Integrated Global Services (IGS) provides turnkey surface protection solutions for mission critical equipment. Our proprietary High Velocity Thermal Spray (HVTS) cladding and SMARTGard systems solve corrosion and erosion problems in boilers, ducting, baghouses, cooling parts, stacks and ESPs.

Waste Heat Boiler Corrosion

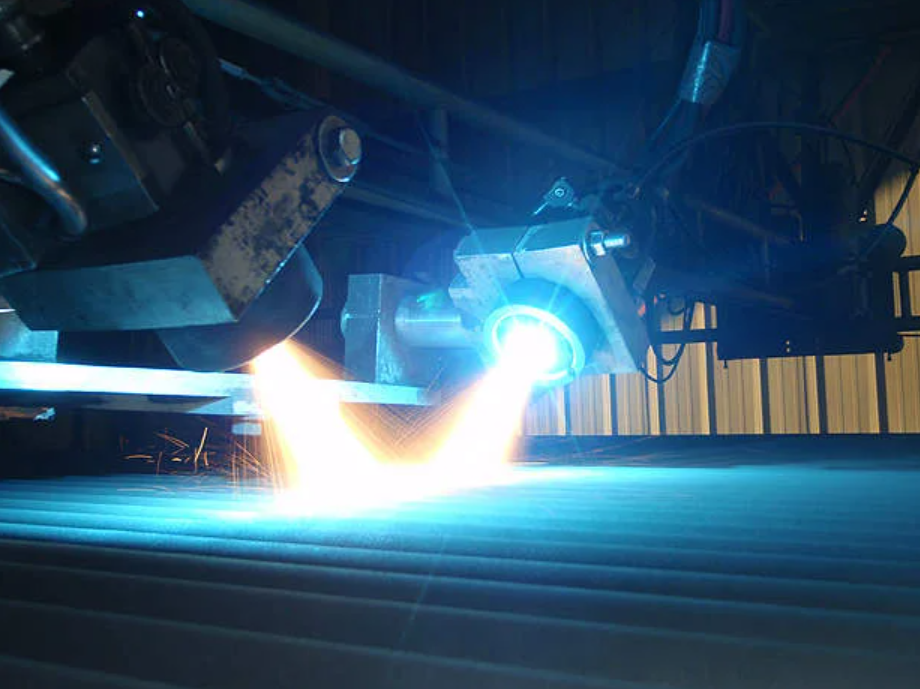

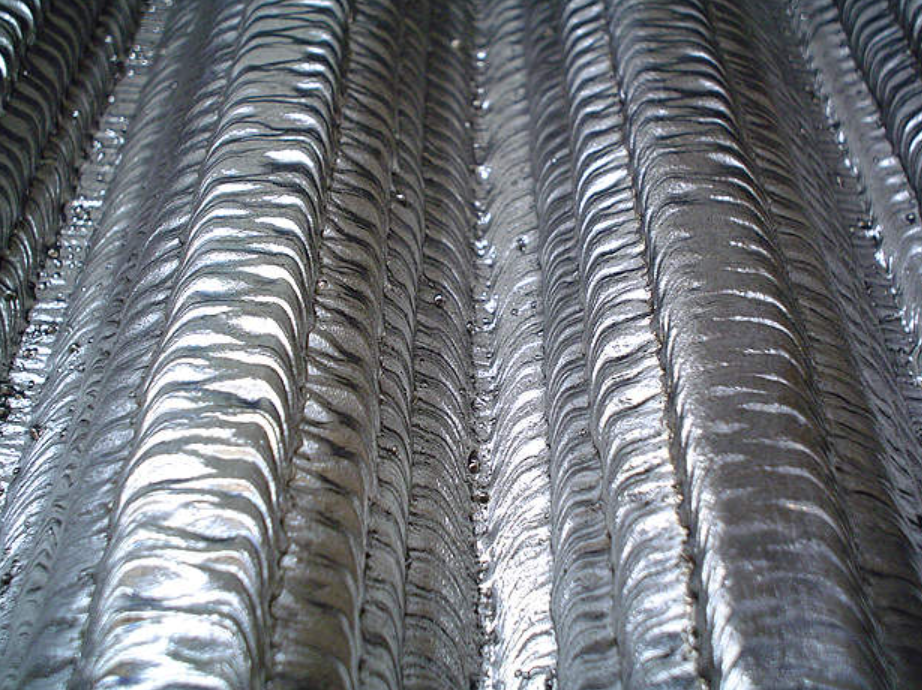

Developed for safe on-site application, IGS HVTS is widely used to permanently stop metal wastage, preventing the need to cut and replace the metal parts or continuously reapply low-performance coatings.

Why IGS?

- Experts in wastage mechanisms

- Decades of global application experience in squeezing turnaround time

- Long-term maintenance programs

- On-going support and advice

- Short payback period, significant long-term ROI

Global metals & mining smelters and refineries benefit from this innovative metal wastage solution in their pyrometallurgical furnaces, waste heat boilers (WHB), baghouses, off-gas ducting, ESPs and stacks.

“IGS have been protecting our waste heat boiler with HVTS since 2015. Their reliable application service has finally stopped corrosion on the waste heat boiler tubes, preventing the need for welding and replacement.” – World’s largest producer of platinum

The Benefits

- Reduces risk in Risk-Based Inspection (RBI) programs

- Improves WHB life

- Prevents unplanned shutdowns

- A fast, reliable, cost-effective solution both to high-temperature and dew-point corrosion

IGS’ SMART Approach to Mission-Critical Equipment Reliability

The IGS SMARTGard approach has been developed across four decades by working closely with hundreds of operators and OEMs. What makes this solution so smart?

