Founded in 1997, and headquartered in Vancouver, WA, our team of engineers and process industry veterans continues to deliver on our promise of being the most intuitive and easy-to-use manufacturing decision support system available.

Mining operations hinge on maximising asset use and achieving the highest possible throughput, all within a capital-intensive framework. dataPARC stands as the connective tissue between diverse data sources, offering an intuitive toolkit that transforms complex data into actionable insights. Our analytical software streamlines decision-making and melds existing manual data entry and energy monitoring systems. This consolidation paves the way for expansion and secures a lasting return on investment, reinforcing the long-term value dataPARC brings to your mining enterprise.

Optimised process analytics for mining operations

Enhance mining efficiency and sustainability

Unlock the full potential of your mining operation with dataPARC’s cutting-edge process data analytics and visualisation toolkit. Designed specifically for process industries like mining, our solutions empower you to dramatically improve efficiency, productivity, sustainability, and asset reliability, ensuring optimal performance throughout your processes.

Self-service data intelligence

Take control of your mining operations with dataPARC’s self-service platform, crafted to help mine operators enhance quality, maximize yield, and fine-tune operations. Analyse and visualise IoT data from across your operations to make significant improvements and solve quality challenges with confidence.

Streamline operations management

Integrated data for informed decisions

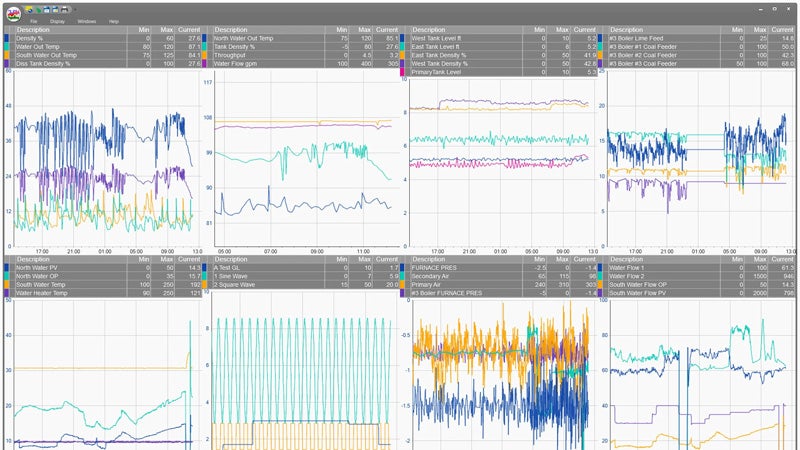

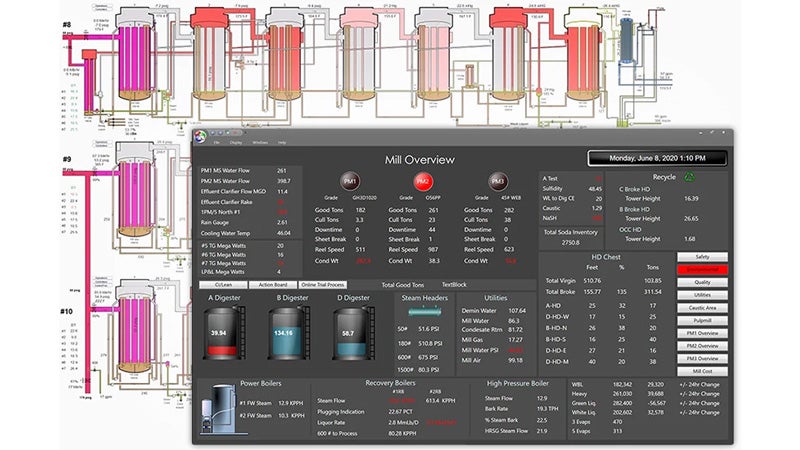

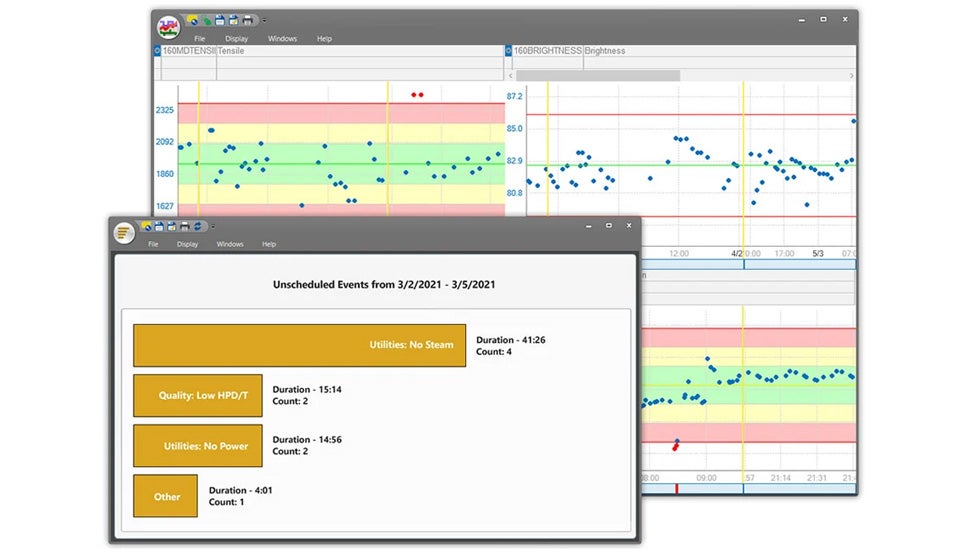

Harness the power to gather and access a wide array of plant data swiftly with dataPARC. Our system eradicates data silos, creating a cohesive data environment. Analyse your comprehensive data to pinpoint process optimisation opportunities and maintain optimal conditions with our real-time monitoring, control charts, and intelligent alerts.

