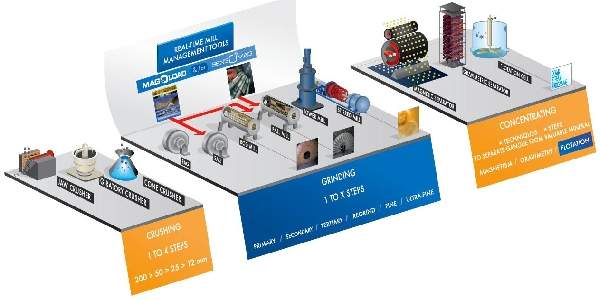

The Belgian foundry started in 1918 is now the world leader in differentiated solutions against wear. Magotteaux supply the widest range of optimized solutions against wear to the mining industry as well as products, services and systems to other industries involved in material size reduction: cement, quarries, recycling and coal-fired power plants. Magotteaux also design specific solutions for the dredging industry.

Experts in grinding media for the mining industry

Magotteaux carries out research, design, manufacturing and distribution of wear-resistant components and grinding media through the company’s extensive understanding of its customers’ needs for specific processes of production, the type of wear taking place, and the appropriate materials needed to combat abrasions.

The Belgian foundry started in 1918 is now the world leader in differentiated solutions against wear. Magotteaux supply the widest range of optimized solutions against wear to the mining industry as well as products, services and systems to other industries involved in material size reduction: cement, quarries, recycling and coal-fired power plants. Magotteaux also design specific solutions for the dredging industry.

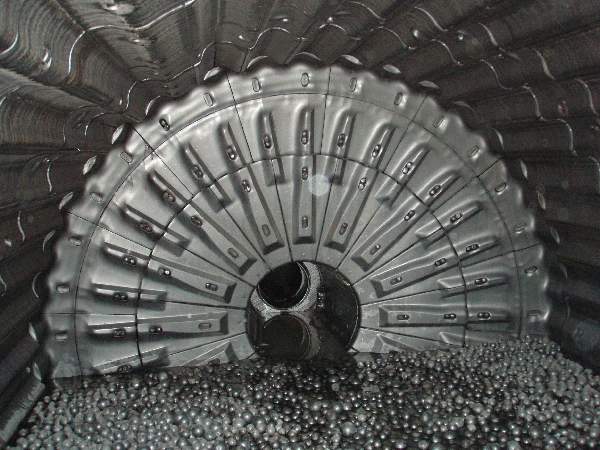

Our media can be classified in six main categories (three for mining and three for cement), each with a specific brand name with an individual reference for a specific field of application.

For mining applications we offer:

- Ecomax®, with a diameter from 50mm to 125mm and chromium percentage from 0.2% to 9.9%

- Duromax®, with diameter from 12mm to 100mm, and chromium perecentage from 10% to 35%

- Keramax® MTX™, with a diameter from 1.5mm to 3.5 mm, offering a unique inert ceramic bead for ultra-fine grinding applications in stirred mills

Grinding media specific for mining applications

Magotteaux offers help and guidance to customers, from selecting the best wear-resistant alloy, to assessing its impact on grinding chemistry, and the subsequent separation process. Research and experience have indicated that among the three wear mechanisms, corrosion is usually responsible for more than 50%.

Magotteaux promotes the use of certain grinding media as an effective method for preventing corrosion products from the media from contaminating the surface of valuable minerals.

In order to provide the optimum solution, Magotteaux has developed these specific tools:

- The MagotteauxMill®, which allows the user to investigate the impact of grinding chemistry on the metallurgical process by reproducing the chemical conditions of the plant grinding mill in the laboratory

- The Magotteaux FlotationCell™, which allows the user to continuously monitor pulp chemistry and add chemicals at any stage

Machines and systems to measure wear in mining applications

We design and manufacture specific machines and systems to help customers optimise their total cost of ownership. Among these are filling sensors, such as the Sensomag®, an automated ball addition system in the Magoload® for the mining industry, and a vertical shaft impactor for the aggregates industry, as well as a classifier for the cement industry.

Magotteaux has successfully developed relationships with major mining companies. Because of strong partnerships and our involvement from the very start of major projects, we remain one step ahead with technology.

The unique complete range of grinding media

Since the end of 2011, Magotteaux has been part of the Chilean Group Sigdo Koppers. Under our new owners, we have acquired the remaining 50% of our joint-venture Proacer and 55% of SABO Chile, which allows us to offer a complete range of grinding media solutions, such as low chromium (cast and forged), high chromium, ceramics (for stirred milling applications) and rods.

The latest development in the group is the opening of a new production unit in Thailand, dedicated entirely to manufacturing vertical mill parts.

Magotteaux employs around 2,550 people, with a market footprint of more than 450,000t of grinding media and castings. The group has a network of 14 production units, a licensee in South Africa, and 28 sales offices worldwide complemented by several technical centres. In 2011, the company’s total turnover was €550m.