BACHILLER Barcelona is an industrial engineering company that specialises in the design and construction of process equipment for the mining, chemical, fine chemical and pharmaceutical industries.

The company offers a wide range of high-quality equipment and solutions for very diverse processes such as pressure filtration (Nutsche filters) and vacuum drying for adverse environments.

With BACHILLER Barcelona’s engineering department and test laboratory, the company collaborates with clients developing customised solutions and new processes. Combined with the company research and development department, it is constantly developing solutions to improve performance.

Agitated filter dryers for solid-liquid separation processes

The Nutsche Filter (FNB) and the Nutsche Filter Dryer (FNB-S) by Bachiller are high-quality pieces of equipment designed for solid-liquid separation processes, by filtration under pressure, for the mining, chemical, fine chemical and pharmaceutical industries.

BACHILLER Barcelona’s Nutsche filters and vacuum dryers can be made in a high range of materials such as austenitic and super-austenitic steel, duplex and super duplex, Hastelloy and all grade of nickel alloys, as well as all titanium grades, in order to give the best solution possible to the process requested.

The dryer version enables the drying of the filter cake without product transfer to other equipment, making it suitable for all those processes that are more desirably treated in hermetic equipment, due to the special hazardous or toxic characteristics of the products, or simply to prevent cross-contamination.

Vacuum dryers for the mining industry

BACHILLER Barcelona designs and manufactures a large range of vacuum dryers to provide the most appropriate solution for each type of process.

The company’s vacuum dryers have been specially designed in response to these needs, which are proper to the mining, chemical, fine chemical, pharmaceutical industries, and guarantee the product is dried and respected.

Vertical ribbon vacuum dryers

The Supramix-S (MVC-S) is a vertical ribbon vacuum dryer with a maximised heating surface for the drying of all types of thermo-sensitive wet, crystalline, amorphous or paste products, with a total vacuum.

The Supramix-S comprises a heated vertical mixing spiral, rotating at a moderate speed to achieve an upward flow of perimeter product and a constant renewal of the product in contact with the heated walls.

Horizontal vacuum paddle dryers and reactors

The Turbodry (MHT-RS) is a horizontal vacuum paddle dryer and reactor designed for products with pseudo-plastic behaviour during the reaction and/or drying phase, where the product needs to be agitated with high torque and turbulence.

With the body and shaft completely heated to maximise thermal exchange and the paddles rotating at very high speed near the wall, the Turbodry causes high turbulence in the product and its continuous renewal in direct thermal exchange with the wall, enhancing that way the drying process.

