For the machinery and equipment used to extract, transport and process in mining, access can be remote or restricted. Therefore, the unexpected failure of a single component can bring an entire site to a standstill at a significant cost.

Durability and reliability are paramount to bearings used in conveyor applications. For the arduous and highly contaminated operating conditions that prevail, NSK has developed 3D – Triple Defense to keep conveyors in motion.

NSK specialises in bearing solutions for a wide range of pulleys, including head, tail, snub, bend and take-up variants.

3D delivers maximized productivity, minimal unplanned downtime, extended bearing life, maintenance-free sealing options, and reduced total cost of operations.

Hi-TF Series bearings

Hi-TF bearings were engineered for outstanding toughness under the harsh conditions of marginal or contaminated lubrication. They combine a dramatically tougher steel formulation with proprietary heat-treatment technology, to deliver up to ten times longer service life and superior resistance against wear, seizure, and heat.

Other advantages:

• Up to four times the service life at 160°C

• Less than one-third the rate of wear

• As much as 40% improvement in seizure resistance

• Additional applications include conveyors, crushers, compaction equipment, pumps, headframes, ball mills, sizing mills, CBM, and centrifuges.

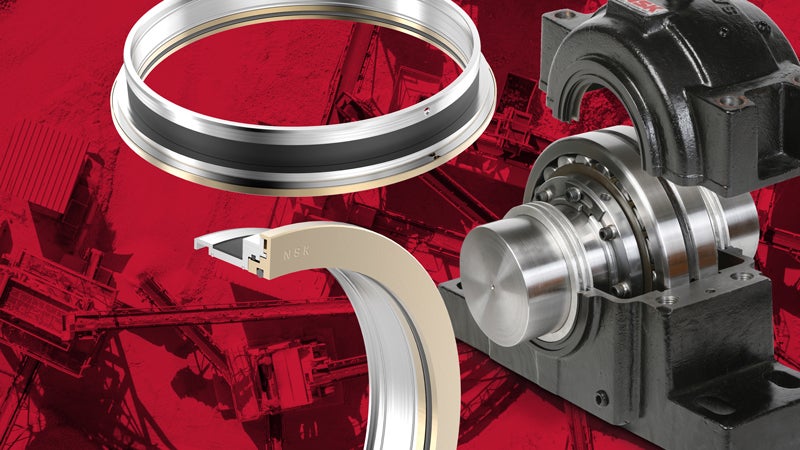

HI-TF spherical roller bearings with a removable seal

Combining our Hi-TF material technology with an advanced and easy-to-install seal, NSK delivers a high-capacity, high-performance solution to contaminant-related bearing failures in conveyor applications.

Features include a high-performance seal design, including engineering features to compensate for bearing misalignment. The removable seal permits measurement of internal clearance during installation, which is an easy bolt-fastened operation.

Our sealed bearings are also dimensionally interchangeable with conventional spherical roller bearings.

Additional applications include conveyors, crushers, compaction equipment, and ball and sizing mills.

SAF pillow blocks with OLB seals

The SAF-series pillow blocks are engineered to provide robust performance in the most challenging operating conditions.

Manufactured from cast iron – with ductile iron and cast steel options – they withstand substantial mechanical shock, resistance to corrosion, and resilience in extreme temperatures. And with the goal of achieving maximum reliability, uptime and bearing life, they can be optioned with NSK’s OLB seal, an advanced, proprietary sealing solution designed to keep grit and contaminants out, while keeping clean bearing lubrication inside the housing.

Benefits:

• High-performance seal preserves optimum bearing lubrication and prevents ingress of contaminants

• Compact design – no significant increase in assembly width

• Maintenance-free – no grease required

• Longer seal life – non-contact design eliminates wear

• Interchangeable, drop-in solution with no housing modifications required

Additional applications:

• Conveyors

• Crushers

• Compaction equipment

• Pumps

• Headframes

• Ball mills

• Sizing mills

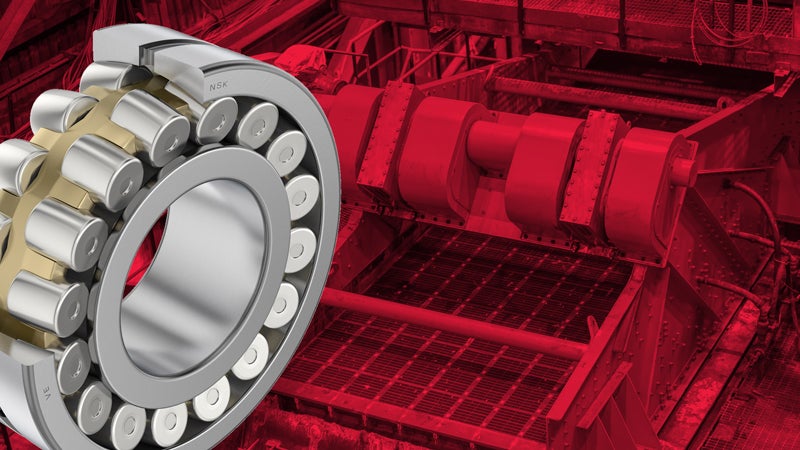

CAM-VS spherical roller bearings

The CAM-VS series of spherical roller bearings has been engineered from the ground up for high-load, high-speed vibrating machinery such as screens and crushers, where heavy shock loads are virtually uninterrupted. They employ high cleanliness steel and precision-machined brass cages with tightly controlled internal clearances and dimensional tolerances, to combat the effects of vibration, operating fatigue, wear and corrosion.

