We offer customized agitator solutions for atmospherically gassed mining tanks that impress with their efficiency and cost savings. Our innovative agitator and mixer gassing concepts enable considerable savings in terms of compressor performance, among other things, which in many cases can lead to savings on entire compressors. This not only considerably reduces the investment costs of the overall system, but also significantly lowers ongoing operating and energy costs.

From our wide range of gassing agitators, we can always offer the optimum and most efficient solution, specially adapted to the required gas quantities, the suspension challenges and at economical prices.

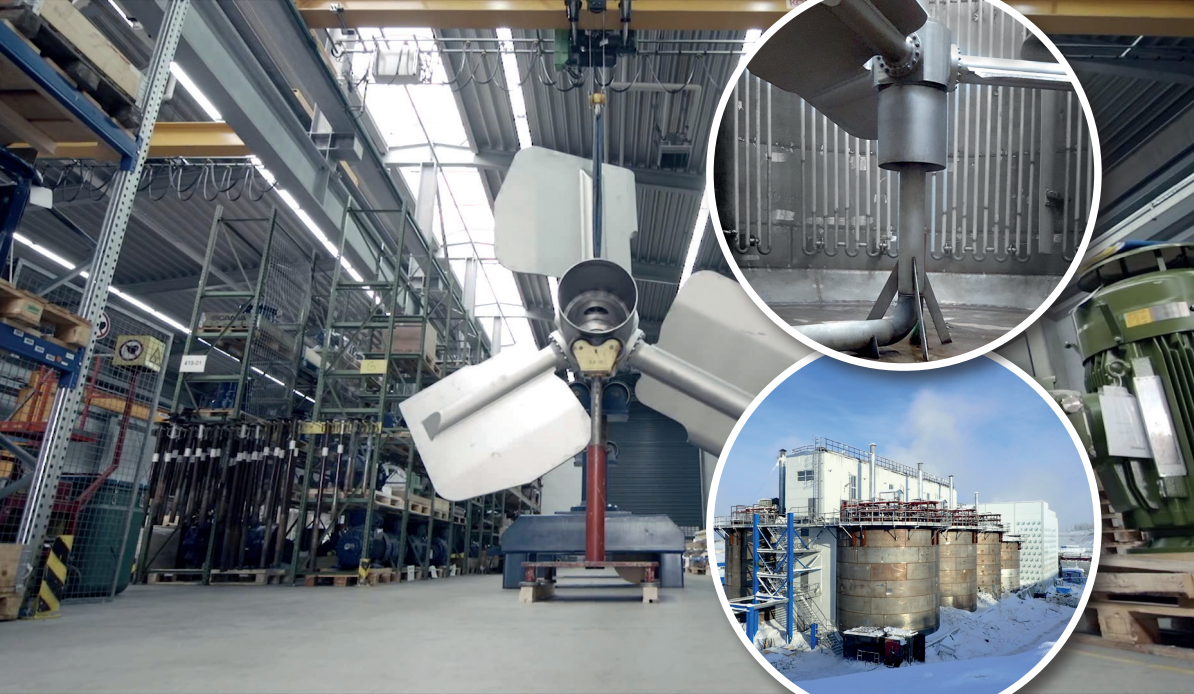

Our VISCOPROP and ISOJET-B hydrofoil impellers are ideal for low to medium gas rates. For high gas rates, the particularly efficient EKATO COMBIJET and EKATO COMBIJET PLUS solutions are used, which have a very low power loss even with high gas volumes and enable a cost- and energy-efficient agitator design.

Our optimized aeration concepts prevent flooding of the agitators and clogging of the aeration holes, which is a common problem with conventional aeration rings. The improved dispersion significantly increases the mass transfer, which leads to more efficient processes and shorter production times.

Overall, these advantages contribute to a significant reduction in the operating and maintenance costs of the system.

More info: https://www.ekato.com/industries/minerals-and-metals-processing/