PROK is the world’s leading manufacturer of quality conveyor components within the bulk materials handling industry. Our key business strengths are that we specialise solely in conveyor components and we are constantly advancing innovation within this field.

Our expertise in engineering ensures high-performance, cost-effective, and sustainable solutions for all our customers, providing them with state-of-the-art custom and refurbished pulleys, rollers, idlers, and belt conveyor accessories.

We have manufacturing facilities located across the globe, including our newest facilities in Vancouver, BC and Salt Lake City, Utah. This means that our customers get the technical support and the products they need, when they need it. Our main priority is making our customers successful.

Pulleys, rollers, idlers, and belt conveyor accessories for the mining industry

We manufacture a wide range of belt conveyor products including pulleys, rollers, idlers and belt conveyor accessories that deliver superior outcomes on site to ensure uninterrupted operation of our customers’ systems. We know the importance of keeping material moving reliably and at the lowest possible cost.

Each of our engineered pulleys is designed by our industry leading design software to infinite fatigue life criteria and then is manufactured in our facilities to the most rigorous standards. Final quality is ensured by intense testing and inspection.

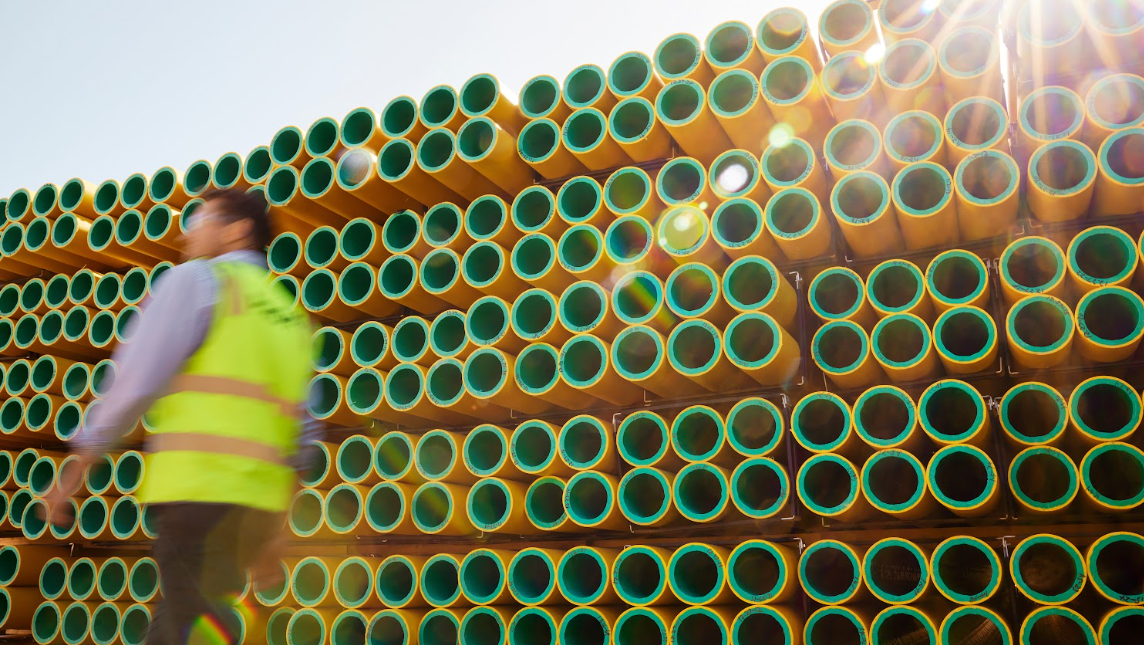

We manufacture an extensive range of conveyor idlers including various types of rollers and complete idler sets. Our innovative designs are focused on lightweight rollers with a long life and low noise performance. We understand the cost of downtime to our customers due to unexpected breakdowns. So, we have incorporated solutions in all facets of our products, specifically shown in our first of its’ kind PROK HDPE roller with visual wear indication.