Superior roller guidance and improved surface roughness on the rollers and inner and outer rings reduces damage caused by slippage, flaking and surface fatigue.

Design features:

• Manufactured from high-strength, ultra-clean steel for greater fatigue strength

• Heavy-duty precision-machined one-piece brass cage

• Contoured cage roller pockets for controlling roller skew and optimizing lubrication flow

• Improved raceway surface finish and geometry promotes reduced operating temperature and improved lubrication

Condition-Proven Benefits:

• Substantially longer service life in applications subject to frequent vibration

• High dynamic load ratings

• Highly resistant to heavy or shock loads

• High-speed performance and low operating temperature rise

• Increased roller guidance and smooth running – reduced bearing damage from slippage, surface fatigue, flaking

Highly resistant components for consistent productivity

Productivity and reliability are the linchpins for success in quarrying and mining. If any of this equipment breaks down, there can be serious implications for production. Additionally, the recent trend towards ever-larger equipment means that repair work can become a major undertaking.

NSK customers require bearings that can withstand these severe operating environments – bearings that are tough, long-lasting and offer high reliability. To meet these requirements, NSK fuses the very latest bearing design technologies with its core technologies for materials, lubrication, and analysis. The result: bearings that consistently outlast typical bearings, for longer machine uptime, and bedrock reliability throughout the mine.

• Motors & Pumps:

Cylindrical Roller Bearing

Angular Contact or Deep Groove Ball Bearing

• Gearboxes:

Spherical, Cylindrical, or Tapered Roller Bearing

Angular Contact or Deep Groove Ball Bearing

• Sizing/Compaction Equipment:

Spherical, Cylindrical, or Tapered Roller Bearing

• Centrifuges:

Spherical, Cylindrical, or Tapered Roller Bearing

Angular Contact or Deep Groove Ball Bearing

Case studies

• Mining Conveyor Pulley

ISSUE: Bearing failures due to contamination on head pulley were causing lost production and increased maintenance time

SOLUTION: NSK Tough Steel bearings extended the bearing life to over 6 years (from 18 months)

Documented Cost Savings: $5,050,880

OTHER SUCCESSES:

Application: Coal Mine Head Pulley

2.25x life over standard material

Documented Cost Savings: $3,367,250

• Iron Ore Mine Pulley

ISSUE: An iron ore mine was having contamination issues in their head and tail pulley bearings and was looking to extend their life.

SOLUTION: NSK proposed their Removable Seal Tough Steel Spherical Roller bearings to increase life due to extra protection against contamination while also improving performance through better installation practices.

Documented Cost Savings: $415,146

OTHER SUCCESSES:

Application: Iron Ore Mine Bend Pulley

3x life over standard material

Documented Cost Savings: $177,920

Application: Iron Ore Mine Bend Pulley

3x life over standard material

Documented Cost Savings: $97,130

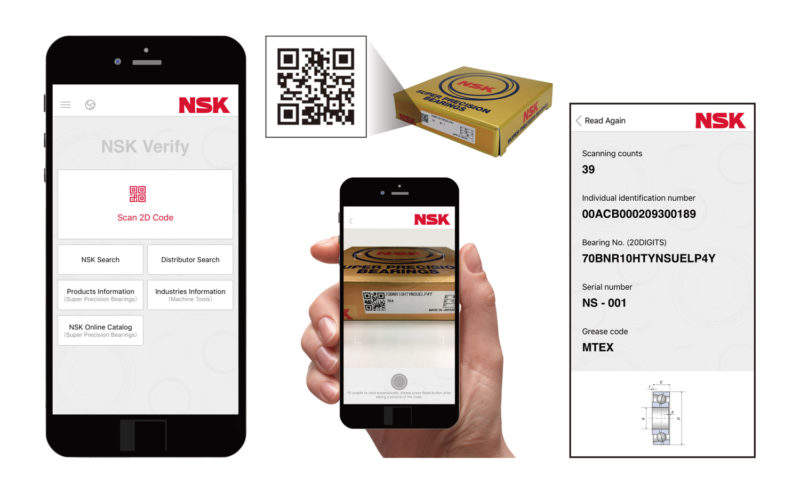

About NSK Americas

For more than 100 years, NSK has been a global pioneer in bearing technology and manufacturing, with a specialization in mine and quarry applications.

NSK field engineers and technicians have worked with facility operators for decades, analyzing the challenges and creating process-specific, condition-proven bearing solutions that deliver exponentially greater production uptime, extended maintenance intervals, and consistently lower operating costs.

For applications where contamination, shock and vibration loads, and poor lubrication can compromise output, NSK bearing solutions have dramatically reduced planned and unplanned maintenance downtime for the most respected producers in the industry.