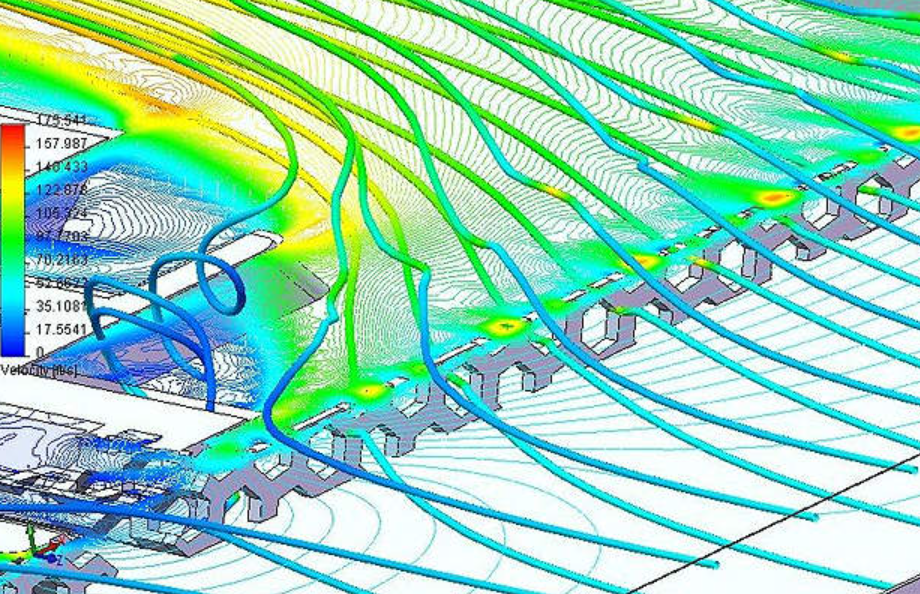

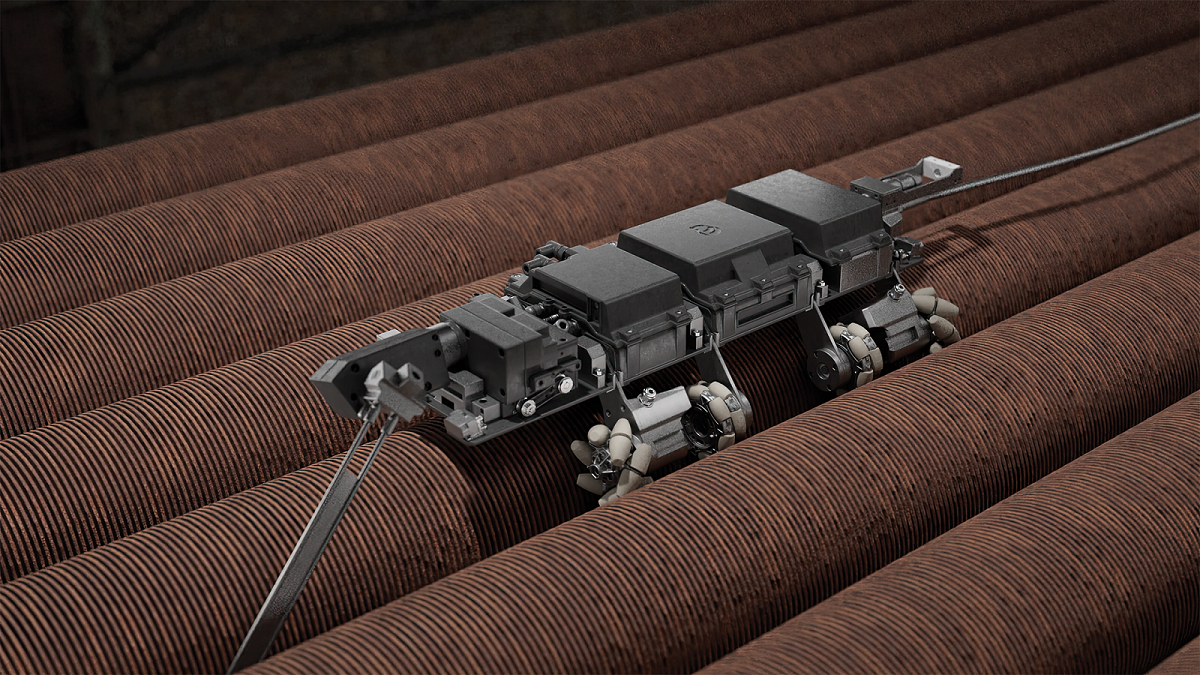

- S stands for systematic. Our service starts with a comprehensive metal wastage assessment and considers all operational aspects of the asset. We investigate the surface conditions thoroughly with our eyes, drones, lasers and AI.

- M stands for materials and equipment. IGS has developed proprietary equipment and alloys designed for field protection against high-temperature erosion and corrosion environments. Our cladding system works where all others fail.

- A is for application by trained and certified teams. Our experienced technicians, stationed in 15 countries, perform more than 200 days per year on shutdown and turnaround projects. No matter what your turnaround schedule is, our teams make it happen. We are proud to say that our customer satisfaction score for site execution and schedule adherence is 4.8 out of 5, surveying 113 customers.

- R is for results that are measured, documented and monitored. IGS maintains detailed records of all quality and completion documentation, initial inspection reports and all cladding thickness maps for 3000+ projects completed. Since 2019, we have scored 4.85 out of 5 for quality commitment, surveying 226 customers.

- T is for testimonials that prove performance. “IGS has been protecting our waste heat boiler with HVTS since 2015. Their reliable application service has finally stopped corrosion on the waste heat boiler tubes, preventing the need for welding and replacement.”, – World’s largest producer of platinum