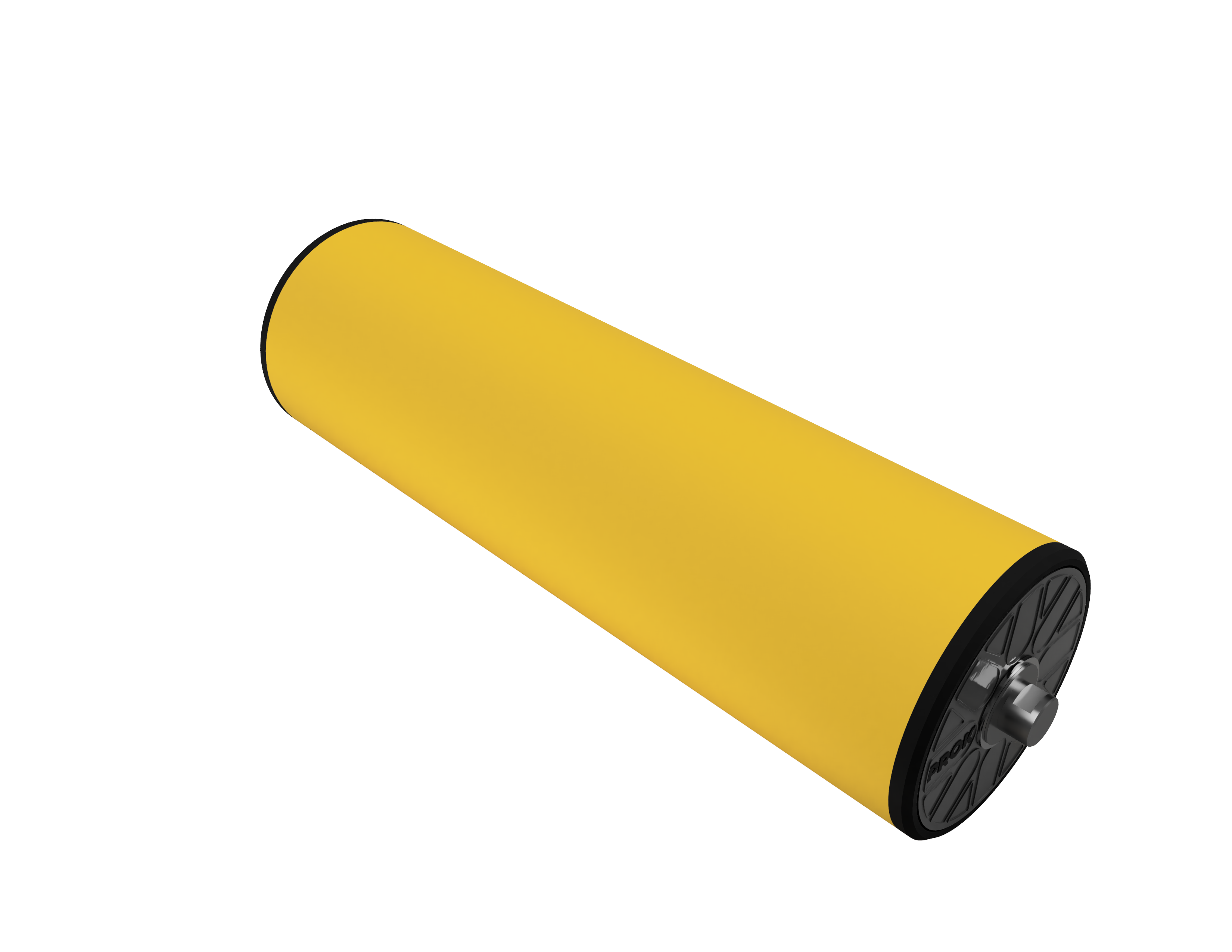

World’s first and only composite roller with visual wear indicators

Like our tagline “Innovation at work,” we pride ourselves on innovation. We have developed a top-notch research and development team that explores new technologies and solutions to improve our products. This dedication is strongly evident in our state-of-the-art HDPE roller – the first and only composite roller with visual wear indicators.

The roller is constructed from a fiber reinforced HDPE tube and friction welded housings that contain low friction multi-labyrinth contact seals with a stainless-steel contact face. The result is a lightweight, easy to maintain roller with superior reliability and performance in high speeds and large tonnage applications.

The unique feature exclusive to the PROK HDPE roller is the wear indicator technology built into the roller tube. The original PROK yellow tube contains a green inner layer which provides visual wear indication, signaling the end of the rollers’ lifecycle. This allows for planned replacement, eliminating downtime due to unexpected failures and damage to the belt, thus ensuring the continuous and safe operation of the conveyor system.

Pulley restoration and refurbishment services

Designed for infinite fatigue life, PROK pulleys are built to last, but like all equipment they wear over time.

PROK facilities and people have the skills, equipment, materials, and components to refurbish pulleys in need of maintenance and bring them to “like new” condition at a fraction of the cost and at a much faster speed than purchasing a completely new pulley.

We repair and inspect all pulley components that can be salvaged and we replace those that cannot with genuine OEM parts. A meticulous final inspection is performed, including vibration analysis, before the pulley is cleared for service.

Our two facilities in North America specialize in idlers and pulleys

PROK currently has two facilities within North America, one in Surrey, BC, Canada, and the other in Salt Lake City, Utah, USA.

PROK Canada specializes in pulley manufacturing, refurbishment, and testing, while PROK USA specializes in conveyor idler manufacturing. Both facilities are backed by PROK’s global engineering and technical support teams. These facilities ensure fast turnarounds on new equipment and the best possible customer service and support.

If you operate belt conveyors, PROK can help. Please contact us by clicking the “make an enquiry” button at the top of the page to find out more about our products and services.