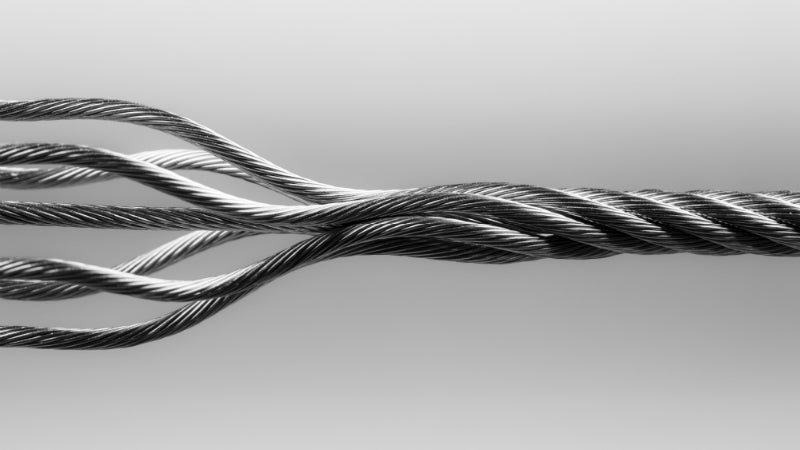

Northern Strands supplies wire rope and associated rigging supplies to the mining and industrial sectors.

By working with customers in the mining industry, the company provides products and technical assistance for complex hoist installations worldwide. Northern Strands offers a full line of wire ropes, for a wide range of lifting applications.

Wire rope for mining applications

Northern Strands supplies wire ropes for ground and tower-mounted friction (Koepe) hoists, drum hoists, and Blair hoists.

There are many factors to consider when choosing the right product, including:

- Resistance to drum crushing

- Resistance to rotation

- Strength (also known as minimum breaking force)

- Resistance to fatigue wear

- Corrosion resistance

- Service life

- Rope flexibility

- Rope diameter

- Weight per foot

Friction (Koepe), drum, and Blair hoist ropes

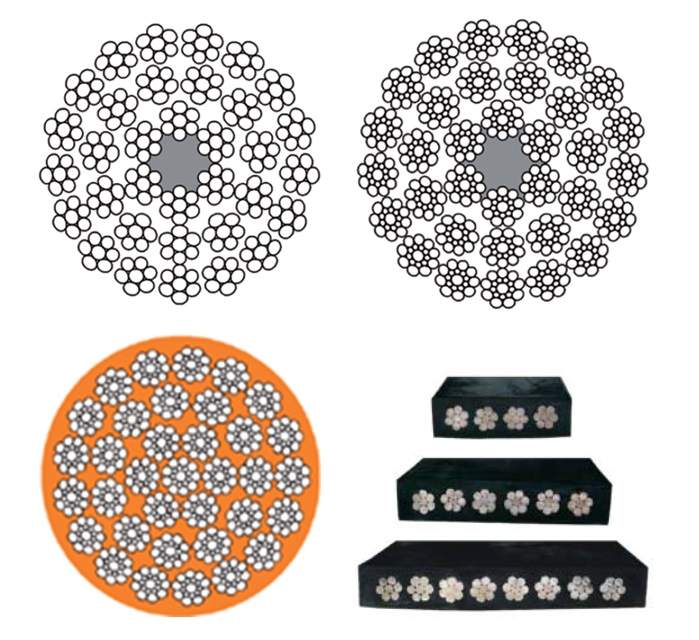

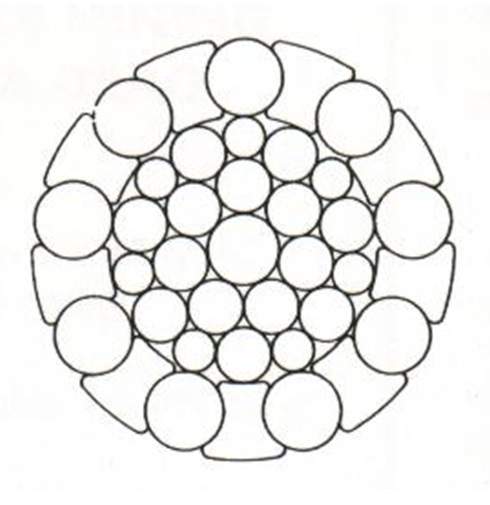

There are a variety of wire rope constructions that can be considered for your hoisting operation, including 35×7(multi-strand) construction, 24×7 or 24×17 construction, flattened strand, 6-strand or 8-strand, and full lock coil.

