Valley Rubber offers custom and standard parts, utilizing compression, transfer and injection moulding. We primarily serve the mining and aggregate industries but also provide moulding solutions to a wide variety of customers.

In addition, our engineering division, called Rockland Engineered Solutions, can provide turnkey solutions to end your troubles with sticky material buildup, severe abrasion, plugging, blinding, pegging, spillage, dust containment and much more. Please visit the Rockland website following the link below to find out more.

We manufacture parts that are dimensionally correct, functionally superior and use the best abrasion-resistant additive for rubber. As well as small parts, we can also produce extremely large parts – over 15 times larger than your average rubber moulder. We can customize all of your screening and lining solutions.

Custom molding and credible solutions

Valley Rubber’s parts offer three main advantages, impact absorption, abrasion resistance and noise emission reduction.

Our rubber parts are made to absorb great impact. When the goal is reducing the shock and damaging vibration of severe impact, our rubber maximizes the life of equipment and dramatically reducing your cost-per-ton. The rubber is also well-suited to resisting severe abrasion. In most cases, metal surfaces just can’t compete with rubber for long-term abrasion resistance.

Noise pollution is a key consideration of the environment and for people working on and around job sites, and our parts are proven to reduce noise emission significantly.

Inflatable rubber liners for plugged shoots

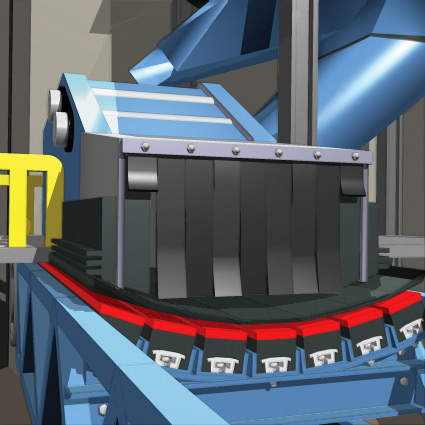

Valley Rubber’s inflatable liners are cost-effective when installed in areas in which there is severe build-up as a result of high moisture content in the material. These systems consist of custom-fit rubber liners that inflate and deflate with low-pressure air supplied through a user-friendly Valley Rubber control box and low-pressure plant air.

The timed action keeps the liners clean and the chute free from build-up. These systems provide extensive periods of maintenance-free service in areas which were previously high maintenance.

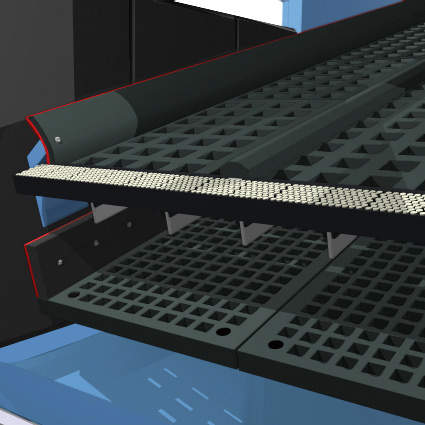

Rubber and ceramic liners for severe abrasion

Rubber and ceramic liners are suitable for applications in areas of severe impact and areas of high abrasion. Liners can be supplied to incorporate a variety of ceramic shapes, including balls, cylinders and cubes, all of which have a high alumina-silica content that withstands severe impact and high abrasion.

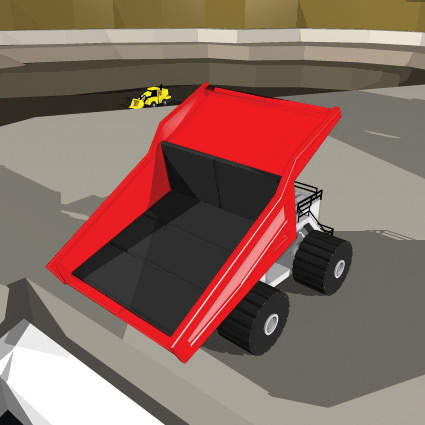

Haultruck liners for mining truck body damage

Valley Rubber manufactures haul-truck bed liners for all size truck bodies and has historically lined 25t up to 360t trucks. We can effectively line heated and non-heated beds, offering extreme abrasion resistance and reducing metal fatigue and stress fractures, while increasing driver comfort and reducing noise. The easy-to-install liner system is cost-effective and maintenance-free compared to steel liners, increasing equipment availability.

Quiet and reliable, our bed liners extend the life of your equipment for the long haul. Their convenient modular design makes for both an easy installation and replacement.

Moulded tapered apertures for plugging and blinding

Moulded tapered apertures dramatically reduce plugging and pegging compared to punched holes.

Valley Rubber screens have moulded tapered apertures, providing you the best technology available on the market today. Round, square, slotted and custom-designed apertures, in a wide variety of sizes, are used to solve screening problems such as blinding, pegging and wear life.