Nalco is a world leader in the fields of mining, minerals processing and water treatment. The company provides the mining and minerals industry with on-site expertise and technically, economically, and environmentally sustainable solutions from mine-to-mill.

The mineral processing industry is constantly challenged to improve profitability, efficiency, product quality, and environmental performance. Nalco combines global leadership, years of industry experience, innovative technologies and local expertise to deliver high impact results.

Nalco has partnered with mineral processors worldwide to develop reliable, cost-effective and safe solutions to their most pressing challenges. Our aim is to deliver a measurable return on investment (ROI) through our range of chemical programs and services offered to the following industry segments:

- Alumina

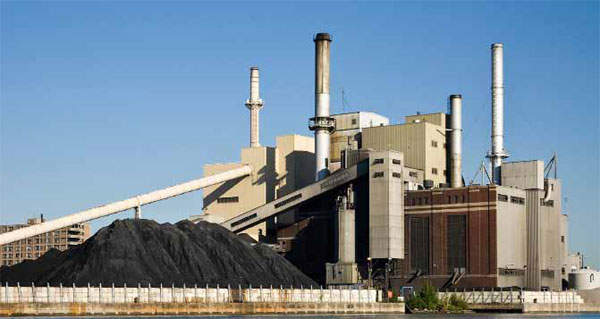

- Coal

- Copper, molybdenum, nickel, lead, and zinc

- Gold, silver, and platinum

- Industrial minerals

- Iron ore

- Phosphate and potash

- Sand, gravel and aggregate

Nalco’s highly-trained sales engineers help our customers achieve their goals by selecting and implementing optimal process and water treatment technologies to increase recoveries and improve finished product quality, while optimizing the total cost of operation.

Water treatment solutions for mining and mineral processing

Water availability and quality plays a critical role in virtually all mining and mineral processing activities and 80 years of experience makes Nalco one of the world’s leading providers of water treatment, supply, and re-use. The company serves nearly 50,000 customer sites in 150 countries across the globe.

Mineral processors now require solutions that demonstrate sustainable ongoing water management. Nalco’s mining and process technologies and application expertise, coupled with our core water treatment knowledge, make us the perfect partner to assist with all aspects of improved sustainable water use.

Integrated chemical solutions for the mining and mineral processing industry

Nalco’s Research and Development efforts have resulted in numerous modifications and improvements to our offering over the past several years. Innovation is a key part of our customers’ success and our growth, so we are continuously searching for:

A. New chemistries which will deliver improved performance and value for our customers

B. Modifications to existing products to enhance performance in the customer’s process

C. Completely new applications for existing products

D. New chemistries that reduce or eliminate environmental impacts

Among the main areas of progress and innovation that Nalco has focused on in mineral processing are:

- Coal Flotation Collectors – alternatives to diesel fuel that reduce environmental impacts

- Fertilizer Coatings — Environmentally-friendly products for improved dust control and anticaking

- Scale Inhibitors – improved performance on sulphate scale control

- Automation Systems — monitoring system performance and chemical program control

- Sulfide Flotation Collectors – improved selectivity against Fe minerals and increased molybdenum recovery

- Flocculant Technology — products that enhance the settling of red mud and products that invert more rapidly

- Mine Water Treatment – more efficient and selective removal of heavy metals

- New and more effective dust control additives for haul roads, crushers, and stockpiles to improve working conditions and protect the air and surrounding communities near mining and ship loading operations.

Nalco has introduced several new programs and innovations, including:

- POL-E-Z® Liquid Flocculants-quick inverting flocculant technology

- Pinnacle® Sulfide Flotation Collectors – improved Cu and Mo recoveries and better selectivity

- PERFLOW Fertilizer Coatings – cleaner and greener products for caking and dust control

- NALFLOTE® Coal Collectors – diesel fuel alternatives to increase fine coal recovery

- RRA® (Rigid Rod Architecture) Flocculants – increased red mud underflow densities, improved overflow liquor filterability and reduced scaling

- OreBind® Tailings Management Technology – increased water recovery

- DustFoam Plus and DustBind Plus technologies for in-plant and in-transit fugitive dust control

A key consideration for identifying the best Nalco program is what will deliver the lowest total cost of operation (TCO). This involves the cost performance for the entire program, and not just the chemical cost. Optimization of a program is accomplished through a detailed evaluation by the Nalco service engineer to understand the process and objectives of the customer, and then to select the right product, apply it at the best location(s) at the right dosage, and then monitor the program on a regular basis to ensure that it is operating at optimum performance and that our customers "hold the gains". As the ore characteristics or process conditions change, it may be necessary to modify the dosage or even change to a different product.