Mine Environment Management (MEM) is a specialised technical geoscience consulting company that focuses on developing and delivering innovative solutions for the sustainable environmental management of mine sites and related waste.

Applied geoscience for effective mine site environmental management

MEM is experienced in the environmental management of tailings and waste rock storage facilities across a wide range of geographical locations, climatic site settings, and commodity types.

Implementing a shared passion for geoscience, the environment, and geology, we operate across the full life of mine cycle from newly discovered deposits through to closed legacy sites.

Integrated mine closure planning

MEM believes that the finalisation of mining activities can provide an opportunity for a new positive purpose for the site. We are enthusiastic in our approach to post-mining repurposing and rehabilitation that aims to establish a positive legacy of mining activities and a successful transition to a new application.

We have significant experience of progressive closure planning and concepts and understand that progressive closure strategies are integral to successful long-term risk management. Our capabilities are customised to meet the requirements and conditions of the mine site.

Our technical support services for mine site rehabilitation and repurposing applications include:

- Tailings and waste rock storage facility concept design and AMD mitigation assessment

- Carbon capture and sequestration potential assessment

- Environmental monitoring and sampling plans

- Novel repurposing project feasibility assessments

- Progressive closure planning and concept designs

- Waste placement concept design

- Rehabilitation concept design and planning

- Oxygen ingress control engineering concepts

- Source evaluations for rehabilitation materials

- Waste materials scheduling and balances for rehabilitation

Mine Site Geochemistry, Waste Characterisation & Predictive Modelling

A number of the world’s largest engineering projects comprise mine waste facilities and can pose significant long-term site management risks.

Our approach enables integrated, sustainable and innovative planning to successfully manage long-term environmental risks. Our technical team are experienced in the assessment, design and management of tailings and waste rock storage facilities worldwide in climates from the arctic to the tropics.

We offer a range of support services for the environmental management for tailings and waste rock such as:

- Acid and metalliferous drainage assessments

- Spontaneous combustion assessment

- Predictive geochemical modelling

- Waste rock and tailings classification

- Hydrogeochemistry

- Groundwater and surface water fate and transport modelling and quantitative risk assessment

- Site investigations and waste storage facility risk assessments

- Environmental impact assessment

- Gas flux or seepage assessment and modelling

- Mine waste management plans

- Validation testing programs and method statements

- On-site testing and analysis programmes

- Monitoring system design

- Telemetry and data logging systems

- Acid sulfate soils assessment

Innovative geochemical laboratory analysis and R&D

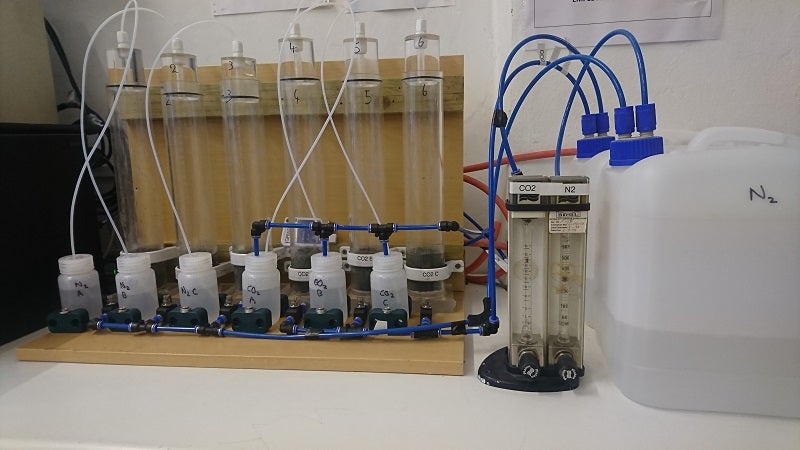

MEM offers a vertically integrated service offering, where the company designs, manages and controls the geochemical testing process from site sampling through the laboratory and to data analysis.

We understand that laboratory data provides the scientific basis for the majority of technical studies related to environmental management. We believe in a first-principles scientific approach as no site is the same and as such our guiding principle is to be specialised and not generalised. To deliver our integrated services we are partnered with a specialised geochemistry laboratory whose facilities offer innovative and customised laboratory testing services in the area of geochemistry and waste characterisation.

We support and actively engage in world-leading research and development in the areas of mine site geochemistry, mine waste management and water treatment. Our close partnerships with academia, industry and laboratories allow us access to leading facilities and researchers.

We offer a range of support services for research and development and laboratory testing to include:

- Laboratory testing program design, management and cost control

- Oxygen consumption testing design and operation

- Leaching column design and operation

- Kinetic testing design, set up and operation (HTC, LC)

- Static geochemical analysis

- Mineralogical analysis and interpretation (SEM, XRD)

- Particle size-specific geochemical analysis (PSSGA)

- Customised and modified analysis techniques

- On-site field testing (FPXRF)

- On-site laboratory testing specification and installation

Integrated Mine Waste Modelling, Planning, Scheduling & Operational Management Optimisation

When exploration drill rigs start turning to the rehabilitation of the site, geochemistry underpins critical decision making and planning for many aspects of a mining project.

MEM believes that geochemistry assessments should be integrated as a cross-discipline and life of mine activity. We are experienced in working with operational site teams and our principles are based on the demands of modern mine operations. Mine planning is central to the achievement of great outcomes and we recognise the balance between meeting short term production goals, and long term planning to minimise risk. As such we aim to adopt a consistent pragmatic and practical approach.

Our mine waste modelling, planning and operational optimisation services include:

- Development and optimisation of waste schedules

- Linking waste schedules with build plans and conceptual engineering design

- Waste block model development and reconciliation assessment

- Drilling program design for geochemical sampling programs

- Waste grade control and reconciliation program development

- AMD and waste management plans and manuals

- Fragmentation assessment

- Instrumentation and monitoring system design

- Life of mine materials balance development

- Site operational procedures and manuals

- Workshops and training

- Third-party technical review

- Site laboratory testing set up and geochemical analysis QA/QC

- On-site establishment of kinetic testing programs

Mine water treatment assessment and innovative technologies

MEM understands that water treatment is often required to support site operations as part of environmental management. In addition, it may be the only practical option to effectively manage many legacy sites.

We focus on supporting the development and implementation of innovative and sustainable water treatment technologies such as sono-electrical water treatment systems being developed in Wales.

Our technical support services in the field of water treatment includes geochemical analysis and assessment; hydrogeochemistry; principal component, options appraisal and cost-benefit analysis; concept engineering design; and laboratory treatment studies and trials.