Mine On-Line Service (MOLS) delivers geochemical analysis services for the exploration, mining and aggregates industries. The analysis is typically performed on-site in real-time with new online technology. MOLS’ grade control services significantly reduce waste rock dilution and ore loss.

MOLS personnel have over 30 years of experience in online analysis methods and have held different posts in major mining and milling equipment providers.

Elemental analysis service

Traditional drill core geochemical analysis requires a great deal of sample handling and transportation with a typical turnaround time from one to three months. To tackle this problem, MOLS have developed Scanmobile, a moving laboratory containing online X-ray fluorescence (XRF) analysis technology. The analysis is performed by fast scanning at the site. Scanmobile utilizes automated scanning for drill cores, drill cuttings and till samples.

Remote access software

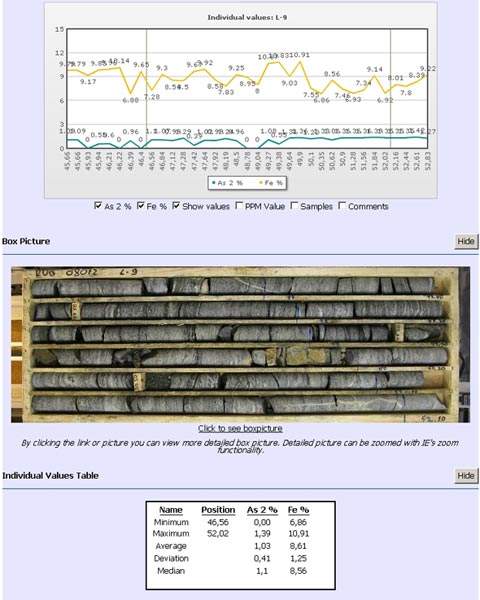

Scanmobile provides instant remote access to databases for results browsing using Remolog™ software. The typical turnaround time for Scanmobile is one to three days from receiving the drill cores to final analysis report.

Remote drill core logging service

Access to drill cores is typically time consuming since they are usually stored in remote locations as well as heavy to handle and set-up for display. Remolog is a drill core logging tool used via the internet. When the drill cores are analyzed in Scanmobile, the geochemical results and high-resolution digital images are stored in the Remolog server.

Using Remolog, the geologist has instant access to drill core analysis data. The results are available before the actual geologist’s logging. Fast Remolog service enables reactive exploration drilling planning.

Grade control sampling and analysis software

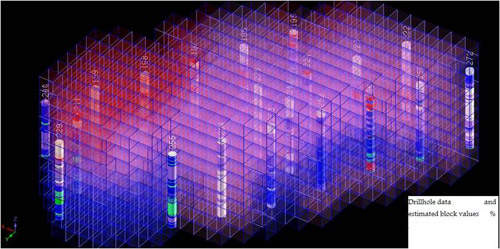

MOLS’ services dedicated to selective mining include patented SoftCore™ for drill cuttings sampling and analysis and further refined blast field block models.

By utilizing MOLS’ selective mining service, selective charging and blasting, selective loading and hauling are now available. The mine now has means to significantly lower ore loss and waste rock dilution.

Blast hole sampler-analyzer technology

As the latest installment to grade control services, MOLS has recently developed blast hole sampler-analyzer (BSA) technology for sampling and analyzing the drill cuttings directly from the drill hole. The integrated analysis system utilizes state-of-the-art online geochemical analyzers from IMA Engineering.

Milling services

The mill throughput in mines can vary significantly, thus resulting to high uncertainty in the general mine economy. MOLS provides mill feed studies by measuring the real content of the crushed ore on a conveyor belt and combining the results with mill performance.

Particle size analysis is conducted simultaneously upon request. The mill feed analysis helps the mine to better understand the ore characteristics that affect the mill’s performance. The analysis results can be used for selective mining to increase mill throughput and for recovery optimization. MOLS also provides fixed analyzer and sampling equipment installations.

Mining application studies

The geology and ore type and grade are different in every mine. Application studies from MOLS are used to find out the right method or a combination of methods for detecting the desired elements, minerals, rock types and/or mineral alteration zones. Application study is usually the first step for further implementation of online analytical methods to the mine.

MOLS holds in-house know-how of different analytical technologies such as XRF, laser induced fluorescence (LIF), reflectance methods (digital images, NIR) and laser-induced breakdown spectroscopy (LIBS).