Railroad Friction Products Corporation (RFPC), a partner company of Wabtec Corporation, manufactures COBRA® high-friction and low-friction composition brake shoes, specialty shoes, and disc brake linings for freight, locomotive and transit vehicles.

High-friction and low-friction composition brake shoes

COBRA high-friction, low-friction and TreadGuard® composition brake shoes are designed to meet the individual friction requirements of your equipment and brake systems.

COBRA brake shoes vary in design and target specific areas that can reduce or eliminate expensive operational and maintenance issues. Low-friction composition brake shoes serve as a direct replacement for cast iron shoes.

TreadGuard brake shoes were designed to address wheel removals due to shelling, spalling and high impacts.COBRA brake shoes provide distinct benefits for a wide range of freight car and locomotive applications.

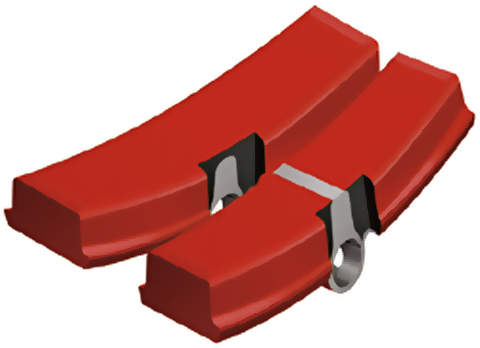

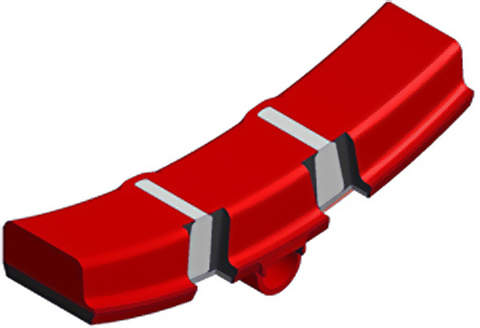

Brake shoes for high-capacity mining applications

The COBRA TreadGuard brake shoes we manufacture have been proven as an effective method to increase wheel life for over a decade.The newly introduced COBRA TreadGuard HiCap brake shoes offers the unique benefits of the traditional TreadGuard shoe, but are now built especially for high-capacity applications.

Designed for today’s heavier cars with higher net braking ratios, TreadGuard HiCap maintains a cool temperature, plus improved resistance to brake fade. Field tests have proven that COBRA TreadGuard brake shoes can minimize wheel removals due to shelled tread, out-of-round conditions, wheel bearing failures and high impacts.

Dynamometer tests demonstrate that TreadGuard HiCap brake shoes maintain their friction level, while standard brake shoes may fade, under M-997 heavy grade conditions. These benefits could save your company time and money.

Low-friction locomotive brake shoes

COBRA low-friction locomotive brake shoes are made with a composition material that is a direct replacement for cast iron. These materials are designed to provide superior stopping performance, and efficient smooth stops, reducing wheel damage caused by over aggressive cast iron materials.

Friction wear liners for mine vehicle transit

RFPC applies friction materials to truck wedges to help control and eliminate abnormal shifting of the railcar in transit subsequently damaging the load. This is particularly necessary in the movement of railcars that are transporting critical and sensitive consumer goods.

The types of cars these products are prevalent on are auto-racks, electronic consumer goods, and other ride-sensitive products. Another benefit of this product is the reduction of abnormal wear on the truck wear plates.

Disc pads for pneumatic and hydraulic mining applications

COBRA disc pads are available for pneumatic and hydraulic applications. They are manufactured in various sizes and shapes that are designed to fit your braking system.

A broad selection of friction materials enable RFPC to meet the specific braking requirements established for your equipment. Newly developed friction materials have increased disc pad and disc rotor wear life while maintaining the required braking requirements.