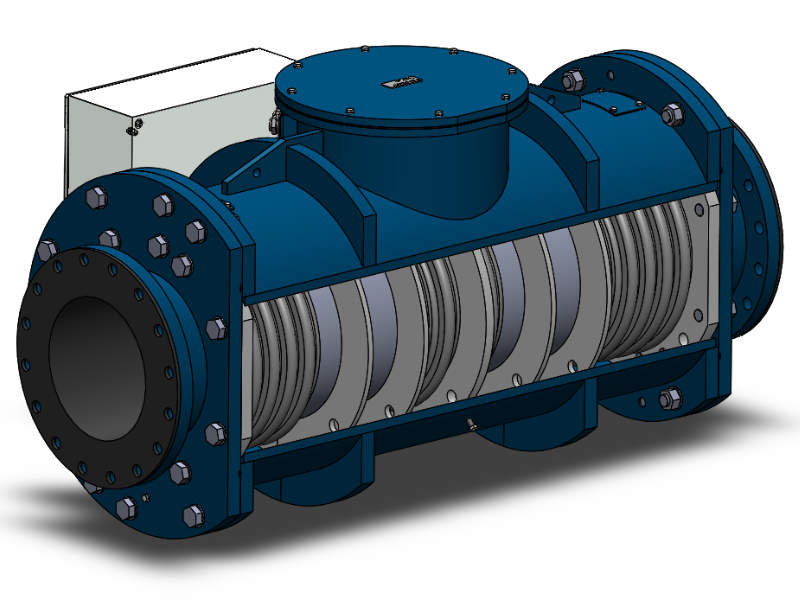

The device measures in-line slurry density in near real-time for any size of pipe, independent of external process conditions and slurry composition. This makes the Alia Density Meter ideal for use in challenging conditions such as dense slurries that contain sand, metal, rocks, and air bubbles that are present in various applications.

Slurry density measurement machinery for mining applications

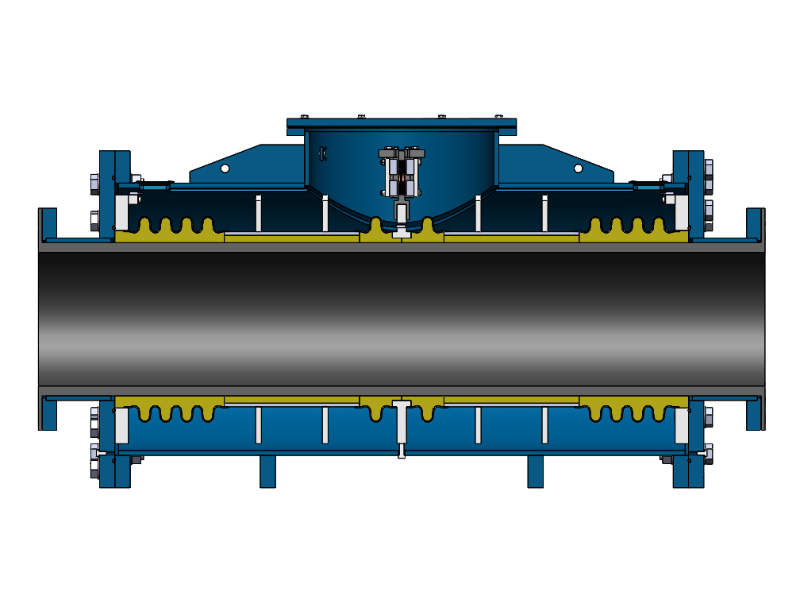

Alia Density Meter uses Newton’s universal second law of motion principle. Inside the in-line device, a force is exerted onto the slurry, its resulting acceleration is measured and the slurry mass is calculated as the ratio of both. Dividing by the known volume inside the meter calculates the slurry density.

The simple direct measurement method is almost immediate and accurate within 0.5% of a full scale. This is ideal for monitoring density in applications such as tailing and concentrate lines, quality control purposes to monitor process consistency, and preventing pipes from becoming clogged by slurries that are too dense.

Density is measured under dynamic conditions, but it can also be measured in non-flowing stationary fluids.

Alia Density Meter provides accurate measurement results from pipes of all diameters, including large internal slurry pipe diameters.

Density measurements are independent of slurry composition as Newton’s law applies to everything that is inside the slurry pipe, including water, sand, metal, high-density sediment and air inclusions. This is an advantage compared to other working principles as the accuracy is often reduced in large pipe diameters with high slurry densities.

Density meters for optimised mining processes

The Alia Density Meter is ideal for use as part of a mining production meter, where the combination of flow and density provides valuable data about the efficiency of the mining process.

Meters are used in slurry streams around dewatering processes in the mining of metals and minerals. They can save large amounts of water by providing an accurate and immediate reading of slurry densities, resulting in optimal use of available resources.

Density measurement equipment for radioactive material

The Alia Density Meter avoids issues that are related to radioactive technology, with no legislation constraints, transport or disposal of nuclear sources, special training in nuclear technology for maintenance engineers, and need to carry out checks and repairs. This helps to improve sustainability and social responsibility for users of the density meter.

Density calculations are unaffected by the meter’s surroundings, including temperature variations and external vibrations caused by other machines or components. Vibrations are measured and will be compensated for in the mass calculation. Active damping further suppresses the effect of external vibration. The meter can be installed horizontally, vertically or at a tilted position.

Low maintenance density measuring for mining

Alia Density Meter is easy to install mechanically in the slurry pipe, connecting to an electrical power supply, as well as an external control and read-out device as part of the meter. It can be easily integrated with existing systems and software.

After installation, the meter requires little maintenance. In highly abrasive applications, the rubber tube that has direct contact with the slurry will need to be replaced a few times during the density meter’s service life.