In today’s competitive world where you need to maximize your return on invested capital, innovative engineering and software solutions for automation, data management and machine design are the keys to driving improvement in operational equipment effectiveness (OEE).

Engineering for OEE

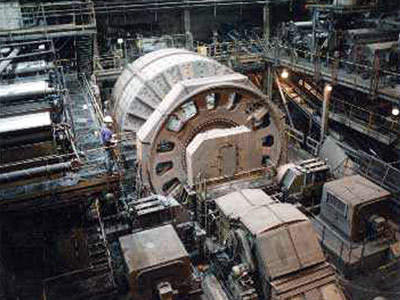

ADM delivers engineered solutions that provide real gains in plant asset availability, performance and product quality. From preliminary design to commissioning, ADM is committed to exceeding our clients’ expectations as we execute mining projects around the world. Our services include:

- Project management

- Preliminary design

- Detailed design

- PLC, HMI and data historian applications

- Energy management information system design

- Services during construction

- Commissioning

- Supplementary services

Automation, data management and mechanical engineering services

ADM has completed automation, data management and mechanical engineering projects for global mining operations.

Real-time, downtime, uptime and event-tracking software

ADM is the maker of the RtDuet™ software and its energy module, RtEMIS. RtDuet, a knowledge-based product, is an automated, real time, downtime, uptime and event-tracking software system.

Traditionally recording, classifying and understanding downtime is not a straight forward activity. In many cases, the difficult task of capturing downtime data is left to control room staff, whose priority is to keep the plant operational rather than performing data-entry duties. As a result, downtime data is often incomplete or inaccurate. This may lead to downtime-tracking efforts being abandoned.

Downtime-tracking for plant equipment

Automating the downtime accounting process is necessary to improve performance. Automating allows the facility to:

- Capture the exact number and duration of downtime incidents

- Assign the “real world” context; the equipment that failed, the problem it had and root cause for that problem

- Categorize and report downtime and root cause

- Enhance maintenance and capital planning to reduce downtime interruptions and eliminate preventable costs

The return on investment for an RtDuet project is often 200%-300% with a payback period of less than six months.

Downtime-tracking plant projects

ADM has completed downtime projects with RtDuet in plants all over the world. With industry-specific knowledge, we can work with your stakeholder group to prepare functional and detailed specifications, machine center definitions and KPI reporting requirements. From pilot project to corporate rollout, ADM is a strong resource who can efficiently execute each phase of the project.

Energy management information software

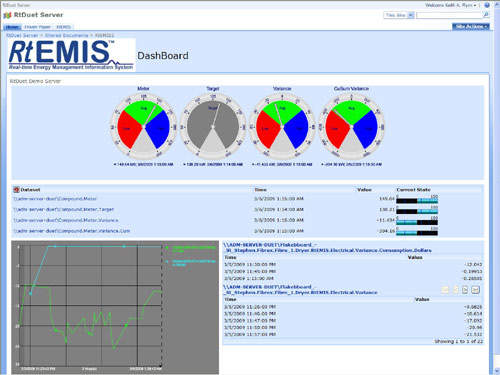

RtEMIS™ is an automated, real-time, energy management information system (EMIS); an add-on module for the RtDuet suite.

ADM can provide engineering resources for each stage of the EMIS project. From auditing and planning to implementation, ADM can provide expertise to define requirements and deliver a licensed software solution to perform the following:

- Measure energy input at key stages of process

- Measure the useful outputs of the process such as production

- Measure the other influencing factors including environmental factors such as temperature or relative humidity

Energy management information system for predicted energy consumptions

By deriving a relationship based on historic performance and using it to predict expected energy or target consumption, RtEMIS can compare targets against actual results, creating energy events and related KPIs for reporting.

Using a real-time energy dashboard, users can drive the real-time results to plant operators, allowing them to manage their energy consumption at a department or operational level.

Energy and resource-saving EMIS software

The benefits of using the EMIS software include energy and resource savings, a 3%-10% reduction in usage costs with rapid payback and minimum capital investment.

In addition, productivity improvements are realized and quickly identified as best practice and disseminated. Historic “ways of working” are challenged and improvements are sustained for the long run.

Energy management information software experience

ADM is currently working to install the RtEMIS software system at Flakeboard’s St Stephen, NB plant and will expand the system to all of its facilities in North America. The system at the St. Stephen site is expected to be fully operational by September 2009. It will allow the company to set and manage adjustable targets for all sources of energy used at the facilities, including electricity, oil, natural gas, bio-fuel and water.