safety.

Case studies

Coal mine – IVAC was contacted for consultation about coal dust carry-back buildup in the tunnels and around the conveyor belts at a coal mine. This material buildup was causing premature wear to the mechanical equipment as well as creating a possible combustion hazard. After inspection, the IVAC technician determined that if spillage from the conveyor belts was addressed before large accumulations could occur plant efficiency would dramatically increase. Also, any concerns about combustion hazards would be nullified.

Offshore drilling – The bulk transfer of proppant on an offshore drilling platform requires a robust industrial pump system. Transfer rates for this application are very demanding and dangers can be encountered if using a traditional mechanical conveyance system because of the extended heat build times and possible sparking of components. A PV500 unit with the pneumatic control panel was suggested for this situation to protect against the hazards of dust and vapours.

Sawmill – When piles of sawdust were becoming an obstacle on a lumber mill floor, management reacted to the situation by reaching out to IVAC for a potential solution. The accumulations at production choke points were slowing down productivity and creating safety concerns for work crews. The pro-active decision to install an industrial vacuum system helped the plant return to complete production capacity.