Motion Metrics™ products offer particle size analysis products for shovels, loaders, conveyor belts, haul trucks and in a portable format that neither interrupts production nor requires reference scaling objects.

Our monitoring systems for shovels, loaders and haul trucks improve worker safety and equipment productivity. We offer missing tooth detection, tooth wear monitoring, particle size analysis, volume monitoring and boulder detection.

Data from all installed Motion Metrics™ products can be managed through our secure and centralized data analysis platform. Authorised users can access status updates and data summaries, in-depth performance reports, equipment activity logs and particle size data from anywhere.

Motion Metrics™ products include ShovelMetrics™, LoaderMetrics™, BeltMetrics™, TruckMetrics™ and PortaMetrics™. These systems work together as an ecosystem for mines integrating key data solutions to create a detailed view of mining productivity and efficiency while increasing safety and decreasing operational downtime.

Motion Metrics™ products

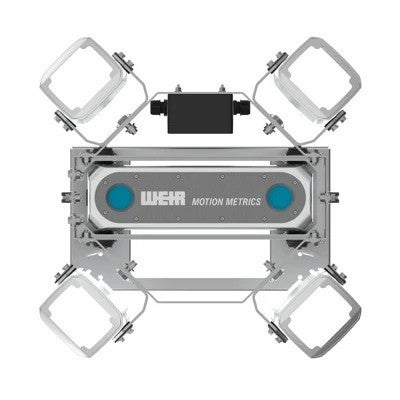

Motion Metrics™ BeltMetrics™

Easy and accurate 3D analysis of the material transported by conveyor belts.

Motion Metrics™ LoaderMetrics™

Mitigate production loss caused by tooth breakage.

Motion Metrics™ PortaMetrics™

Provides handheld particle size analysis without scaling objects.

Motion Metrics™ ShovelMetrics™

A complete bucket monitoring solution for all shovels and excavators.

Motion Metrics™ TruckMetrics™

Monitor each truck on its way to the crusher.