HK Calibration Technologies (HKCT) offers calibration services and equipment to clients in the mining and minerals industry. HKCT has seven calibration facilities across Australia that provide two-day turnaround services, as well as a team of experienced technicians that offer mobile testing.

Calibration of tools and electrical equipment

HKCT’s calibration procedure adheres to the standards set in BS 7882:2008. The process involves:

- Preload the torque measuring device three times to its maximum applied torque to exercise the device and stabilise it

- Calibrate the device with a minimum of five equal steps from 20% to 100% of maximum torque

- Classe 0.05 and 0.1 items are calibrated in four different mounting positions, each rotated 90º around the measurement axis. All other classes use a minimum of two different mounting positions

- Take two series of readings then disconnect the device from the fixture and rotate it 90º. Then preload it to full-scale and take a third series of readings. This process is repeated until all orientations are recorded

- If reversibility is required, a single series of decreasing torques is applied. If both directions are required, the readings are repeated in the opposite direction

- Analyse data captured to determine the parameters for correction

The company range of calibration services covers:

- Pressure gauges such as pressure switches, pressure transducers, pressure controllers and vacuum gauges

- Gas and fluid flow meters such as air flow meters, level transmitters, rotameters

- Gas monitoring equipment, gas detection instruments, O2 depletion / detection monitors and breath testing equipment

- Electrical instruments and multimeters, volt meters, current transducers and hi-pot testers

- Scales, balances and load cells, as well as certification of scales and balances used for trade

- Thermometers and temperature monitoring devices

- Lab instruments from lab meters to audiometers, safety cabinets, autoclaves and sterilisers

- Metrology / dimensional dial gauges, screw plug gauges and a variety of dimensional measuring instruments

- Bio-medical instruments and occupational therapy equipment

- Flow meter calibration both liquid and gas on-site and in-house

HKCT recommends that entire systems are calibrated at once, and not in separate parts. This is a far quicker solution and avoids units being held at the testing laboratory. Also, component parts must both be calibrated, for example, a transducer and display unit should be calibrated together or their certification will be invalid as the entire loop of operation is not taken into account simplifying the validation procedure.

Torque wrench and ratchet calibration

Regular use causes wrenches and ratchets to wear and come out of correct calibration. Planned maintenance of wrenches and hand tools ensures that they remain accurate, effective and in good condition to reduce the margin for error and poor joins.

HKCT’s technicians assess torque wrenches to verify their accuracy and carry out adjustments where necessary. This is recommended once a year for optimum tool performance, and takes around 48 hours. Calibration work carried out meets all Australian standards, along with an unbroken chain of traceability to National Measurement Institute (NMI).

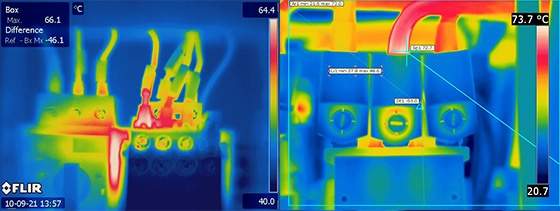

Preventative maintenance through thermal imaging

Thermal imaging is an effective method of performing preventative maintenance, as it enables viewing electrical and mechanical faults, as well as over heating and cold air loss. The cost benefits can be significant, as issues can be diagnosed long before any damage occurs.

HKCT’s qualified technicians provide a thermal imaging service that is economical, accurate with rapid results and non-intrusive, so operations can run as normal during the process.

Onsite calibration testing and planned maintenance

HKCT’s certified technician’s can perform calibration services onsite at a client’s location to ensure their equipment functions correctly at a low cost. Any equipment found to need servicing can be taken to HKCT’s electronic repair laboratory for work.

As well as carrying out the calibration, HKCT also sets-up a testing schedule for each client to ensure all of their equipment is maintained regularly and efficiently, performance to the premier ISO 17025:2005 and ISO 9001:2008 standards.

Measurement instruments, monitors and test equipment

HKCT sells a broad range of equipment for managing environmental conditions.

HKCT supplies gas monitors and gas solutions; high-quality digital test equipment for environmental monitoring; metrology measuring tools and kits; scales and balances; thermometers and indicators; electrical test and measurement instruments in standard, portable and wireless options; pressure gauges and data loggers, vibration analysers, thermal imaging equipment and non-destructive test and measurement equipment.

A selection of calibration measuring and monitoring instruments is also available for hire. The company’s expert team of technicians will assist you in selecting the most suitable tool for your task. Just call or complete an enquiry.

About HK Calibration Technologies

HK Calibration Technologies Pty Ltd is an Australian company that was established in 1992 and today has locations in Sydney, Melbourne, Perth, Brisbane, Adelaide, Hobart and Gladstone.

The Australia-wide locations offer specialised calibration services to large clients such as mining companies, but also meet the needs of small businesses and individuals. This is achieved while being committed to a 48hr turnaround from all of its state-of-the-art facilities across Australia.

HKCT’s strict adherence to internationally recognised SAI global accreditations to ISO 9001:2008 means that all equipment is serviced to fully comply with the demands and standards of the Australian industry.