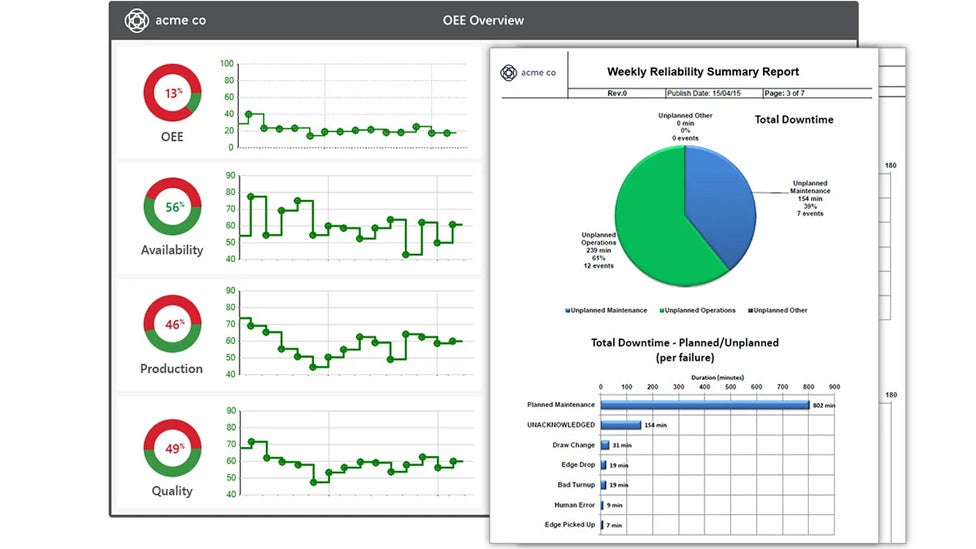

Empower operations teams

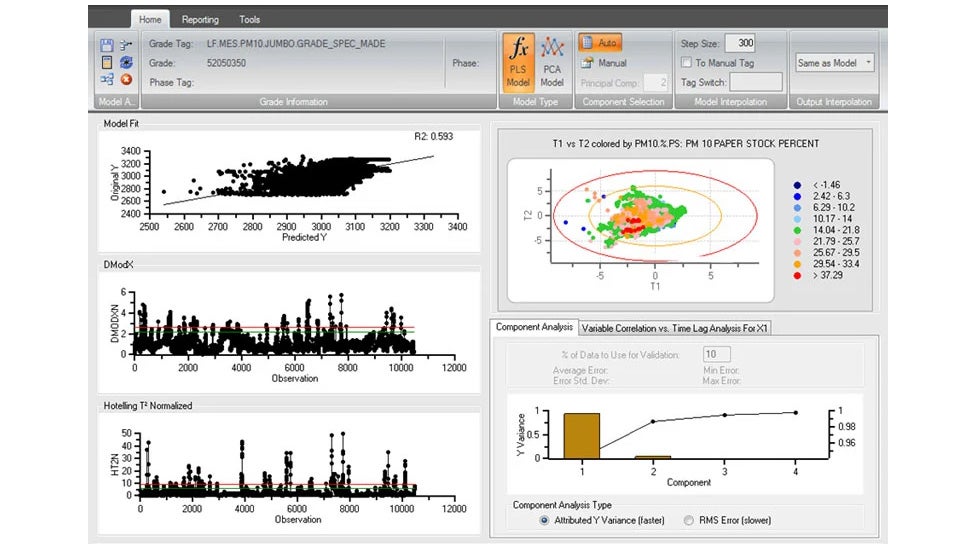

dataPARC equips your operations teams with the tools to make better, data-driven decisions. By minimising variability in costs and quality, and predicting downtime through advanced models, you can quickly identify and address process interruptions, fostering a culture of continuous improvement in your mining operations.

Advanced diagnostic and predictive analytics

Rapid troubleshooting and insightful visualisation

Leverage dataPARC’s superior diagnostic tools to mine deeper insights and resolve issues with unprecedented speed. Our rapid troubleshooting capabilities have proven their worth by identifying the origins of complex process issues in mere minutes. Our insightful process displays enable operators in the control room to spot and solve challenging issues without delay.

Proactive asset management

Utilize dataPARC’s advanced analytics to develop predictive models that provide greater visibility into your processes and improve asset management. dataPARC gives you the foresight to manage proactively.

Unified data ecosystem

Your centralised data hub

Turn to PARCview as the definitive hub for all your manufacturing data. It aggregates disparate data sets from multiple systems, including ERP, MES, lab, and quality systems, into actionable insights that drive continuous improvement. dataPARC supports integration from any data source, ensuring you can compile data from facilities worldwide into a single, unified view. Our platform’s compatibility with major historians allows you to connect and analyse data with unparalleled flexibility, establishing dataPARC as the cornerstone of your data-driven mining enterprise.