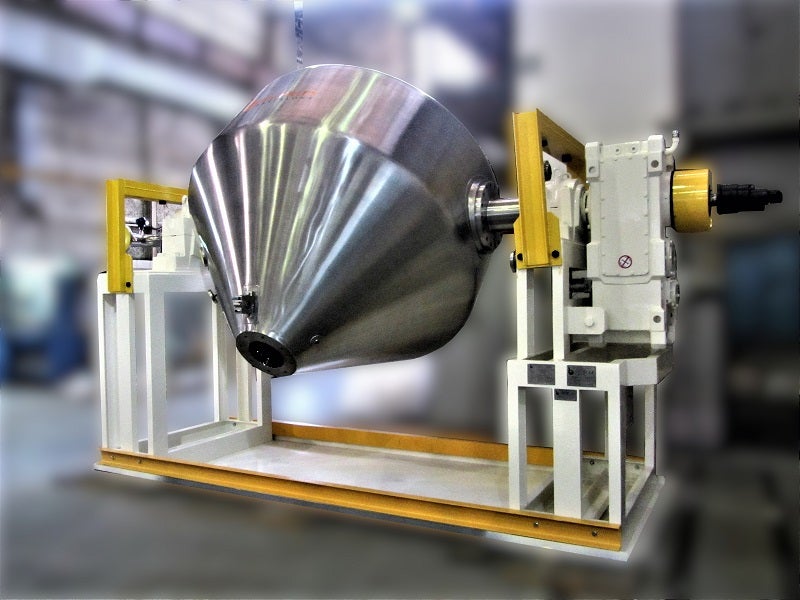

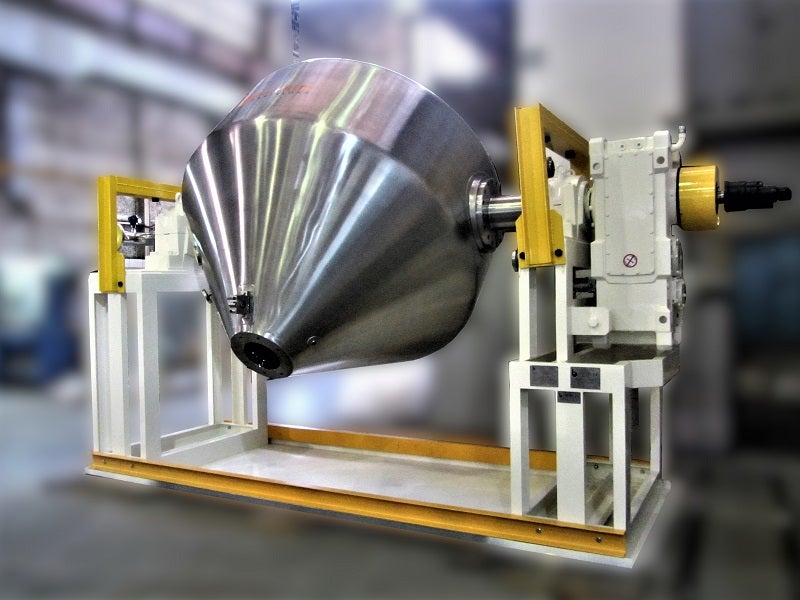

Double cone vacuum dryers for thermo-sensitive products

The Bicuum (MBC-S) by Bachiller is a double cone rotary vacuum dryer, suitable for ultra-vacuum drying of all types of moist, crystalline and amorphous thermo-sensitive products.

The Bicuum consists of a fully heated and insulated drum, which rotates at low speeds while being subjected to a strong vacuum, which continuously renews the product in contact with the hot walls with a very gentle product movement.

Horizontal vacuum paddle dryers

The Paddledry (MHT-S) is a highly efficient horizontal dryer, specially designed for products with pseudo-plastic behaviour during the drying phase, with high torque requirements.

The principle of the Paddledry is its operation through a body, shaft and blades, which is fully heated to optimise heat exchange with its blades rotating very close to the wall at low speed for continuous renewal of the product in direct exchange with the wall.

Vertical conical screw vacuum dryers

The Conical (MCV-S) vertical conical screw vacuum dryer has a sanitary design, with a maximised heating surface, for the drying of all kinds of moist thermo-sensitive, crystalline, amorphous or paste products.

The MCV-S comprises a fully conical vertical vessel, with a vertical screw mixing system, procuring a gentle mechanical treatment to the product, and ensuring a very reliable unloading capacity.

International certifications and quality assurance

BACHILLER Barcelona designs and manufactures solutions in-house, as well as oversees the entire manufacturing process, from the calculation and design, steel construction and welding procedures, machining, polishing, explosion and inflammability proof, high-pressure proof, vacuum tightness, up to the factory acceptance test (FAT) and installation qualification (IQ) protocols performance.

The company also provides on-site service from assembly supervision to start-up and training, going through commissioning, SAT performance, training on equipment and process performance operations.

BACHILLER Barcelona has the quality certifications ISO 9001: 2008, U and U2 seal of ASME, HP0 certificate according to AD-2000 Merkblätt, Module H1, according to PED and A2 licence according to SQL of the People’s Republic of China.

All equipment can also be supplied with official explosive atmosphere (ATEX) certification for category 1 (0/20 zone).