Finsa Filtros was founded more than 30 years ago to provide solutions to the filter media market for all dry and wet filtration processes. Finsa has its own weaving plant and manufacturing department equipped with the latest generation looms, quality control machinery and rolls packaging prepared to produce ready-made cloths. Our wide range of standard products is produced in materials such as polypropylene, polyamide, polyester and other special fibres. The types of yarn we use include monofilament, multifilament and staple fibre.

Our philosophy is based on the ongoing development of new products. Finsa is certified under ISO 9001:2000. In our R&D department, we have a filtration laboratory where we simulate the filtration always based on the information we get through the liquid questionnaire.

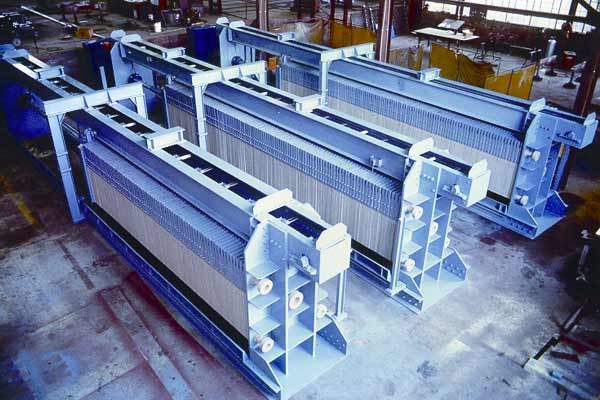

Cloths for filter presses

Double cloths with standard, rubber or reinforced neck or drape over can be supplied according to the customer’s requirements, with or without side holes and with eyelets or velcro to attach them to all kinds of plates chambers or membranes. We study the application to provide the most suitable cloth for the product in order to reduce overall filtration cost.

Horizontal belt filters

Belts made of PP, PES and PA single or double layer are available in different widths and joining systems such as a stainless-steel clipper with over – under lapping to reduce product loss. Edges can coated with special neoprene.

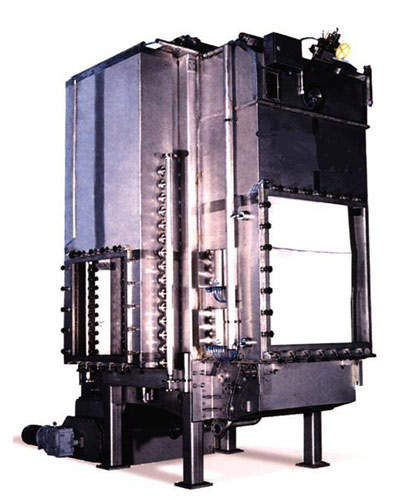

Tower press belts

We can supply belts at the standard widths of 1.05 and 1.70 with coated edges and a clipper resin seam. We have several, different filter cloth types at different air permeabilities depending on the product.

Belts for filter presses

Finsa also sells more than 15 types of belts for filter presses, with different drainage capacities. The company’s belts are suitable for a wide range of applications at any width. We install the clipper seam with resin to assure long product life. Edges can be specially coated.

Fabrics for vacuum filters

Fabrics and belts are available for all types of vacuum filters, including:

- Rotating drums

- Rotating drum band

- Disc filter

- Pan filters

- Tilting pan filter

Filter bags

We can produce any filter bag with any length and diameter. Needlefelts used by Finsa have one face treated, allowing for better dust cleaning by shaking or air-pulsing. Special options are available for high temperatures, hydrolysing and chemical resistant applications, as well as those equipped with PTFE membranes.