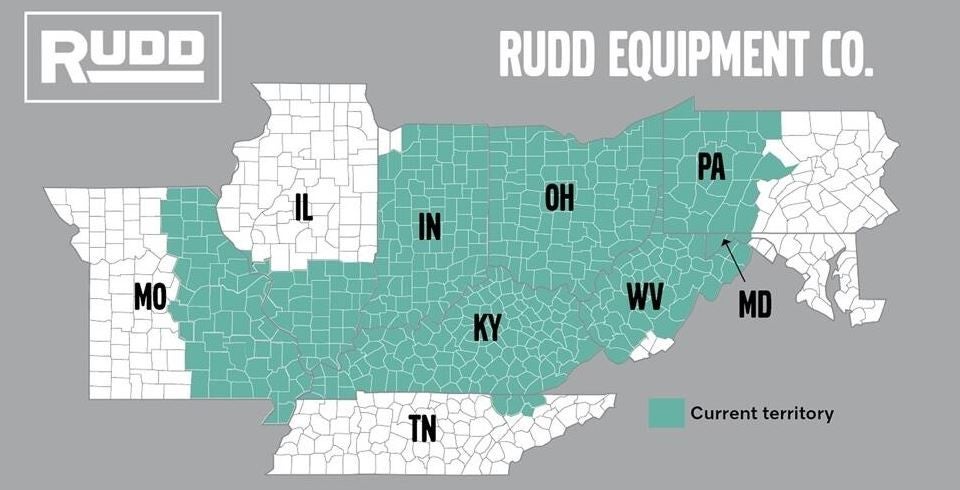

Rudd Equipment is the exclusive distributor in the US Midwest for international and preferred manufacturers including Volvo, Hitachi, Sandvik, Link-Belt, and Bergmann. For more than 70 years, the family-run firm has provided excavators, haulers, wheel loaders and other essential mining and construction equipment and repair services to seven US states: Kentucky, Indiana, Ohio, West Virginia, Western Pennsylvania, Southern Illinois and Eastern Missouri.

One of the biggest challenges for the rental and heavy machinery dealer, which was purchased last December by German-Based Ferronordic in a bid to expand into the US market, is to protect its fleet, reduce maintenance costs and optimise uptime.

“Our vehicles are operating in pretty dusty and dirty environments, either in underground mines or in tough conditions on construction sites, exposed to excessive temperatures and crushing tonnes of material like steel or concrete every day,” says Rudd’s parts manager Mike Upton. “Eventually, contaminants will damage the seals of the cylinders on the machines and then risk entering the hydraulic system through that weakness, corroding the valves and pumps. This is one of the biggest maintenance challenges we have.”

Upton estimates that a typical hydraulic cylinder has a lifespan of about 5,000 hours and repairing the seal costs about $8,000 to $10,000. Repairing a whole cylinder is another story, with a price tag of between $80,000 and $100,000.

A low-tech solution

Rudd Equipment can confidently tell its customers that its fleet can work for double the length of time without needing to service its cylinders – and that is a direct result of using a protective cylinder cover made by Fluid Control Services.

Upton says the company uses the boot-like cover, called the Seal Saver, on its entire fleet, proven to be effective on cutting down the ingression of dirt, oils and other pollutants in hydraulic cylinder systems.

“Rudd has been using the Seal Saver at least for 18 years, since I started this job. We always get good feedback from our customers and those companies who rent from us and then go on to buy their own equipment, they are completely converted.”

Resistant to heat, oil, chemicals, and water, the Seal Saver is manufactured in the US, from a wide range of materials, and is custom designed for each application to ensure the best protection for each machine.

“For equipment that is exposed to chemicals or high heat, the Seal Saver can be made from Kevlar, aluminised silica and other materials that are specifically designed to work in such harsh environments. The Velcro closure and wraparound design makes installation quick and easy—usually in 15 minutes or less—with no disassembly of the cylinder required,” explains Leigh Carlson, the CEO of Fluid Control Services. Carlson’s father invented the product to protect the cylinders in the wood product industry but soon realised its wider application potential.

She adds: “Mining companies are facing an expensive time in their transition to net-zero, investing in electric fleets as well as advanced technologies like AI, ML and internet-of-things for better data capture and improved decision making. The Seal Saver is a low-cost way to extend maintenance budget. Even after almost 40 years, it’s still unique and we are delighted about that.”

For more information on cost-effective ways to protect your heavy machinery, download the free paper below