Balance (tail) ropes

Northern Strands offers friction (Koepe) hoist balance (or tail) ropes if needed in 34×7 or 34×17 construction, both of which have the option of plastic outer cover and plastic filled valley, or flat balance with rubber exterior and rubber between the wires.

Sinking ropes

For sinking ropes, a rotation resistant rope is required. As the shaft gets deeper, the resistance to rotation becomes critical, and a high-performance design from Northern Strands is necessary.

Guide ropes

For guide ropes, half lock coil ropes are the most commonly used product. Full lock coil ropes are also a consideration in some circumstances. Northern Strands helps to provide the best guide rope for the job depending on the diameter, breaking strength requirements, and the mine environment.

Slope hoists and surface mining

In addition to underground ropes, the company can also supply wires ropes for slope hoists and surface mining.

Flattened strand, 6-strand, and 8-strand are the most common varieties. The number of wires, level of compaction, and inclusion of plastic are all part of the design process.

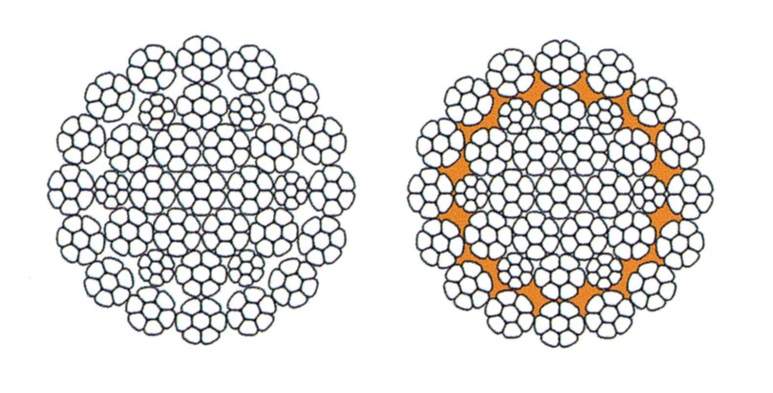

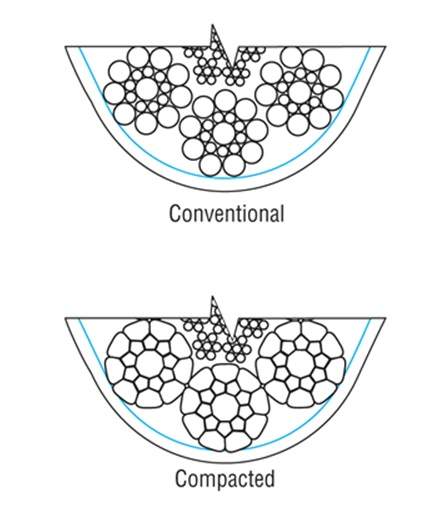

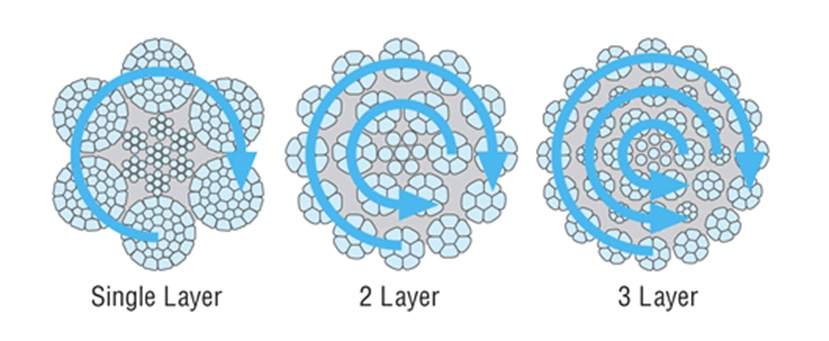

Compacted strands

Many Northern Strands hoist and sinking ropes come with compacted strands on the outer layer, inner layers, or all layers. Compacted strands have several advantages over round strands, such as:

- Higher metallic area

- Higher breaking force

- More resistance to side pressure, wear, and abrasion

- Better spooling performance and resistance to crushing

When designing rope, strand compaction can be altered to meet certain requirements.

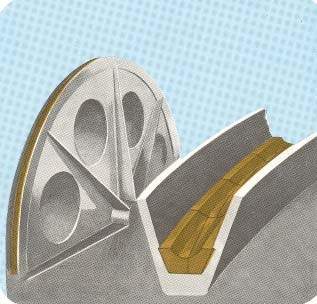

Plastic covered core

In hoist ropes with plastic-covered cores, a plastic sheathing is inserted between the outer layer of strands and the inner layers. This reduces potential sliding of the various components while still allowing for the necessary movement.

The plastic also fills the free space between the exterior strands, which noticeably prevents friction wear damage. One of the biggest advantages of this product is its ability to seal the lubrication in the inner strands, and keep out the polluting agents that lead to corrosion.

Bright, galvanized, and aluminium-zinc rope finish

Corrosion resistance can be obtained by using different rope finishes.

In a dry environment, ropes are made with bright steel. In a wet environment, ropes made with galvanized wires are recommended. In corrosive settings, wires coated in an aluminium zinc alloy (also known as galfan) is the best choice.

Wire rope lubrication

Lubrication of wire rope is important. It is required during manufacturing, installation, and ongoing maintenance. Different hoists and applications require different types of lubrication.

With Northern Strands’ knowledge of wire rope, it can recommend and supply appropriate lubrication products and suggest the best lubrication methods.

A full range of wire rope attachments

Northern Strands offers a full range of attachments for all mining ropes, as well as a comprehensive inventory of installation equipment for purchase or rental, along with installation crews.

All attachments are designed and engineered to national coal board standards, as well as government regulations.

Attachments are manufactured to a high-quality standard, governed by ISO 9001. All are wet mag particle tested, ultrasonic tested (UT) and proof loaded, and come with certified welder (c/w) test certificates. The major advantage of manufacturing in-house is that the company can control costs and delivery.

The company provides a wide range of attachments for several varieties of ropes. For hoist ropes, these include:

- Wire rope sockets

- Wedge capels

- Thimble capels

- Solid thimbles

- Hydraulic fine adjusting linkage

- Chaseblocks

- Mechanical adjusting linkage

For balance ropes the following are available:

- Sockets

- Apex clamps

- Wedge capels

- Chaseblocks and pins

- Swivels

- Solid thimbles

- T-bar

- Quick release style

Northern Strands also offer attachments for guide ropes, such as:

- Cheeseweights, rods and platforms

- Tensioning gear

- Spherical seated gland

Installation:

- Manoeuvering glands

- Kellems grips

- Suspension glands

- 2-bolt blocks

- Swivels

- 2-bolt blocks

Shaft sinking:

- Swivels

- Sheaves

- Hooks

- Buckets

- Bucket chains

- Load cell

- Sockets

- Dolly balls

About Northern Strands

In addition to wire rope and attachments, Northern Strands supplies rigging, training, suspended access equipment, and engineered fall protection equipment.

Northern Strands has been serving the mining industry for more than 45 years and is certificate of recognition (COR) safety certified, and a Mission Zero member. In support of Mission Zero and their safety in the work place message, Northern Strands is a major sponsor of Saskatchewan Health & Safety Leadership Charter Event and the Mission: Zero Awards.